WASTE NOT WANT NOT

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

If you want to be taken seriously in the recycling market, you need a credible infrastructure. Tim Maughan reports on three operators, with highly specialist pieces of machinery.

MOTWARD TIMBER RECYCLING

Recycling is a growing sector, and the potential for road transport operators is enormous. Some hauliers may occasionally transport consignments for this market; others transport recycleable goods on a regular basis.A third type haul the goods, hut also invest in the infrastructure which enables them to field their own recycling operations.

Motward limber Recycling is one such firm. It runs three tractive units, a rigid, four walking-floor trailers and three bulk tippers. There is also a transport arm, Motward, which runs three units and six curtainsiders.

The company depot is located metres from the southbound carriageway of the Al, near Sandy, Beds. We drive into their yard, and the first things we see are pallets —a lot of them.

JasonTolhurst, MD, and general manager Ian Kennington explain that the firm is a specialist pallet recycler. But how times have changed. Years ago, there used to be a bonfire burning away on these premises. 24 hours a dayAged pallets were dropped at the site, and incinerated.

These days, such a fiery process seems unthinkable. And fresh timber is no longer used to make pallets. Instead, says Kennington, they are fashioned from fragments of old pallets, and recycled wood.

Pallet repairers

We are handling thousands of pallets a week," says Tolhurst. When pallets arrive at the Sandy depot, their fate is sealed. With a practised eye,Tolhurst and a team of three sorters can judge if a pallet is fit for repair, or is destined for the chipper. He employs seven full-time pallet repairers, who give battered pallets anew lease of life before they reenter Britain's transport chain. Some 7,000 pallets are requisitioned every week.

• 1•1101r,PINI

The Sandy site has the feeling of a specialist cottage industry about it. But things are very different 20 miles north, at an old RAF base. Aleonbury Airfiekl.The jets of the United States Air Force have left this site.There is residential accommodation for USAF personnel here, but its spacious runway and taxiing areas now serve as an industrial estate.

Tolhurst has set up his shredding facility in a hardened hangar. formerly used to house Phantom jets. This must be one of the most unusual, and secure, road transport sites ever used. It has a relatively low profile, a caverned roof, and each main door (there are two) weighs a colossal 70 tonnes.

Moreover, it was built to be nuclear, chemical, and biological agent proofThere is a hefty side entrance door, complete with a turning wheel, which is akin to something you might expect to find in a submarine.The building gives a whole new meaning to the term "site security". Within it lavsTolhurst's pride and joy: a £300,000 shredder, made by German firm Vecoplan.There is also a trio of forklifts, and a Manitou tele handler.There are 14 men employed at this site.

Woodchip for furniture

Customers pay Motward a fee for tipping their unwanted pallets..Tolhurst also buys them from agricultural producers, for between 50p and £1 a time. If they are not repaired in Sandy, they are munched by the mighty Vecoplan and out pops the woodchip.

"The woodchip is used in furniture. We deliver it as far north as Hexbam, and across southern England. All the woodchip is carried in walking floor trailers," says Tolh urst.

The shredder, says works manager John Boddington. can process seven tonnes of wood an hour. Powerful magnets relieve them of nails, 12 tonnes of which are collected a month.

The gear is expensive, butTolhurst maintains he can't do without it.-We must have the machinery. If we did not, it would mean that we would have to use another party,and there would be too much transport involved."

The government offers no financial support to the firm.That said, it inadvertently assists it with ever-increasing landfill taxes.The tax currently stands at £18 per tonne, and is set to increase by at least £2 every year.

"It's cheaper for people to pay for us to take pallets than to send them away in a skip, and to landfill," remarks Kennington.

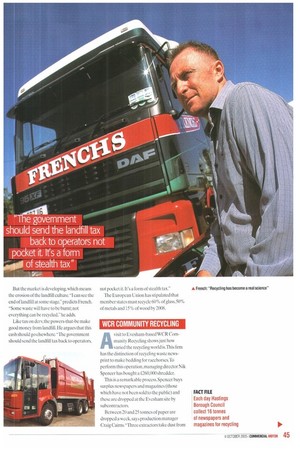

FRENCH'S SKIP & GRAB HIRE

Dave French, managing director of French's Skip and Grab Hire. expresses the same views. His St-Leonards-onSea-based company fields 24 trucks. The fleet includes artics, eight wheeler roll on/roll offs, tippers and skip trucks. French has a pool of 2,000 skips of various shapes and sizes.

Local authorities must promote recycling, and ensure that quotas are met. High landfill taxes serve to deter the depositing of waste into the ground. Both these factors account for the recycling boom. "It is really beginning to bite now," says French.

But he thinks there is a long way to gal really think you have to follow the Continental lead.There are three types of waste landfill, second use/salvage, and recycling. I believe the way forward is a combination of recycling, and energy from waste, where it is burnt.

