Oil distribution: just the job for road

Page 56

Page 57

Page 58

If you've noticed an error in this article please click here to report it so we can fix it.

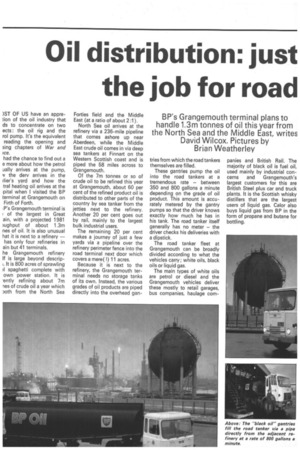

BP's Grangemouth terminal plans to handle 1.3m tonnes of oil this year from the North Sea and the Middle East, writes David Wilcox. Pictures by Brian Weatherley

)ST OF US have an appretion of the oil industry that ds to concentrate on two ects: the oil rig and the rol pump. It's the equivalent reading the opening and sing chapters of War and we.

had the chance to find out a e more about how the petrol Jelly arrives at the pump, v the dery arrives in the ilier's yard and how the tral heating oil arrives at the pital when I visited the BP terminal at Grangemouth on Firth of Forth.

,P's Grangemouth terminal is

of the largest in Great am, with a projected 1981 )ughput of about 1.3m nes of oil. It is also unusual hat it is next to a refinery — has only four refineries in am n but 41 terminals.

he Grangemouth refinery If is large beyond descrip1. It is 800 acres of sprawling 0 spaghetti complete with own power station. It is .ently refining about 7m les of crude oil a year which aoth from the North Sea

Forties field and the Middle East (at a ratio of about 2:1).

North Sea oil arrives at the refinery via a 236-mile pipeline that comes ashore up near Aberdeen, while the Middle East crude oil comes in via deep sea tankers at Finnart on the Western Scottish coast and is piped the 58 miles across to Grangemouth.

Of the 7m tonnes or so of crude oil to be refined this year at Grangemouth, about 60 per cent of the refined product oil is distributed to other parts of the country by sea tanker from the jetties next to the refinery. Another 20 per cent goes out by rail, mainly to the largest bulk industrial users.

The remaining 20 per cent makes a journey of just a few yards via a pipeline over the refinery perimeter fence into the road terminal next door which covers a mere( !) 11 acres.

Because it is next to the refinery, the Grangemouth terminal needs no storage tanks of its own. Instead, the various grades of oil products are piped directly into the overhead gan

tries from which the road tankers themselves are filled.

These gantries pump the oil into the road tankers at a tremendous rate — between 350 and 800 gallons a minute depending on the grade of oil product. This amount is accurately metered by the gantry pumps so that the driver knows exactly how much he has in his tank. The road tanker itself generally has no meter — the driver checks his deliveries with a dipstick.

The road tanker fleet at Grangemouth can be broadly divided according to what the vehicles carry; white oils, black oils or liquid gas.

The main types of white oils are petrol or diesel and the Grangemouth vehicles deliver these mostly to retail garages, bus companies, haulage corn

panies and British Rail. The majority of black oil is fuel oil, used mainly by industrial concerns and Grangemouth's largest customers for this are British Steel plus car and truck plants. It is the Scottish whisky distillers that are the largest users of liquid gas. Calor also buys liquid gas from BP in the form of propane and butane for bottling. BP vehicles are actually painted in these colours which explains why some BP tankers are black while others are white. At Grangemouth there are 32 white tankers and 32 black tankers, plus 18 liquid gas tankers.

But the terminal yard is also frequented by road tankers of a totally different colour — those of other, rival oil companies. They buy oil products from BP for sale under their own name and roughly 35 per cent of the terminal's throughput leaves in these non-BP vehicles.

Because the Grangemouth terminal distributes the whole range of BP oil products (with the exception of bitumen and lubricants) the road tankers are visiting a wide range of custo mers; factories, industrial plants, garages, schools, hospitals, marketing distributors, airports, bus and haulage companies and farms.

The characteristics of the customer dictate the type of vehicle used on the delivery, which in turns dictates the fleet mix of artics and rigids. Work-study engineers carry out a periodic review of all the customers to find out what size of vehicle is most suitable for each customer's usual drop.

