Double Cross on tipper delivery

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

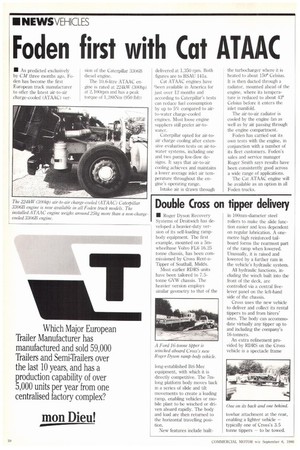

• Roger Dyson Recovery Systems of Droitwich has developed a heavier-duty version of its self-loading rampbody equipment. The first example, mounted on a 5mwheelbase Volvo FL6 16.25 tonne chassis, has been commissioned by Cross Rent-aTipper of Southall, Middx.

Most earlier RDRS units have been tailored to 7.5tonne GVW chassis. The heavier version employs similar geometry to that of the long-established Bri-Mec equipment, with which it is directly competitive. The 7mlong platform body moves back in a series of slide and tilt movements to create a loading ramp, enabling vehicles or mobile plant to be winched or driven aboard rapidly. The body and load are then returned to the horizontal travelling position.

New features include built

in 100mm-diameter steel rollers to make the slide function easier and less dependent on regular lubrication. A onemetre high reinforced tailboard forms the rearmost part of the ramp when lowered. Unusually, it is raised and lowered by a further ram in the vehicle's hydraulic system.

All hydraulic functions, including the winch built into the front of the deck, are controlled via a central fivelever panel on the left-hand side of the chassis.

Cross uses the new vehicle to deliver and collect its rental tippers to and from hirers' sites. The body can accommodate virtually any tipper up to and including the company's 16-tanners.

An extra refinement provided by RDRS on the Cross vehicle is a spectacle frame towbar attachment at the rear, enabling a lighter vehicle — typically one of Cross's 3.5 tonne tippers — to be towed.