THE OVERHAULING OF A COMMERCIAL VEHICLE.

Page 20

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

Useful General Hints to Secure Economical and Efficient Work. The Rectification of Bearings, Keyways, etc.

THE QUESTION has lately been asked, "Does it pay to overhaul ? " The answer to this, from the economical point of view, is, "Yes, if properly done." There may be cases where an already weil-worn vehicle has been picked -up at a break-up price and has reached the stage where a decision is called for ; then, in some such cases, it may pay to buy another vehirele rather than to renew all the parts necessary to make a thorough job of the overhaul.

If an overhaul is undertaken it is well to carry it out properly, as one badly worn part may very often cause damage to other parts. The idea that overhauling does not pay is generally found to have been created in the mind of a person who has run a vehicle too long without reasonable attention, with the result that there is hardly a sound part in the whole affair.

In considering the subject, the cost of the overhaul must be reckoned with. Many overhauls cost far more than they should, because they are not carried out under suitable conditions and with due care. Often some unit has to be taken to pieces after assembling, simply through carelessness in not marking some component part to show where it should have gone. In some cases, a washer or distance piece has been left out, and the whole thing has to be taken down for this reason. We will try, so far as possible, to point out how time and expense can be saved in overhauling and reconditioning.

Make a Fair Start, Whether the job, consists of a whole chassis or a unit such as an engine, or gearbox, it is best to see that a clear bench is ready to receive the parts when cleaned cif. It is not unusual to see the parts of a job undergoing repair placed on a bench already littered with theJ iebris and scrap resulting from MN ny previous jobs of the kind, There is noineed for the filthy state in which one usually finds. the repair bench. We have known men who have carried out repairs for years and have always been able to keep benches as clean asif new work was going-on instead of repair work.

Taking down either a unit or a. whole chassis is necessarily a, dirty job, but the dirt can be confined to one spot and can he cleared up when the job is Finished. There is no need for the parts taken out to be »laced on the benehes»intil they are cleaned. We may seem to be harping too much on he point of cleanliness, but we have found that dirty condiu36 tions in a repair shop encourage a general careless and slovenly state of affairs, which does not tend towards efficiency.

A tool-box somewhat similar to that used by a farrier, a-1 shown in Fig. 1, is a useful adjunct to the repairer. It is better to take this to the place where the chassis is being worked on and to put each tool back in the box instead of throwing it on the floor. Boxes should be provided for the reception of all bolts, nuts and other small parts. The bulk of the oil should be drained off from gearbox, engine and differential, so as to make as little mess as possible. Frequently these parts can be dismantled when removed from the chassis on' trestles or some temporary support, so as to keep the work-bench clean.

When each unit has been removed and taken to pieces and its components put. into separate boxes, all is ready for cleaning. Great care should be taken while dismantling to see that any part which might be replaced wrongly should be marked. If a set. of number runchea is not available, marks can be made with a centrepunch or chisel, which will indicate the position of the part when ready for reassembly.

Cleaning of Dismantled Parts.

A great deal of time and money can be 'saved by a more scientific method of cleaning dismantled parts. Here, again, there is no need for the horrible mess one sees in many repair shops, or the waste of rags in cleaning. Wiping with rags can be entirely avoided. Messrs. Mann, Egerton and Co., Ltd., make very useful cleaning tank which will soon repay for intallation. There are, however, many works 'where such an outfit will not, be found, and the following directions, if carried out, will be found to answei very well.

All parts taken from the inside of engines, gearboxes, etc.• should be washed in a bath of paraffin, using a stiff brush to loosen the greasecor thick oil. When the internals have, been washed, the outer cases should be scraped so as to remove all caked mud and washed in the same bath. It is not necessary to clean then. but only to loosen the grease. After this they .should be laid on the ground in a, yard and played on with a hose from a tap. The greater the pressure of water, the sooner the grease will disappear. The pipe should have a small nozzle or be pinched.together with the fingers so as to contract it and make a small high-pressure jet of the water. The watee will be found to drive all the loosened grease before it and will penetrate all holes and recesses. Not a pennyworth of rag need be used, and the parts will be far cleaner than any amount of wiping with rags will ever make them. A shake will free them from any water which may be adhering, and they can then be laid on the bench without in any way dirtying it.

Ball or roller bearings are best cleaned in a second or third bath of paraffin and, if any water has got to them, they should be placed in a warm place so that'it, can evaporate.

Care should be taken .to make sure that no small part such as a key or thin washer is. thrown away with the dirty paraffin.

The Examination of All Parts.

All parts should now be carefully examined for defects. The teeth of all gears should be scrutinized separately. Cracks and surface abrasions should be looked for. All-bearings, such as those of the bigcads, should be examined to see whether they are fit for further service by merely letting them together, but, before deciding on this point, it is well to make sure that the white metal is not separating, hem the bronze. This can easily be done by ringing them. If they sound like a cracked gong the metals are coining apart and the bronzes should be remetalled. It is useless trying to fit new bearings to journals which are not, round, so all journals such as those of crankshafts should be examined with a micrometer. Callipers will do if no micrometer be at hand, but they are difficult to use and will not show minute defects so well..

