HINTS ON MAINTENANCE.

Page 32

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

516.—Improving the Big-ends on a Vulcan.

One of our readers who is in charge of a fleet of 30-cwt. Vulcan lorries has had a certain amount of trouble with the big-ends.

The design of the big-ends makes it essential to have packing-pieces between the halves of the con nectmg rod, and the maker's packing-pieces do not overlap the bearing itself. The result is that., after a short period of use, all the stress is taken by the +-in, spigot and sometimes the spigot hole in the bearing wears to a serious degree, so that the brasses shift to such an extent that the oil holes are blocked, with the result that the bearings run out. The method of overcoming the difficulty was a very simple one. It consisted of fitting wide steel shims which project over the edges of the brasses and, consequently, prevent these from moving. Since following this procedure no further trouble has been experienced.

517.—Preventing the Oil-relief Valve on the Tylor Engine from Sticking.

Cases of failure in the oil pressure on Tylor engines sometimes occur awing to small particles of carbon, dirt, etc., laeing pumped round with the oil and finally lodging on the seating of the oij relief valve, thus preventing the ball from closing in the proper manner and resulting in seizure and running out of the white metal of the big-ends if not observed in Lime.

After this had occurred several times to the engine used by one of our contributors he overcame the trouble by soldering a piece of fle gauze over the mouth of the oil-relief valve, this gauze being kept clean by the force of oil to the outside filter.

518.—Repairing a Feed-water Heater.

The driver of a steam wagon reported to the head mechanic of a certain repair shop that he had great difficulty in maintaining steam on his vehicle. He also stated that the pump would not feed the boiler at its normal rate.

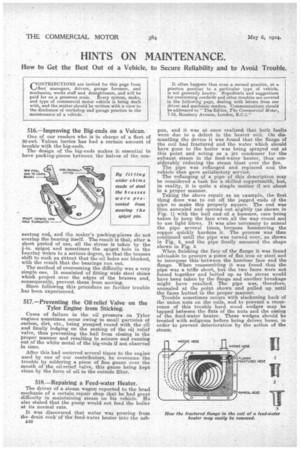

It was discovered that water was pouring from the drain cock of the feed-water heater into the ash£46 pan, and it was at once realized that both faults were due to a defect in the heater coil. On dismantling the device it was found that the flange of the coil had fractured and the water which should have gone to the boiler was being sprayed out at this point and acting as a jet condenser for the exhaust steam in the feed-water heater, thus considerably reducing the steam blast over the fire. The pipe was reflanged and replaced and the vehicle then gave satisfactory service. The reflangmg el a pipe of this description may be considered a task for a skilled coppersmith, but, in reality, it is quite a simple matter if set about in a proper manner. Taking the above repair as an example, the first thing done was to cut off the jagged ends of the pipe to make this properly square. The end was then annealed and opened out slightly (as shown in Fig. 1) with the ball end of a hammer, care being taken to keep the face even all the way .round and to use light blows. It was also necessary to anneal the pipe several times, because hammering the i

copper quickly hardens t. The process was then continued until the pipe was turned over, as shown in Fig. 2, and the pipe finally assumed the shape shown in Fig. 3.

When finishing the face of the flange it was found advisable to procure a piece of flat iron or steel and to interpose this.between the haminer face and the flange. When reassembling it was found that the pipe was a trifle short,, but the two faces were not forced together and bolted up as the stress would have been taken by the flange and another breakage might have resulted. The pipe was, therefore, annealed at the point shown and pulled up until the faces butted in the proper manner. Trouble sometimes occurs with slackening back of the union nuts on the coils, and to prevent a recurrence of this trouble hard wood wedges may be tapped between the flats of the nuts and the casing Of the feed-water heater. These wedges should be treated with solignum before being driven home, in order to prevent deterioration by the action of the steam.