Many orders these days warrant the use of 32-ton artic problems for a full-size a Therefore, the curl Grangemouth fleet compr 54 artics and 28 rigids.

The 32-ton artics have 6,: gallon tanks with either si) seven compartments of -; 1,000 or 1,100 gallons This configuration is chaser BP and built to order by tanker manufacturers. smallest compartment is gallons although the term will deliver an order as smal 200 gallons if necessary. type of split delivery is encouraged though, becE the dipstick alone is the ( way of measuring the deliv Smaller deliveries are madE BP's marketing distributors.

Incidentally, although inv ing and dipstick calibration litres and BP officially work litres, many customers with gallons and this meas ment is still widely used.

The Grangemouth termin well on its way tow standardisation on Sed Atkinson vehicles — the 300 and 200-Series can pro the basis for all sizes of tan tion chosen for the 400les units is the Cummins 30 or the 250 Turbo. ReAlity and longevity are two of main requirements, but just .:ause it has an unlimited )ply of dery this doesn't mean t BP casts fuel economy to wind. The terminal pays for dery like everybody else. 3P, like other oil companies tery weight conscious when comes to its 32-ton-gvw cs. Although the tankers +e a nominal capacity of 00 gallons, the weight of the duct often restricts the utition of this capacity. For tance, about 6,100 gallons petrol is on the 32-ton-gvw it while only 5,250 gallons of I oil is possible.

;o if the Armitage Inquiry's Dmmendation of an increase 34 tonnes on the existing 3 configuration is adopted, would be very much appreed in the oil distribution ustry.

he tanks themselves are Jominantly in aluminium by impson Tankers, Gloucester or Butterfields. The liquid vehicles have manganese :I tanks for sheer strength safety in the event of an ident. The discharge pipes :he tankers that carry fuel oil lagged to maintain the perature of the oil which is led at 125-140 degrees renheit so that it flows ly.

3rikers at Grangemouth er around 40,000-50,000 • a year and the average t age is four years. Instead of Ing a set age or mileage at eh vehicles are replaced, the itenance cost of each cle is considered. So if a -year-old unit is costing e to maintain than a six-old one one it's the newer one goes.

le area served by the eigemouth terminal is been the English-Scottish borand a line drawn across veen Oban and Perth, which Dmpasses 1,700 customers. average, a driver will make e deliveries a day, usually • in two trips and so ;lying a return trip to the iinal during the day.

us high percentage of empty ling during the return trip to terminal is the bain of the distribution business, but a is no way round it — there aren't many return loads In oil tanker!

any deliveries are relatively P Mlacrinvo arid Fri n rei by early men at 6.30 a.m. and going out again mid-afternoon with late shift men. More distant deliveries will take the whole day, but it is mostly the liquid gas tanker drivers covering the Northern part of Scotland that have nights out.

The Grangemouth terminal has a computer link with the main BP computer in Hemel Hempstead and this has paid dividends in terms of recordkeeping, wages and management information. It has made the invoicing particularly neat.

When a customer rings up with his order the relevant information such as type of product, number of gallons/ litres and requested delivery day matically retrieves all the orders for delivery that day and prints them out as delivery notes.

These will also include all relevant delivery information such as standard running time from Grangemouth to the customer, the standard delivery time allowed for the drop plus any special delivery instructions such as a height restriction owing to a low canopy.

To retrieve so much information at the touch of a button means that it must have been fed into the system in the first place and BP has done extensive work study to establish these delivery standards for each and every customer.

Generally, the traffic planning deliveries to be made normally within 24 hours of the request. Deliveries to hospitals, schools and prisons receive top priority.

But number one priority throughout the terminal and the refinery is of course safety. No Smoking signs seem to adorn every square inch of wall space and a fully laden foam tanker is kept in the terminal yard. The refinery even has its own fire station.

All drivers must have HGV Class 1 experience before they join BP, even if they are only to drive a rigid tanker. They also have a three-month training period before they are put on normal driving duties. Even experienced drivers go away for occasional refresher courses at BP's own training establishment at Kingsbury near Tamworth. This training covers safety and legal requirements as well as pure driving and as a result produces a driver of an allround high standard.

And if you think that's just a