MAINTAINING AN

Page 102

Page 103

Page 104

If you've noticed an error in this article please click here to report it so we can fix it.

IMPORTA 'qr1-9 PASSENGER FLEET IT is always interesting to compare the maintenance methods employed by various operators. Some adhere to the principle that a vehicle, irrespective of its mileage, should be docked so often and completely overhauled at longer fixed periods. Others never carry out an overhaul in the strict sense of the word, but work entirely on the unit-replacement system, only comparatively minor jobs being done with the original units in position.

Amongst the important users adopting the latter system is the Northern General Transport Co., Ltd., Queen Street, Bensham, Gateshead-on-Tvne. This company, which is most efficiently organized, covers a fairly large and congested area, and has working arrangements for the linking up of services with other operating concerns. In this article, however, we do not propose to deal with the organization of the services so much as with the conditioning of the vehicles.

Centralized Repair Depots.

The central repair works is situated at Bensham, whilst there are auxiliary works at Stanley, which•does major dockings for the Consett depot ; Chester-le-Street, which works for the depots at Murton and Sunderland ; South Shields, which is independent, and a Bensham service depot which does its own work.

c43 Each has a Morris-Commercial 30Cwt. van for carrying spares, going out to breakdowns, etc. There is also a Thornycroft 2i-ton lorry on general work and a Daimler Y-type which acts as a breakdown vehicle. Serious breakdowns are, however, so few that a crane-equipped vehicle has not been found necessary.

Dockings Based on Mileage.

Dockings are based entirely on mileage—minor ones at every 6,000 miles and major dockings at -various mileages up to 25,000, according to the routes, those vehicles operating on difficult routes receiving more frequent

attention. The actual period be tween the major dockings are really determined by the weakest link, which is generally the brakes. During the minor dockings the engines are decarbonized and the valves attended to, brakes inspected and adjusted and smaller detail repairs effected.

At the major dockings the cylinders and cylinder heads are removed, the lower halves of the crankcases dropped; gearboxes and transmissions inspected, axle shafts and differentials withdrawn, the wheels removed, all brakes adjusted and the shoes refaced where necessary ; dynamos are removed and the magnetos very thoroughly examined and tested, being changed if they are not up to standard.

In the case of a breakdown on the road, the driver or conductor is not expected to do anything to the vehicle, but to telephone to the nearest Northern depot. The farthest paint at which this may have to be done on the various routes is from 15 to

20 miles. Some of the routes are longer than this, as in the case of the service from Easington to West Hartlepool, and others towards the South, which are operated in conjunction with the United concern, the driver or conductor then telephoning to the nearest United repair depot in that area.

Equipment For Maintenance Work.

The equipment for the main repair depot includes Manley Page hydraulic jacks for four wheels, Black and Decker valve grinders. Hall valve-seat grinders for stelae seats, Richards boring machines for crankcases, a universal grinder by Brown and Sharpe, and a Churchill surface grinder. Crankshafts are reground on a Landis machine, and all parts of vital importance, such as axle shafts, steering arms, etc., are carefully „tested for cracks on an ECO detector supplied by the Engineering and Equipment Company. Brake drums are ground and shoes refaced on equipment supplied by Bradbury, of Braintree. Some of the smaller items, including the ECO crack detector, are duplicated at the other depots. Electric and acetylene welding is carried out and the radiators of the side-engined vehicles built throughout.

Electrical and Other Repairs.

One section is devoted to oil injection pumps and injector nozzles, and has C.A.V.-Bosch testers for each. Cylinders are bored out on a Stormizer machine to the extent of .03 in., but hardened liners are honed on a Hutto machine. Dynamos are repaired and rewound, hut whilst magneto'S receive ordinary repairs, rewinding of the armatures is not carried out. For testing the latter, big spark gaps are employed, which is practically equivalent to operating the spark under compression.

A simple but efficient tool which we noted at Bensham was a pneumatic riveter fitted up ,f or panel-beating.

Great care has to be taken in the overhauling of engines, because these cannot be nursed for a few days, as in the case of private cars, but are all out from the start. They are tested with an air dynamometer, a standard speed being set for each type of engine, and the unit is not apprcived until it works up to this.

Crankshafts are ground when they are found to be .005 in. to .006 in. oval. In the remetalling of big-ends, the most satisfactory metal, so far, has been found to be Hoyt No. 11, but experiments are being carried out with lead-bronze.

Tyres are used on a mileage contract and serviced by the makers' fitters at the Northern depots, Dunlop and Goodyear supplying about 45 per cent. each, the remainder being of several makes.

The Maintenance of Bodywork.

Considerable attention is devoted to the maintenance of bodywork. Most of the recent bodies are by Short or \Veymann, Bodies come in for a complete repaint after approximately 21 months, this being done by selection.

In addition, the main depot carries out the complete reconditioning and bringing up to date of older types where the bodies are in good condition structurally. For example, some of the S.O.S. six

year-old vehicles for the Liverpool express service are having the body panels extended downwards at the sides, and heading, etc., added to give a streamline appearance, whilst extra sweeping panels are added at the sides of the bulkhead.

