Electric Vehicle Maintenance

Page 10

Page 11

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

Made Easy

By L. J. COTTON, M.I.R.T.E.

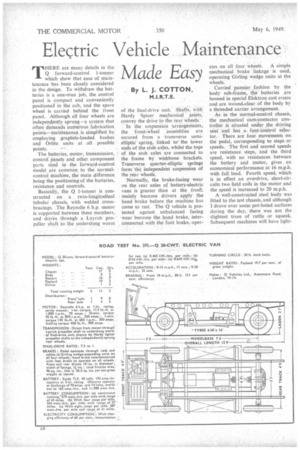

THERE are many details in the Q forward-control 1-tonner which show that ease of maintenance has been closely considered in the design. To withdraw the batteries is a one-man job, the control panel is compact and conveniently positioned in the cab, and the spare wheel is carried behind the front panel. Although all four wheels are independently sprung—a system that often demands numerous lubrication points—maititenance is simplified by employing graphite-loaded bushes and Orlite units at all possible

points. .

The batteries, motor, transmission, control panels and other component parts Used in the forward-control model are common to the normalcontrol machine, the main difference being the positioning of the batteries, resistance and controls.

Basically, the Q 1-tonner is constructed on a twin-longitudinal tubular chassis, with welded crossbracings. The Reyrolle 6 h.p. motor is supported between these members, and drives through a Layrub propeller shaft to the underslung worm

of the final-drive unit. Shafts, with Hardy Spicer mechanical, joints, convey the drive to the.rear wheels.

In the suspension 'arrangements,, the -front-wheel . assemblies are secured from a transverse semiellipticspring, linked to the lower ends of the stub axles, whilst the tops of the stub' axles are connected to the frame by wishbone brackets. Transverse quarter-elliptic springs form the independent suspension of the rear wheels.

Normally, the brake-facing wear on the rear axles of battery-electric vans is greater than at the fron't, mainly because drivers apply the hand brake before the machine has come to rest. The Q vehicle is protected against unbalanced facing wear because the hand brake, inter connected with the foot brake, oper. ates on all four wheels. A simple mechanical brake linkage is used, operating Girling wedge units at the wheels.

Carried pannier fashion by the body sub-frame, the batteries are housed in special Elektron cast crates and are wound.clear of the body by a threaded carrier arrangement.

As in the normal-control chassis, the mechanical cam-contactor controller is situated under the driving seat and has a foot control selector.. There are four movements on the pedal, corresponding to steps or speeds. The first and second speeds are resistance steps, and the third speed, with no resistances between the battery and motor, gives an economical performance at 16 m.p.h. with full load. Fourth speed, which is in effect an overdrive, short-circuits two field coils in the motor and the speed is increased to 20 mph.

A well-constructed steel body was fitted to the test chassis, and although I drove over some pot-holed surfaces during the day, there was not the slightest trace of rattle or squeak. Subsequent machines will have light

alloy bodies. The cab is planned with ample space for the driver, and the relatively wide cab doors, fitted forward of the front axle, give easy access to the driving seat.

Specific-gravity readings of the electrolyte, taken before leaving the Fulham depot, gave average results of 1.280 per cell. With a representative 101-cwt. payload of iron castings and carboys on board, I started the continuous run.

With the 20 m.p.h. maximum speed of the machine, I was able to keep pace with other traffic through Hammersmith and along the Chiswick High Road, until meeting the dual carriageway of the Great West Road. Fortunately, there had been only two slight traffic delays up to this point to spoil the continuity of the trial. • I drove precisely 17 miles in the first hour, a reasonable average speed, as the first few miles were covered in

heavy traffic. A check on the performance at the -end of the hour showed the speed on level ground to be 20 m.p.h., balancing current 60 amps. and 77 volts, and a meter reading of 65 amp.h rs.

After two hours the gpeed and balancing current had remained unchanged, and the total mileage had risen to 35. At this point 1 steered a course towards Fulham, and six miles later the state of discharge of the batteries was apparent by the loss of speed on inclines. By the time the depot was reached, 4243 miles from the start, the speed on the level was down to 15 m.p.h. The time taken for this test was 2 hrs. 20 mins. Although the voltage, while running, had fallen to 60, the electrolyte gravity readings of 1,160-1.165 showed that the batteries were not fully exhausted.

A fitter removed the side panels, wound out the batteries and fitted replacement fully charged units within 10 mins. With no floor traps to the body, the batteries are normally wound clear of the body for inspection or maintenance.

Before making the delivery trials, a call was made at the Kensington weighbridge to check the laden, unladen and distributed weights. The front axle carried a slightly greater proportion of the load than the rear axle. The effect of this could not be felt on the steering, which was lighter than that of the normal-control model tested last year.

Local Delivery Conditions The two trials of four and eight stops per mile were made over a course in the South Kensington area, which *as reasonably level and with a turn at every mile. Repeat tests were made to cheek the results, and calculated from the discharge over a given distance showed that the vehicle had a potential range of 37 miles with four stops per mile, and 31 miles with halts at about every 200 yds. There was no trace of brake bind, and the tractive effort was 25 lb, per ton when measured at 20 m.p.h.

Acceleration and braking were reasonable. From rest, 15 m.p.h. was reached in 15 secs. With an emergency application of the brakes the vehicle was brought to rest in 20 ft. from 18 mph. The test chassis had little mileage showing on the mileometer, so that both acceleration and braking would probably be improved within a few hundred miles, when highspots would have been removed from the bearing surfaces.

The steepest incline in the area, at Campden Hill Square, was climbed without difficulty, with a minimum speed of 5-6 m.p.h. Battery dis charge, measured when moving away on the 1 in 7.5 incline, was 320 amps. at 65 volts.

There was no question whether the brakes would hold the vehicle on a steep incline, but to vary the con

ditions of the trial the main control lever was shifted to the reverse position, first speed engaged, and the van slowed down to a halt on a reversal of power. Although this is not recommended as a standard practice, it does prove that the Q vehicle can be stopped in the event of a brake failure. , During the day's trials I found the test vehicle pleasant to drive, especi-.. ally during acceleration. The control arrangement provides continuous acceleration without snatch or judder as the " speeds " are engaged. The relatively high driving seat, coupled with the one-piece full-width windscreen, affords the requisite visibility for congested areas, and the 30-ft. turning circle gives a high degree of manceuvrability. Traffic indicators are standard fittings.