MAKING BEST USE OF THE FORD.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, which will Appeal to the Owner, Driver, and Repairer.

IN THIS series of hints concerning the Ford light chassis and ton truck wherever they are employed for commercial purposes, we endeavour to deal with the subject from every Niew-point, so that the advice given will appeal to the owner, driver, maintenance engineer, or mechanic. Valuable sources of information are being tapped for this purpose, and it should be understood that the advice given will be derived from those with an intimate knowledge of •the subject.

We shall welcome for inclusion among the hints those which have proved of value to individual users, and will make suitable remuneration for any published. What we desire are the results of practice.

128.—If the Switch Key be Lost.

Many drivers appear to think that if they lose their switch key they will have to stop until they can obtaintanother. As a matter of fact, the keys are of very simple construction, and a small screwdriver, or the screwdriver end of a pair of pliers, will serve just as wellwuntil another key be procured.

129.—Refacing Scored or Worn Commutator

Uneven wear of the track of a commntator, whether it be of the brush, roller or other type, causes the rotor to jump and, consequently, the engine misses badly, especially at high speeds.

For Blue Blaze and other commutators resembling this type, take a bolt about 4 ins. long threaded for a considerable part of its length, and of a diameter small enough for the shank to be held in the chuck of a brace or breast drill after the head has been cut off.

Now obtain a piece of three-ply wood and cut it to a circular shape so that it is a free fit in the timer body. To this piece of wood glue a strip of fine emery cloth on one aide only, and bore a central hole to take the bolt. Run one nut on to the bolt, then the wood wheel faced with emery, and lock the wheel in position by means of a second nut. Carefully hold the commutator in a vice and use the emery " bob " for truing the track, in the same way as one would grind a valve, frequently removing it from the surface and shaking off the ground particles DO that these do not form scores in the surface.

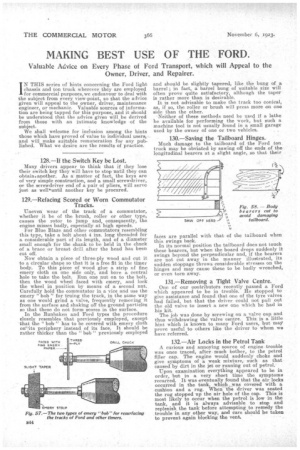

In the Runbaken and Ford types the procedure closely resembles that previously employed, except that the " bob " has to be covered with emery cloth on'its periphery instead of its face. It should be rather thicker than the " bob " previously employed 57.—The two types of emery "bob" for resurfacing the tracks of Ford and other timers.

544 and should be slightly tapered, like the bung of a barrel ; in fact, a barrel bung of suitable size will often prove quite satisfactory, although the taper is rather more than is desirable.

It is not advisable to make the track too conical, as, if so„ the roller or brush will press more on one side than the other.

Neither of these methods need be used if a lathe be available for performing the work, but such a machine tool is not usually found in a small garage used by the owner of one or two vehicles.

130.—Saving the Tailboard Hinges.

Much damage to the tailboard of the Ford ton truck may be obviated by sawing off the ends of the longitudinal bearers at a slight angle, so that their faces are parallel with that. of the tailboard when this swings back. In its normal position the tailboard does not touch these bearers, but when the board drops suddenly it swings beyond the perpendicular and, if the bearers are not cut away in the manner illustrated, its sudden stoppage throws considerable stresses on the hinges and may cause these to be badly wrenched, or even torn away.

131.—Removing a Tight Valve Centre.

One of our contributors recently passed a Ford which appeared to be in trouble. He stopped to, give assistance and found. that one of the tyre valves had failed, but that the driver could not pull out the old valve to insert a new one which he had in his kit.

The job was done by screwing on a valve cap and thus withdrawing the valve centre. This is a little hint which is known to many Ford users, but may prove useful to others like the driver to whom we have referred.

132.—Air Locks in the Petrol Tank

A curious and annoying source of engine trouble was once traced, after .much bother, to the petrol filler cap. The engine would suddenly choke and give symptoms of a weak mixture,such as that caused by dirt in the jet or running out of petrol. Upon examination everything appeared to be in order, but in a very short time the symptoms recurred. It .was eventually found that the air locks occurred in the tank, which ,was covered with a cushion and a rug. When the 'driver was seated the rug stopped up the air hole of the cap. This is most likely to occur when the petrol is low in the tank, and it is always advisable to step and replenish. the tank before attempting to remedy the • trouble in any other way, and care should be taken to prevent again blocking the vent.