THE DEMOWITABLE REVOWTIOfl

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

by Gibb Grace

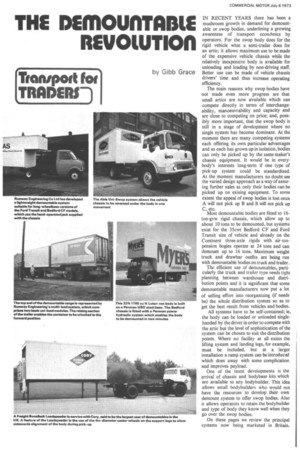

IN RECENT YEARS there has been a mushroom growth in demand for demountable or swop bodies, underlining a growing awareness of transport econdmics by operators. For the swop body does for the rigid vehicle what a semi-trailer does for an artic; it allows maximum use to be made of the expensive vehicle chassis while the relatively inexpensive body is available for unloading and loading by non-driving staff. Better use can be made of vehicle chassis drivers' time and thus increase operating efficiency.

The main reasons why swop bodies have not made even more progress are that small artics are now available which can compete directly in terms of interchangeability, manoeuvrability and capacity and are close to competing on price; and, possibly more important, that the swop body is still in a stage of development where no single system has become dominant. At the moment there are many competing systems each offering its own particular advantages and as each has grown up in isolation, bodies can only be picked up by the same maker's chassis equipment. It would be in everybody's interests long-term if one type of pick-up system could be standardized. At the moment manufacturers no doubt see the varied design approach as a way of assuring further sales as only their bodies can be picked up on exising equipment. To some extent the appeal of swop bodies is lost once A will not pick up B and B will not pick up C, etc.

Most demountable bodies are fitted to 16ton-gvw rigid chassis, which allow up to about 10 tons to be demounted, but systems exist for the 35cwt Bedford CF and Ford Transit size of vehicle and already on the Continent three-axle rigids with air-suspension bogies operate at 24 tons and can demount up to 16 tons. Maximum weight truck and drawbar outfits are being run with demountable bodies on truck and trailer.

The efficient use of demountables, particularly the truck and trailer type needs tight planning between warehouse and distribution points and it is significant that some demountable manufacturers now put a lot of selling effort into reorganizing (if needs be) the whole distribution system so as to get the best result from vehicles and bodies.

All systems have to be self-contained; ie, the body can be loaded or unloaded singlehanded by the driver in order to compete with the artic but the level of sophistication of the system can be chosen to suit the distribution points. Where no facility at all exists the lifting system and landing legs, for example, must be included, but at a larger installation a ramp system can be introduced which does away with some complication and improves payload.

One of the latest developments is the arrival of chassis and bodybase kits which are available to any bodybuilder. This idea allows small bodybuilders who would not have the resources to develop their own demount system to offer swop bodies. Also it allows operators to retain the bodybuilder and type of body they know well when they go over the swop bodies.

On these pages we review the principal systems now being marketed in Britain.

Ulni-Swop Abel Systems Ltd, 22 Chapel Lane, Pinner, Middlesex, HA5 lAD.

Abel Systems Ltd is the largest manufacturer of pneumatically operated demountable equipment in Europe. Design and production is based at Tupton, near Chesterfield, and there is a London office at Pinner. The company likes to work closely with customers and if necessary will carry out a full study of existing distribution systems in order to get the best use from the introduction of demountables. The basic Uni-Swop system is available to Suit rigicis, semi-trailers or rigid plus drawbar configurations and in addition the body units are approved by Freightliners Ltd for carriage by rail. The heart of the Abel Uni-Swop system is the specially designed air-lift packs. These can lift up to 28 tons through a height of 18.5in. Endurance tests on the packs have shown that the air bags are good for 2m operating cycles which is the equivalent of 40 years normal usage. The equipment can be installed on any chassis, semi-trailer or trailer. An advantage of Uni-Swop, says Abel, is that it is simple and robust and it points to instances where equipment up to 10 years' old has been in sufficiently good condition to be remounted on a new chassis. Abel offers its own bodies built in aluminium or Glasonit but customers can specify their regular bodybuilder's product if they so prefer.