E0 m Drivers &Mechanics

Page 17

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY is paid for the best communication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

Light Up Your Lamps at

5.7 on Thursday ; 5.8 on Friday ; 5.9 on Saturday ; 5.11 on Monday ; 5.12 on Tuesday ; 5.14 on Wednesday.

To Run with a Broken Valve Spring.

The sender of the follo.wing communication has been awarded the Ws. prize this week.

[1581] A.11.11. (Llandaff) writes :—" I have a considera,ble number of roadside repairs to do to commercial vehicles of all kinds, from light delivery vans to heavy lorries. It is, as may be imagined, quite a common experience for me to be faced with the

A fixture for use when a valve spring breaks.

problem of getting a vehicle home under very awkward conditions. These are very often aggravated by lack of the necessary tools or spares.

The enclosed sketch [We have had this redrawn.— ED.I illustrates a, handy fixture which I have found very useful on several occasions. It is of service when a valve spring is found to be broken, and can be made from the lid of an Oleo sparking-plug box and a piece of sheet brass TIT in. thick. The brass must be cut in the shape of a circle 1 in. diameter, and fastened to the box lid by means of three wood screws. A I in. hole should be drilled through the centre to receive the valve stem.

"To use it, first of all take out the valve cotter and remove the spring collar, take away the smaller piece of broken spring and replace by the fixture, which is slipped over the valve stem brass side up. Refit the collar and cotter, and start the engine up. "It will be found possible to run a good distance with this contrivance in use, though, of course, no time must be lost before getting a new spring and fitting same.

"I have found this little fixture very handy; and, if made as described, it will be possible touse it on most of the engines.in general use."

A Makeshift Steering Arm.

[1582] " H.M.11 (West Bromwich) writes : —" After waiting three weeks for a drop forging of a steering arm, which even then did not arrive, I decided to make one with the best material to hand. The replacement was rendered necessary owing to the old one being very much worn. In addition, as all the connecting parts were also worn, it was decided to make the new one to fit the remainder of the existing

parts. For instance, the holes in the arm were larger, and it proved necessary also to enlarge the tapered end of the lever to suit the hole in the axle arm.

"As no forging was obtainable, I adopted the following means, which were the best I had at hand, and as our purpose was well answered, I shall never, on a similar occasion, wait so long again for parts ; time, in our business, being all-important, a saving in this direction very often more than compensates for any extra expense involved.

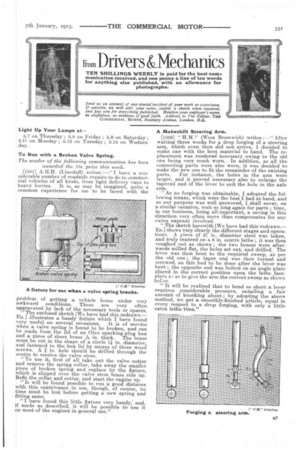

"The sketch herewith [We have had this redrawn.— ED.] shows very clearly the different stages and operations. A piece of 2 in, diameter steel was taken, and truly centred on a 6 in. centre lathe ; it was then roughed out as shown ; the two bosses were afterwards milled flat, the holes set out, and drilled. The lever was then bent to the required sweep, as per the old one the taper end was then turned and screwed, as ihis had to be done after the lever was bent ; the opposite end was bolted on an angle plate placed in the correct position upon the lathe faceplate s.) as to give the arm the correct sweep as shown bellw.

"It will be realized that to bend so short a lever requires considerable pressure, entailing a fair amount of knocking about ; by adopting the above method, we get a smoothly-finished article, equal in every respect to a drop forging, with only a little extra lathe time."