A New Method of

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

Comb-ating Cylinder Wear

Oil Positively Drawn Around the Entire Periphery of the Pistons by Engine Suction

FOLLOWING upon the conclusions drawn from the results of the experiments on cylinder wear carried out by the Institution of Automobile Engineers, and described in our issue dated June 23, additional interest should be aroused by a recent invention, the object of which is to combat cylinder wear by ensuring that the lubricant supplied to the pistons is evenly distributed around the whole of their bearing surfaces. The idea, so far as we know, is original in its conception; the principle strikes us as being clever and practical, and the mechanism employed is remarkably ingenious.

Protection from Corrosion.

That the evidence in favour of the corrosion theory is apparently conclusive does not diminish the importance of this invention. Apart from the many other claims made for it, the improved lubrication it affords will obviously, to a considerable extent, protect the cylinder walls from the attacks of the corrosive product of combustion.

Furthermore, the need for stiff scraper rings is lessened by reason of an incidental function of the apparatus, namely, the removal of the excess of oil that is drawn up between the pistons and cylinder walls under certain driving conditions.

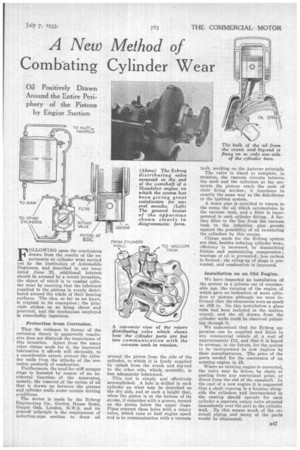

' The device is made by the Evbrog Engineering Co., Gordon House Road, Gospel Oak, London, N.W.5, and its general principle is the employment of induction-pipe suction to draw oil around the piston from the side of the cylinder, to which it is freely supplied by splash from the crank and big-end to the other side, which, normally, is less adequately lubricated.

This end is simply and effectively accomplished. A hole is drilled in each cylinder on what may be described as the dry side, and at such a height that, when the piston is at the bottom of its stroke, it coincides with a groove, turned on the piston below the upper rings. Pipes connect these holes with a rotary valve, which runs at half engine speed and is in communication with a vacuum talk working on the Antovac principle.

The valve is timed to complete, in rotation, the vacuum circuits between the tank and the cylinders at the moments the pistons reach the end a of their firing strokes ; it functions in exactly the same way as the distributor in the ignition system.

A drain pipe is provided to return to the sump the oil which accumulates in the vacuum tank, and a filter is incorporated in each cylinder fitting. A further filter in the line from the vacuum tank to the induction pipe guards against the possibility of oil re-entering the cylinders by this course.

Claims made for the Evbrog system are that, besides reducing cylinder wear, efficiency is increased, by diminishing fricton and maintaining compression ; wastage of oil is prevented; less carbon is formed; the oiling-up of plugs is prevented. and combustion is improved.

Installation on an Old Engine.

We have inspected an installation of the system in a private car of considerable age, the running of the engine of which gave no indication of worn cylinders or pistons although we were informed that the clearances were as much as .028 in. On this installation a glass tube had been included in the suction circuit, and the oil drawn from the cylinder walls could be observed pulsating through it.

We understand that the Evbrog apparatus can be supplied and fitted to any commercial vehicle at a cost of approximately £12, and that it is hoped to arrange, in the future, for the system to be incorporated in new engines by their manufacturers. The price of the parts needed for the conversion of an existing engine is £8.

Where an existing engine is converted, the valve may be driven by chain or gearing from any convenient point, or direct from the end of the camshaft. In the cast of a new engine it is suggested that a shaft running in a housing alongside the cylinders and incorporated in the casting should operate for each cylinder a separate rotary valve situated immediately over the port in the cylindet wall. By this means much of the external piping, and many of the parts would be eliminated.