Stainless Steel Bodies Reduce Maintenance Costs

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

Con ugated Thin-gauge Sheets Provide Light But Rigid Body Construction and Increased

Pay-load Capacity

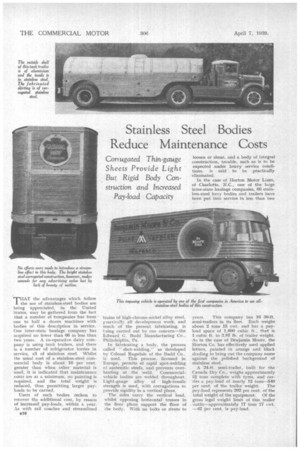

'THAT the advantages which follow 1 the use of stainless-steel bodies are being appreciated, in the United States, may be gathered from the fact that a number of tompanies has from one to half a dozen machines with bodies of this description in service. One inter-state haulage company has acquired no fewer than 66 in less than two years. A co-operative dairy company is using tank trailers, and there is a number of refrigerator lorries in service, all of stainless steel, Whilst the usual cost of a stainless-steel commercial body is about 10 per cent. greater than when other material is used, it is indicated that maintenance co'sts are at a minimum, no painting is required, and the total weight is reduced, thus permitting larger payloads to be carried.

Users of such bodies reckon to recover the additional cost, by reason of increased pay-loads, within a year. As with rail coaches and streamlined

BI6

trains of high-chrome-nickel alloy steel, practically all development work, and much of the present fabricating, is teing carried out by one concern—the Edward C. Budd Manufacturing Co., Philadelphia, Pa.

In fabricating a body, the process called "shot-welding." as developed by Colonel Ragsdale of the Budd Co., is used. This process, licensed in Europe, permits of rapid spot-welding of austenitic steels, and prevents overheating at the weld. Commercialvehicle bodies are welded throughout. Light-gauge alloy of high-tensile strength is used, with corrugations to provide rigidity in a vertical plane.

The sides carry the vertical load, whilst opposing horizontal trusses in the floor plane support the floor of the body. With no bolts or rivets to

loosen or shear, and a body of integral construction, trouble, such as is to he expected .under heavy service conditions, is said to be practically eliminated.

In the case of Horton Motor Lines, of Charlotte, N.C., one of the large inter-state haulage companies, 66 stainless-steel lorry bodies and trailers have been put into service in less than two years. This company has 16 30-ft.

semi-trailers in its fleet. Each weighs about 2 tons 15 cwt. and has a payload space of 1,600 cubic ft., that is 1 cubic ft. to 3,87 lb. of trailer weight Asi in the case of Benjamin Moore, the Horton Co. has effectively used applied letters, painted in orange and black shading to bring out the company name against the polished background of stainless steel.

A .24-ft. semi-trailer, built for the Canada Dry Co., weighs approximately ti tons complete with tyres, and carries a pay-load of nearly 12 tonS-540 per cent, of the trailer weight. The pay-load represents 202 per cent of the total weight of the equipment. Of the gross legal weight limit of this trailer outfit—approximately 17 tons 17 cwt. —67 per cent. is pay-load. There was a saving in licence fees alone of more than 400 dollars in contrast with the fees for previous machines used by this company. The Canada Dry concern has six of these semi-trailers in operation Because of extra pay-load, this company, as in the case of the Horton Lines and others, has been amortizing cost in less than one year from the time each vehicle was put into operation,

An interesting development in tank trailers is a new group being built for the Dairymen's League Co-operative Association (Dairylea) The milk tank, shown in an accompanying illustration, weighs only 4 tons 1 cwt. 1 qr., but has a maximum axle loading of 10 tons. The tank, which holds 3,600 gallons of milk, is of double construction, the outside shell being of aluminium with an inner tank of stainless steel. The corrugated skirt, which is also the chassis, is of stainless steel. Deep bulkheads extend from side to side, both front and rear, to form supports for the tank. Weight is saved by combining the usual skirting and the chassis. Another advantage is the increased beam depth, which increases the rigidity of the structure as compared with a frame of conventional design.