From the Omani Boer

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

by Graham Montgomen

THE PROPOSALS for increased gross vehicle weights put for ward by the Armitage committee will obviously have farreaching effects on the transport industry if they become accepted as legislation.

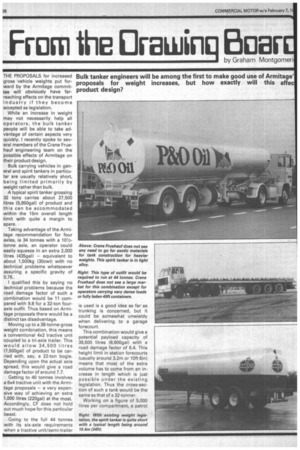

While an increase in weight may not necessarily help all operators, the bulk tanker people will be able to take advantage of certain aspects very quickly. I recently spoke to several members of the Crane Fruehauf engineering team on the possible effects of Armitage on their product design.

Bulk carrying vehicles in general and spirit tankers in particu lar are usually relatively short, being limited primarily by weight rather than bulk.

A typical spirit tanker grossing 32 tons carries about 27,500 litres (5,950ga1} of product and this can be accommodated within the 15m overall length limit with quite a margin to spare.

Taking advantage of the Armitage recommendation for four axles, ie 34 tonnes with a 101/2

tonne axle, an operator could easily squeeze in an extra 2,000 litres (435ga1) — equivalent to about 1,500kg (30cwt} with no technical problems whatsoever assuring a specific gravity of 0.76.

I qualified this by saying no technical problems because the

road damage factor of such a combination would be 11 compared with 9.8 for a 32-ton four axle outfit. Thus based on Armitage proposals there would be a distinct tax disadvantage.

Moving up to a 38-tonne-gross weight combination, this means a conventional 4x2 tractive unit coupled to a tri-axle trailer. This would allow 34,500 litres (7,500gal) of product to be carried with, say, a 22-ton bogie. Depending upon the actual axle spread, this would give a road damage factor of around 7.7.

Getting to 40 tonnes involves a 6x4 tractive unit with the Armi tage proposals a very expen sive way of achieving an extra 1,000 litres (220ga1) at the most.

Accordingly, CF does not hold out much hope for this particular beast.

Going to the full 44 tonnes with its six-axle requirements when a tractive unit/semi-trailer is used is a good idea as far as trunking is concerned, but it could be somewhat unwieldy when delivering to a garage forecourt.

This combination would give a potential payload capacity of 39,500 litres (8,600gal) with a road damage factor of 6.4. This height limit in station forecourts (usually around 3.2m or 10ft Gin} means that most of the extra volume has to come from an increase in length which is just possible under the existing legislation. Thus the cross-section of such a tank would be the same as that of a 32-tonner.

Working on a figure of 5,000 litres per compartment, a petrol tanker taking advantage of the Armitage proposals would simply have more compartments. Otherwise there would be no extra internal modifications.

These statistics ignore the maximum quantity of petrol permitted by the Home Office to be carried in one tank, but they do serve to illustrate the point.

Currently the tanker length of a 32-ton outfit is just under 10.4m (34ft) while a semi-trailer tanker to operate at the full 44 tonnes would need to go up to the full 1.2.2m (40ft).

The static and fatigue stresses in a tank do not vary very much between a 32 and a 34-tonner or even a 38-tonner, but there is a considerable difference in stress level at 40 and 44 tonnes. Taking a stress level factor of unity for the 32-tonner, this rises to 1.5 for the 40-tonner and to 1.7 for the maximum 44-ton version.

These figures are all for aluminium tanks. However, the general features for steel will be about the same. Crane Fruehauf does not think that there is any 'teed to go to exotic materials for tank construction. If anyone was worried about an increase in stress level, it would be a simple matter to increase the material thickness.

CF does not see a conversion market for tanks because with the time and expense it would make more sense to go for a new vehicle.

Obviously a bulk tanker — especially one for hazardous loads --must be strong enough to resist impact damage in the case of an accident. In fact tanks rarely get punctured — "they crease nicely", according to Geoff Can non, senior product development engineer. The fittings, however, can get knocked off.

