RUNNING, UPKEEP AND OVERHAUL.

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

Interesting Contributions from Maintenance Engineers, Drivers and Mechanic3.

A Quickly Detachable Tipping Body.

FROM Featherstone, Yorkshire, we have received .a letter by " J,B.," who tells how his firm has had a tipping body made which can very easily be removed at week-ends to permit a 14seater bus body to be fitted in its place.

He points out that, as usually constructed, tipping bodies have their separate fittings secured independently to the.chassis frame. This necessitates the removal of a number of bolts and the replacing of a number of parts which have to be. readjusted to work in unison.

The plan he has found so successful is to provide two stout planks, so arranged that by simple hooks they call be attached to or detached from the frame by removing four nuts only. To the upper side of these planks he attached all parts belonging to the tipping apparatus.

We do not envy the passengers who ride in the bus at week-ends, as the springs usually fitted to tipping wagonS are not often suitable for passenger carrying.

Trouble with the Springs of a Trailer.

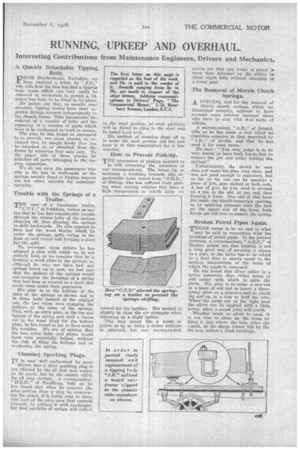

THE user of a Carrimore trailer, " C.T.Y.," of Peckham, writes es saying that he has had considerable trouble through the centre bolts of the springs shearing off, thus allowing the springs to shift backwards. He also appears to have had the wood blocks, which lie under the springs, split, owing to the head of each centre bolt forming a start for the split.

To overcome these defects he has adopted a plan with which we do not entirely hold, as we consider that he is forming a weak place in the springs, so, although he may not have had any springs break up to now, we feel sure that the makers of the springs would not recognize thebreakage of a spring that had been so treated as a fault that could come under their guarantee. His plan is to file hollows at the sides of the springs as shown and to fit three bolts instead of the original one, the two extra ones engaging the hollows at the sides of the springs. This, with an extra plate at the top and bottom of the spring and with a recess cut in the wood block for the bottom plate, he has found so far to have ended his troubles. We are of opinion that the two extra bolts and plates would have very materially helped, without the risk of filing the hollows and so weakening the spring.

.Cleaning ,Sparking Plugs.

IT is now well understood by most drivers that a dirty sparking plug is not affected by the oil that may collect on its parts, but by the carbon which the oil may contain. A correspondent, " EI.R.11.," of Swaffham, tells us he has found that when he removes the mica portion from a plug by unscrewing the gland, it is fairly easy to clean ihat part of the m-ica cone that extends inwards, by rubbing it with sandpaper, but that particles of carbon will collect

in the steel portion, as such particlea will be found to cling to the steel and be baked hard to it.

His method of cleaning them off is to make the steel portion red hot and keep it at that temperature for a few minutes.

How to Prevent Pinking.

TDB prevention of pinking appears to be still attracting the attention of our correspondents. The latest tip to minimize a tendency towards this objectionable noise comes from " of Sidcup, who has suffered from pinking when driving vehicles that have a high compression or which have Po

control for the ignition. His method is slightly to close the air strangler when labouring -up a slight incline.

This may sound like a waste of petrol, as by so doing a richer mixture is obtained, but our correspondent points out that any waste of petrol is more than balanced by the ability to climb slight hills without changing to a lower gear.

The Removal of Morris Clutch Springs. _

SPECIAL tool for the removal of Morris clutch springs, which we illustrated recently, appears to have aroused . some interest amongst those who have to deal with that make cf vehicle.

A correspondent, " A.B.;" of Bristol, tells us he has made a tool which he considers superior to that described by "JAC.," of Bootle, and that he has used it for some years.

He says: " You may judge it to be very handy to have both hands free to remove the pin and collar holding the springs."

• Unfortunately, the sketch he sent does not make his plan very clear, and was not good enough to reproduce, but as far as we can see he employs a piece of i-in, pipe slotted at both ends. A bar of I-in. by +-in, steel is pivoted on a pin in the slot at one end, thus forming a lever. One end of this lever fits insida the clutch-inspection opening, so by applying pressure with the foot on the upper end of the lever, both hands are left free to remove the spring.

Broken Petrol Pipes Again.

THERE seems to be no end to what

may be said in connection with the breakage of petrol pipes. In the present instance, a correspondent, " A.R.P.," of Honey, points out that brazing is not a very good way of securing a nippie to a pipe, as the latter has to be raised to a heat that is nearly equal to the meltiogtemperature of the brass of which the nipple is composed.

He has found that silver solder is a better substance than either brass cc soft solder with which to unite the parts. His plan is to make a saw-cut in a piece of rod and to insert a threepenny piece or a sixpence and to pinch the rod up in a vice to hold the coin. When the parts are at the right heat the silver can be applied with a little borax, when a sound joint will result.

Whether brass or silver be used, it is not wise to clean up the braze by filing it just where the tube joins the nipple, as the sharp corner left by the file may induce a fresh breakage.