THE PASSENGER CHASSIS )F THE FUTURE

Page 112

Page 113

Page 114

If you've noticed an error in this article please click here to report it so we can fix it.

E. NGINEERS, especially those employed in development work, can be divided into two classes—those who are sound but orthodox, and the others who are unorthodox and may, or may not be. sound. The former can be left alone in an experimental department to work out their own salvation, as it were, but, whilst the people comprising the latter type are usually brilliant, a tight rein has to be kept on their activities, or the commercial side of the business, with which they are connected, may become chaotic.

The foregoing is rather a roundabout way of saying that the commercial side of any engineering enterprise is. nowadays, the main factor governing design, much as the designers themselves would like to :have the conditions reversed. Thus, in making any attempt to forecast future technical development, especially of such a commertialized article as a passenger chassis, the mind of the public, which instinctively recoils from anything revolutionary, has to be taken into account.

Drastic Changes Unlikely Yet.

One may say then, that, for the immediate future, development work in the commercial-vehicle industry is likely to continue along orthodox lines, improvements being incorporated at the dictates of fashion and expediency. No drastic changes may be anticipated, at least, for the next few years.

To some extent design has become "cut and dried," despite the great 'variety of individual chassis (each different from the other) available at the present time. As an instance of this state of affairs, the chassis frame itself may be mentioned. In practically every model, made for either bus or coach bodywork, two side-members, each with a kick-up over the front and rear axles, are used, in conjunction with channel or tubular-section cross-members.

Again, transmission systems, from the rear of the gearbox, also follow each other fairly closely, the axle, or axles, being equipped with worm or bevel drive with the pots located centrally or to one side in the casing.

c58

with the transmission system, and, as the minimum height for the floor of a vehicle is determined by the size of the axle pot, it follows that a new form of transmission might bring in its train a new frame formation. Already there are many indications that the clashingpinion gearbox will be superseded before long.

Furthermore, with the marked activities in the private-car world in the development of individual wheel suspension, the stage seems to be set for the consideration of front-Wheel drive.

By adopting a layout something on the lines indicated in one of the drawings accompanying this article, an attractive frame can be evolved which would give an appreciably lower floor height, would be simpler to produce in quantities and would afford more effective support to the body than do current designs of chassis. Using a box-girder frame (as in the illustration) the floorboards could almost be laid on the

frame itself, whilst the body sides could quite easily be built up from die chassis without utilizing a sill.

So far as the power-unit is concerned, there do not appear to be any practical difficulties in producing a short, flat eight-cylindered engine with the auxiliaries so arranged that the overall height is small, thereby allowing the unit to fit in between the main frame sides below the floor of the vehicle. The additional seating accommodation provided in this way would be invaluable in both buses and coaches.

One must not forget that, at the Commercial Motor Show in November last, the Bristol concern exhibited an axial engine operating on the wobbleplate principle, the layout being such that all the dimensional requirements of the scheme outlined above are met.

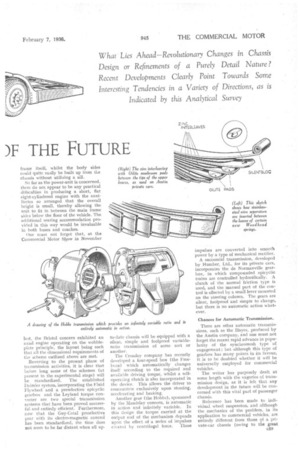

Reverting to the present phase of transmission activities, it is clear that before long some of the schemes (at present in the experimental stage) will be standardized. The established Daimler system, incorporating the Fluid Flywheel and a preselective epicyclic gearbox and the Leyland torque converter are two special transmission systems that have been proved successful and entirely efficient. Furthermore, now that the Guy-Cotal preselective gear with its electro-magnetic control has been standardized, the time does not seem to be far distant-when all up to-date chassis will be equipped with a silent, simple and foolproof variableratio transmission of some sort or another.

The Crossley company has recently developed a four-speed box (the Freeborn) which automatically changes itself according to the required and available driving torque, whilst a selfoperating clutch is also incorporated in the device. This allows the driver to concentrate exclusively upon steering, accelerating and braking.

Another gear (the Hobbs), sponsored by the Maudslay concern, is automatic in action and infinitely variable. In this design the torque exerted at the output end of the mechanism depends upon the effect of a series of impulses created by centrifugal force. These impulses are converted into smooth power by a type of mechanical rectifier. A successful transmission, developed by Humber, Ltd., for its private cars, incorporates the de Normanville gearbox, in which compounded epicyclic trains are controlled hydraulically. A clutch of the normal friction type is used, and the manual part of the control is effected by a small lever mounted on the steering column. The gears are silent, foolproof and simple to change, but there is no automatic action whatever.

Chances for Automatic Transmission.

There are other automatic transmissions, such as the Hayes, produced by the Austin company, and one must not forget the recent rapid advance in popularity of the synchromesh type of engagement but although this type of gearbox has many points in its favour, it is to he doubted whether it will be universally employed for commercial vehicles.

The writer has purposely dealt at some length with the vagaries of transmission design, as it is felt that any development in the future will be concerned with this vital part of passenger chassis.

Reference has been made to individual wheel suspension, and although the mechanics of the problem, in its application to commercial vehicles, are entirely different from those c?f a private-car chassis (owing to the great

discrepancy in weight with relatively small dimensional differences) there are methods of overcoming the difficulties that are likely to be encountered. With the speed restrictions now in operation, steering troubles are not marked, but the writer's experiences with private cars lead him to believe that the system offers a number of important advantages. One might justifiably expect that, before long, commercial-vehicle manufacturers will, at any rate, be experimenting in this direction, not necessarily for double-deck buses, but for long-distance coach chassis.

Whilst dealing with the subject of suspension, recent developments in the manufacture of springs themselves may be mentioned. Certain Woodhead designs now incorporate between the leaves stainless-steel separators, which tend to maintain the internal damping of the spring at a constant level throughout the life of a vehicle. Another development in this direction is sponsored by the Austin concern, Oilite disc inserts being placed between the tips of the top leaves of the spring for a similar purpose; this is in addition to zinc interleaving..

Finally the question of brakes arises. The standard of braking in modern passenger vehicles is high. Indeed, it is no exaggeration to say that designers have reached the point where they have to modify their design to suit the capacity of passengers to resist rapid deceleration. At certain speeds, and on most chassis, it is possible to obtain retardation at the rate of 20 ft. per second at certain speeds, and, as this is somewhat uncomfortable for passengers, the full capacity of the braking system is seldom used by the driver. 1 his being so, future development will be concerned more with matters relating to maintenance and service work generally than with enhanced efficiency.

Servo systems have certainly come to stay, but, as with everything else, an action that is rendered easy is often abused by excessive use. As a result, frequent adjustment of the shoes and linkages is demanded. This has led the Daimler engineers to produce an automatic adjuster which maintains the desirable clearance between the shoes and the drums throughout the life of the brake facing. Wider application of such principles is bound to ensue in the not-far-distant future.