Overall then, the design of the bulk tanker for coping with any increase in gross weight is not going to present any problems. "They're just going to get longer," says Geoff Cannon. Environmentalists note: "Get longer" in this context only means going up to the maximum length already permitted in the UK.

As far as the Armitage proposals for goods vehicles in general are concerned, Crane Freuhauf is not greatly worried. "We have the configurations sorted out to meet the various proposals," said John Crane, CF's technical liaison director.

It' is interesting that the CF engineers are not full of enthusiasm for the 40-tonne tractive unit/semi-trailer combination as with a 6x4 and a tandem-axle trailer it is possible to get a badly proportioned outfit with a high load on the kingpin. This is not good for roll stability and is consequently poor on cornering.

According to Crane Fruehauf, while ay suspension is the ultimate springing medium for trailers it is also expensive. Air can improve the ride while at the same time maintaining roll stability.

Soft leaf springs, however, give an improved ride at the expense of roll stability. In John Crane's view if the Department of Transport lays. down regulations for softer suspension it might be cheaper to go for fullair suspension rather than soft leaf springs with lots of anti-roll bars.

vehicles or the roads which need improving. Engineering director Barry Widclowson summed it up neatly when he said: "We must separate the aspects which have known design solutions from those which people would like in theory."

Crane Fruehauf has already had requests from customers to modify their trailers in line with the Armitage proposals proving that some people do not understand what the report was all about. The line the company is taking is that if a customer wishes CF to produce a trailer "to the Spirit of Armitage" then this will be done, but obviously no one can guarantee that this will meet the final post-Parliamentary proposals.

If the 38-tonne proposals are accepted then Crane Fruehauf expects that there will be a good market for trailer conversions. Accordingly the company has engineered a conversion package to build a tri-axle trailer from a tandem. Again, however, CF is quick to point out that it cannot guarantee that the design will qualify when the final legislation comes through.

The way the Crane Fruehauf suspension systems are designed, there are certain identical components. Thus in many cases it is merely a case of taking off part of the existing suspension and adding a third axle with certain structural additions over the suspension area. It is a fairly straightforward conversion job although a lot depends on whether the operator has decided to have two kingpin positions or to move the original one.

So far there has been minimal operator interest in a steering third axle. The reason is thought to be that complication is ni something people want trailers.

As John Crane expl,aine4 "We of the trailer industry a more anxious and interested getting heavier weights than tf truck people. Everything over tons will involve some sort trailer."

"Some sort of trailer" ol viously begs the question as what will be the future drawb, market situation. Being an inte national company the FrOehai organisation has factories sca tered around the globe and z such has easy access to inc vidual market statistics. Takir Western Europe as a who Fruehauf has noticed a constai shift towards the semi-trail( type of operation. In 1977 th survey showed a slight but del nite trend away from drawbar This was in absolute terms E the drawbar market is not di clining as such, but the numb( of semi-trailers is increasing s the ratio is being altered.

With heavy vehicle brakin! this issue is one in which there a limit in today's state-of-art pe formance. The Armitage repo is looking for something bett( than the EEC directive and to th aim has acknowledged thz stopping distance is what it's e about.

Crane Fruehauf is going f( better response times and in proved balance with the form' providing the biggest scope f( improvement.

According to John Crane, or of the biggest problems t1. company is having is trying I get greater operator acceptanc of anti-skid systems. "Load al portioning is one thing but can't be as good as anti-ski which gives its best perforn ance in a high-risk situation."

A trailer fitted with an anti-ski system can operate only wit tractive units so fitted, so CF trying to get it to operate via th stop lamp circuit thus allowing trailer system to operate on it own. A change in EEC and Cor struction and Use proposals wi come in in October 1982 whic will lay down the braking pe, formance for a trailer as vehicle in its own right.

The safety advantages of th anti-skid system are nc necessarily measurable in term of stopping distance. The advar tages can be exploited part lz den and on wet surfaces. A Barry Widdowson put it "People don't necessarily hay accidents in good weather an that's how stopping distance are measured."