Each vehicle is estimated to have a life of 10 years; representing an average mileage of between 350,000 and 400,000. The maintenance cost is slightly under id. per mile. During the past year there were 122 failures resulting from mechanical defects, an average of one per 111,422 miles.

The efficiency of modern tyres is shown by the fact that in 1938 the total mileage lost throughout the fleet, as a result of tyre failure, was 32, an average of 426,314 miles per failure.

Details of the Fleet.

The total fleet numbers 446 vehicles, of which 40 are coaches, and, owing to the numerous low bridges in parts of the area, only 33 double-deckers can be employed. More than half of the buses are of S.O.S. make, whilst 31 saloon buses and six coaches utilize the S.E.6 side-engined chassis, designed throughout by the company. This model has proved most effective. The first experimental type has already run for over 180,000 miles, and nothing has happened to cause anxiety.

The weather conditions in the area are often severe. Some routes climb to considerable heights, where snow is frequently found, and interesting tests for adhesion have been carried out on snow with six-wheelers. It was found that a vehicle driving on all four rear wheels did not perform so well as a similar type driving on the forward pair, but having a special auxiliary damper-spring arrangement which prevents excessive movement of the balance beam between the front and rear springs of the bogie. The side-engined model has proved of great value in simplifying maintenance. The engine, clutch, gearbox and universal joints are immediately accessible from the outside, and during repairs the doors of the body can actually be locked so that there is no danger of the interior of the vehicle being soiled. Cylinder heads can be removed and valves attended to without otherwise disturbing the engine.

In test runs, which we made on both a bus and coach of this type (and in which, incidentally, we climbed and descended gradients of 1 in 8), other advantages of the side arrangement became apparent. All the seats can face forward, and in the bus 44 persons are accommodated in this manner, there is one gangway, without obstruction for its whole length, and dropped about 2 ins, below the seat platforms, whilst immediately above the power unit is another 2-in, platform, which comes under the seats and is barely noticeable.

Even when riding immediately above the engine there is no additional vibration—in fact, without previous knowledge, it would be almost impossible to say where the engine is situated.

At the Stanley depot, where an extension has recently been made, a fine set of pits has been installed. There are five pits in a row, with a gangway at the same level facing them and containing a long bench and vices. The finish is in white glazed brick and Holophane lights are mounted in wall recesses. Large storage space is provided between each pair of pits. It is intended in future extensions to carry the windows right down to the floor level and to use separate benches, so giving even better natural lighting. We have not yet said anything regarding spring repairs. These are all carried out by the Woodhead concern, which collects and delivers.

The maintenance charting system is of a simple but most effective type, c50

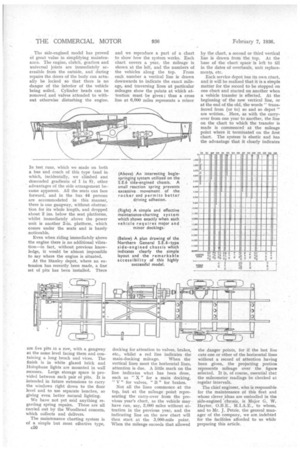

and we reproduce a part of a chart to show how the system works. Each chart covers a year, the mileage is shown at the left, and the numbers of the vehicles along the top. From each number a vertical line is drawn downwards to indicate the exact mileage, and traversing lines at particular mileages show the points at which attention must be given ; thus a cross line at 6,000 miles represents a minor docking for attention to valves, brakes, etc., whilst a red line indicates the

main-docking mileage. When the vertical lines meet the horizontal lines, attention is due. A little mark on the line indicates what has been done, such as " X " for a main docking, "

V" for valves, "B " for brakes.

Not all the lines commence at the top, but at the mileage point representing the carry-over from the previous year's chart, as the vehicle may have run, say, 3,000 miles without attention in the previous year, and the indicating line on the new chart will then start at the 3,000-mile point. When the mileage exceeds that allowed by the chart, a second or third vertical line is drawn from the top. At the base of the chart space is left to fill in the dates of overhauls, unit replacements, etc.

Each service depot has its own chart, and it will be realized that it is a simple matter for the record to be stopped on one chart and started on another when a vehicle transfer is effected. At the beginning of the new vertical line, or at the end of the old, the words "transferred from (or to) so and so depot" are written. Here, as with the carryover from one year to another, the line on the chart to which the transfer is made is commenced at the mileage point where it terminated on the first chart. The system is elastic and has the advantage that it clearly indicates the danger points, for if the last line cuts one or other of the horizontal lines without a record of attention having been given, the projecting portion represents mileage over the figure selected. It is, of course, essential that the mileometer readings be checked at regular intervals.

The chief engineer, who is responsible for the maintenance of this fleet and whose clever ideas are embodied in the side-engined 'chassis, is Major G. W. 1-fayter, 0.B.E., M.I.A.E., to whom, and to Mr. J. Petrie, the general manager of the company, we are indebted for the facilities afforded to us while preparing this article.