-This is big in France, because they have no oil, and little coal.'The Continental Europeans are 40 years ahead of us in recycling."

The UK has a lot of catching up to do, but it is making progress.Hastings Borough Council collects household waste and drops it at the French depot. Homeowners separate cardboard, paper, plastics and metal products before collection.

Like Motward limber and Recyling, French has built up an impressive infrastructure to enable him to flourish in his chosen market.

-We have always worked with Hastings Borough Council," he says. "They approached me to do recycling work in 1999.1t grew from being an experiment to one of the busiest doorstep collections in the country."

His base acts as a consolidation hub. Every day, the council brings in 16 tonnes of newspapers and magazines. It is reloaded onto French HGVs and taken to a paper mill.

Huge investments

He has invested £250,000 in two sheds: one to accommodate the paper, the other to house the council's £450,000 edicurrent separator.This machine is not yet in place, but we see the plans.

When installed, it will separate plastics, metals, and other household waste. It also plucks aluminium from the refuse. French is paid per load mile, a rate he describes as "fair".

Recycling products have economic value. Councils, French says, seek to make money by selling waste on. Hastings Borough Council is stumping up the cash for the apparatus.Because transport is so integral to the process, it makes sense to locate it within French's base.

An agreement like this is reciprocal. French has shown his commitment by building the sheds and, in return, the council keeps his fleet busy, "Recycling has become a real science and, like any science, it keeps on moving.Ten years ago, recycling was seen like scrap metal in this country it was not a huge thing." But the market is developing, which means the erosion of the landfill culture."I can see the end of landfill at some stage." predicts French. "Some waste will have to be burnt; not everything can be recycled,he adds.

Like tax on derv. the powers-that-be make good money from landfill. He argues that this cash should go elsewhere. -The government should send the landfill tax back to operators, not pocket it. It's a form of stealth tax."

The European Union has stipulated that member states must recycle 60% of glass,50% of metals and 15% of wood by 2008.

WCR COMMUNITY RECYCLING

Avisit to Evesham-based WCR Community Recycling shows just how varied the recycling world is.This firm has the distinction of recycling waste newsprint to make bedding for racehorses. To perform this operation, managing director Nik Spencer has bought a £260,000 shredder.

This is a remarkable process. Spencer buys surplus newspapers and magazines (those which have not been sold to the public) and these are dropped at the Evesham site by subcontractors.

Between 20 and 25 tonnes of paper are dropped a week, says production manager Craig Cairns. "Three extractors take dust from the paper. Racehorses cannot take in dust."

WCR use a 7.5 tonner to deliver bedding to stables; the vehicle can carry 150 bales.The firm also uses the services of subcontractors. Each bale sells for f4 (ex-VAT).

There are seasonal peaks and troughs. reports Cairns. Summer and early autumn are quiet times and the pace picks up in November, with the busy period lasting until the following May.

The Hunting with Dogs ban has impacted on WCR. It used to drop bedding to six hunts, but not anymore.

However, there is still demand from the racehorse stables, and even pig farmers, who require bedding.

WCR runs a diverse,even circular operation,which highlights the wealth or recycling possibilities.

Having delivered the bedding to stables it returns with manure that it has collected from them to be turned into fuel for power stations.

"We send an eight-wheeler, with a grab, to the stables, or we use a subcontractor,"saysSpencer."After the manure is taken away.it is blended with chicken manure, and burnt in power stations. We transport between 500 and 600 tonnes of it a week."

Because the chicken droppings contain a lot of nitrogen, they burn very nicely.

Delicate chests

Like French. Spencer has also chosen to involve himself in the municipal world.WCR collects paper from homes in the areas covered by Herefordshire Council and Solihull Metropolitan Borough Council.

This paper cannot be used for bedding, because it has been touched by human hands. and this could upset the racehorses delicate chests. Instead, it is used for conventional paper recycling.

There is also a hire side to the business. WCR Vehicle Hire provides 100 refuse and recycling vehicles to local authorities.As a group, the company turns over £4m.

There are opportunities to be seized in recycling, says sales director Matt Gibbon. "There will he different collection methods. At the end of the day something has to be done with waste."

But is it competitive? "Very.A lot of people think that it is an easy industry to get into, and that it's easy to make money. But it is very different.You need to have an understanding of the whole process. And there is the price of the vehicles; there is no point incurring ,000 overheads and getting a £950 fee."

Unlike private f irms, councils use residents' cash, so want top quality service.Tendering processes are thorough.

"Local authorities have recycling targets, no matter where you live.To succeed, you must understand the market and stand by the rate you put in.And you also need to understand vehicle costings."

Top-loaders, along with so many moving electrical and hydraulic parts, are prone to high servicing and repair costs, he says.

By its very definition, recycling is an endless market, And, like French, Gibbon is adamant that landfill has had its day. "We are running out of holes," he asserts. •