New Lynx and Bison from Leyland

Page 46

Page 47

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

ROBUST BUT LIGHT FOURAND SIX-WHEELERS

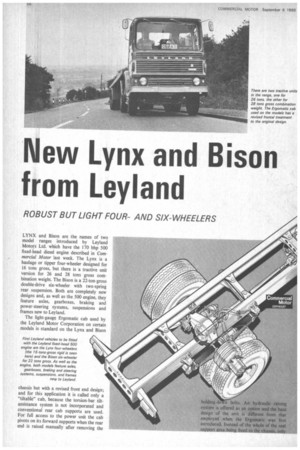

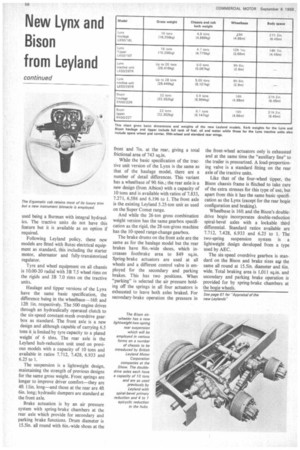

LYNX and Bison are the names of two model ranges introduced by Leyland Motors Ltd. which have the 170 bhp 500 fixed-head diesel engine described in Commercial Motor last week. The Lynx is a haulage or tipper four-wheeler designed for 16 tons gross, but there is a tractive unit version for 26 and 28 tons gross combination weight. The Bison is a 22-ton-gross double-drive six-wheeler with two-spring rear suspension. Both are completely new designs and, as well as the 500 engine, they feature axles, gearboxes, braking and power-steering systems, suspensions and frames new to Leyland.

The light-gauge Ergomatic cab used by the Leyland Motor Corporation on certain models is standard on the Lynx and Bison chassis but with a revised front end design; and for this application it is called only a "tiltable" cab, because the torsion-bar tiltassistance system is not incorporated and conventional rear cab supports are used. For full access to the power unit the cab pivots on its forward supports when the rear end is raised manually after removing the a small area of the cab around the steering column and the pedals stays in position when the cab is tilted, the seat going up with the rest.

Internally, the cab keeps most of its luxury trim but instead of having quickaction lever-drop windows, the glass is raised and lowered manually. The cab is raised 5in. to allow the fan and radiator to be set higher and make for a better approach angle, which is especially important when operating on rough ground. The maximum angle of tilt provided (30deg) is sufficient for the majority of major maintenance work; routine day-to-day checks are provided for by a hinged top to the engine cover, while the radiator is accessible by removing front panels.

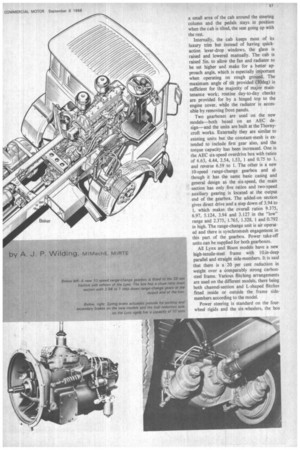

Two gearboxes are used on the new models—both based on an AEC design—and the units are built at the Thornycroft works. Externally they are similar to existing units but the constant-mesh is extended to include first gear also, and the torque capacity has been increased. One is the AEC six-speed overdrive box with ratios of 6.63, 4.44, 2.54, 1.53, 1 and 0.75 to 1. and reverse 6.59 to 1. The other is a new 10-speed range-change gearbox and although it has the same basic casing and general design as the six-speed, the main section has only five ratios and two-speed auxiliary gearing is located at the output end of the gearbox. The added-on section gives direct drive and a step down of 3.94 to 1, which makes the overall ratios 9.375, 6.97, 5.124, 3.94 and 3.127 in the "low" range and 2.375, 1.765, 1.328, 1 and 0.792 in high. The range-change unit is air operated and there is synchromesh engagement in this part of the gearbox. Power take-off units can be supplied for both gearboxes.

All Lynx and Bison models have a new high-tensile-steel frame with 10.in-deep parallel and straight side-members. It is said that there is a 20 per cent reduction in weight over a comparably strong carbonsteel frame. Various flitching arrangements are used on the different models, there being both channel-section and L-shaped flitches fitted inside or outside the frame sidemembers according to the model.

Power steering is standard on the fourwheel rigids and the six-wheelers, the box used being a Burman with integral hydraulics. The tractive units do not have this feature but it is available as an option if required.

Following Leyland policy, these new models are fitted with Butec electrical equipment as standard, this including the starter motor, alternator and fully-transistorized regulator.

Tyre and wheel equipment on all chassis is 10.00-20 radial with 3B 7.5 wheel rims on the rigids and 3B 7.0 rims on the tractive units.

Haulage and tipper versions of the Lynx have the same basic specification, the difference being in the wheelbase-16ft and 12ft lin. respectively. The 500 engine drives through an hydraulically operated clutch to the six-speed constant-mesh overdrive gearbox as standard. The front axle is a new design and although capable of carrying 6.5 tons it.is limited by tyre capacity to a plated weight of 6 tons. The rear axle is the Leyland hub-reduction unit used on previous models with a capacity of 10 tons and available in ratios 7.712, 7.428, 6.933 and 6.25 to 1.

The suspension is a lightweight design, maintaining the strength of previous designs for the same gross weight. Front springs are longer to improve driver comfort-they are 4ft 1 lin. long-and those at the rear are 4ft 6in. long; hydraulic dampers are standard at the front axle.

Brake actuation is by an air pressure system with spring-brake chambers at the rear axle which provide for secondary and parking brake functions. Drum diameter is 15.5in. all round with 6in.-wide shoes at the front and 7in. at the rear, giving a total frictional area of 743 sq.in.

While the basic specification of the tractive unit version of the Lynx is the same as that of the haulage model, there are a number of detail differences. This variant has a wheelbase of 911 6in.; the rear axle is a new design (from Albion) with a capacity of 10 tons and is available with ratios of 7.833, 1.271, 6.586 and 6.196 to I. The front axle is the existing Leyland 5.25-ton unit as used on the Super Comet range.

And while the 26-ton gross combination weight version has the same gearbox specification as the rigid, the 28-ton-gross machine has the 10-speed range-change gearbox.

The brake drums on the front axle are the same as for the haulage model but the rear brakes have 8in.-wide shoes, which increases footbrake area to 849 sq.in. Spring-brake actuators are used at all wheels and a different control valve is employed for the secondary and parking brakes. This has two positions. When "parking" is selected the air pressure holding off the springs in all four actuators is exhausted to leave both axles braked. For secondary-brake operation the pressure in the front-wheel actuators only is exhausted and at the same time the "auxiliary line" to the trailer is pressurized. A load-proportioning valve is a standard fitting on the rear axle of the tractive units.

Like that of the four-wheel tipper, the Bison chassis frame is flitched to take care of the extra stresses for this type of use, but apart from this it has the same basic specification as the Lynx (except for the rear bogie configuration and braking).

Wheelbase is 16ft and the Bison's doubledrive bogie incorporates double-reduction spiral-bevel axles with a lockable third differential. Standard ratios available are 7.712, 7.428, 6.933 and 6.25 to 1. The two-spring suspension system is a lightweight design developed from a type used by AEC.

The six-speed overdrive gearbox is standard on the Bison and brake sizes ate the same all round at 15.5in. diameter and 6in. wide. Total braking area is 1,011 sq.in. and secondary and parking brake operation is provided for by spring-brake chambers at the bogie wheels.

See page 61 for 'Appraisal of the new Leylands"