In reassembling, the question as to whether a ball bearing is fit for further service is a matter of judgment, and no hard and fast rules can be given. All such bearings should be carefully examined, and, if there is too much side play, it is a sign -that wear has taken place. If it is decided that this is not sufficient to condemn the bearing. it. is well to examine for abrasion of the ball tracks. This can mostly be done by spinning the bearing when dean and free from thick oil. If, when spinning, there is a noise and a feeling that the balls are passing over surfaces which are not smooth, it. is useless to replace the bearing. There are many firms who regrind the ball tracks and fit a new set of balls at a moderate cost. In many cases this is found to be an economical plan, 'but is not recommended in the case of •bearings which have very heavy work to do.

The next most difficult point in connection with ball bearings is to examine them to see that they are not loose fits in their housings or on the shafts. The fit in the housing is probably the must important, as, in many cases, they are not clamped in any way, but simply rely on their being a good. fit to prevent them from turning round in the housing. Should it be found that there is perceptible shake when the bearing is in its housing, something must be done to remedy this. There are many ways of accomplishing this, such as the depositing of metal by electricity, etc. Many of these are quite outside the possibilities of an ordinary workshop, so we propose to suggest only simple means. Among these, perhaps,

Fig. 3.—In ball bearings having no filling slot, the cage most be correctly replaced or the balls will fall as Indicated.

the simplest is the introduction of a thin steel ribbon, a few thousandths of an inch thick, between the bearing and its housing. This hard steel ribbon can be bought for the purpose from Messrs. Smith and Sons, St. John's Square, Clerkenwell, London, E.C. It is sold in strips, 4 ins, wide by 3, 4, or 5-thousandths of an inch thick.

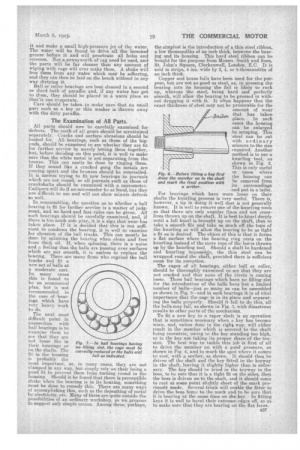

Copper and brass foils have been used for the purpose, but are not so good as steel,. as, in pressing the bearing into its housing the foil is likely to ruck up, whereas the steel, being hard and perfectly smooth, will allow the bearing to be pressed in without dragging it with it. It often happens that the exact. thickness of steel may not be procurable for the amount of wear that has taken place. In such cases the housing can be enlarged by scraping. This 'steel can be cut 'with ordinary scissors to the size required. Another method is to use a knurling tool, as shown in Fig. 2. This is only useful in cases where the housing can be removed from its surroundings and put in a lathe.

For bearings which have worn loose on their shafts the knurling process is very useful. There is, however, a tip in doing it well that is not ;generally known. It is well to remove one of the knurling tools so that there are only angular lines and not crosslines thrown up on the shaft. It is best to knurl deeply until a full knurl is brought up on the shaft, then to take a smooth file and take as much off the tops of the knurling as will alluw the hearing to be as tight a fit as is desired. The object of this is that it forms a flat surface where the bearing ring rests on the knurling instead of the mere tops of the burrs thrown up by the knurling tool. Should a shaft be hardened and knurling impossible, the thin steel can be wrapped round the shift, provided there is sufficient room for its reception.

The cages of all bearings, either ball or roller, should be thoroughly examined to see that they are not cracked and that none of the rivets is coming loose. Those ball bearings which have no filling slot for the introduction of the balls have but a limited number of halls—just su ;many, as can be assembled as shown in Fig. 3—and in such bearings it is of vital importance that the cage is in its place and separating the balls properly. Should it fail to do this, all the balls may fail, as shown in Fig. 3, with disastrous results to other parts of the mechanism.

To fit a new key to a taper shaft is an operation that is sometimes necessary when a key has become worn, and, unless done in the right way, will either iesult in the member which is secured to the shaft being eccentric, owing to the key standing too high, or in the key not taking its proper share of the tension. The best way to tackle this job is first of all to drive the member on with a good pressure, as shown in Fig. 4, and to mark the spot where it comes to rest, with a scriber, as shown. It should thee he driven off the shaft and the key fitted to the keyway in the shaft, leaving it slightly higher than is neCessary. The key should be tried in the keyway in the boss, to be sure that it is a tight fit on the sides, then the boss is driven on to the shaft, and it should come to rest at some paint slightly short of the mark previously made. Several trials will enable the fitter to drive the boss home to the mark and to be sin-e that it is hearing at the same time on the key. In fitting keys it is well to bevel their extreme edges off, so as to make surethat they are bearing on the flat faces.