Patents Completed.

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

Albion Clutch-Control Gear. Improved "David Brown" Worm Gearing.

Another Shock Absorber. Reliable Steering Mechanism.

Copies 0/ complete specifications of the patents published on this page can be obtained from the Sales Branch, Potent Office, Holborn, WC., at the cost of sixpence for each specification.

AmnoN MOTOR CAR CO., LTD. , and T. B. 31mtri4y, No. .:Ki98, dated26th February, 1915. It is usual in friction clutches to use axial springs to hold the two members of the

clutch in engagement with one another. The operation of disengaging the clutch against the action of this spring or spring entails objectionable end-thri:sts.

The accompanying drawing shows a construction by which'

these end-thrusts are eliminated or balanced. One of the plate members of a clutch is extended to form a sleeve eonc-mtric with the driven shaft, and a surrounding concentric sleeve is scured on the. flywheel which constitutes the other clutch-member. These two sleeves are mounted -inside a casing in hall-bearings. There is one bearing for each sleeve, and a ball thrust-bearing is also provided for each of the sleeves. The clutch-operating pedal is connected to a pair of levers carrying cams interposed between the two thrust-bearings, so that when the pedal is moved the cam engages the thrust-bearings and causes the clutch-members to be diseivaged.

T. A. BELL, No. 22,900, dated 23rd November, 1914. This specification describes a simple friction damping device. Thu main. leaf spring is connected by a link to an arm mounted on is shaft in a casing. This shaft has two cranks which engage by a crankpin the web of a brake-segment.

if a mad wheel drops into a hole the shaft in the casing is turned and the brake-segment lifted off its co-operating surface, so that the rotation is free. When the wheel tries to return to its normal position, the toggle effect of the crank and the brake-segment causes the .brake to be applied and permits only a slow return of the parts.

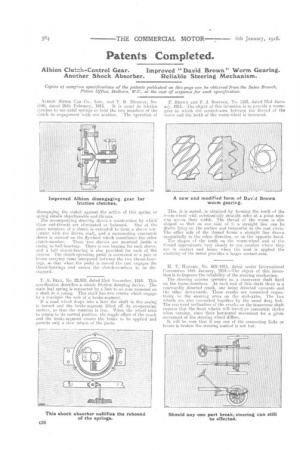

P. BROWN AND F. J. TiosTocx, No. 1103, dated 23rd Jun, 1915.—The object of this invention is to provide a wormgear • in which the contact-area between the thread of the worm and the teeth of the worm-wheel is increased.

This, it is stated, is obtained by forming the teeth of the worm-wheel with substantially straight sides at a point midway across their width. The thread of the worm is also shaped so that on one side of it a straight line can be drawn lying on the surface and tangential to the root circle. The other side of the thread forms a straight line drawn tangentially in the other direction, or on the opposite hand.

The shapes of the teeth on the worm-wheel and of the thread approximate very closely to one another where they are in contact and hence when the load is applied the elasticity of the metal provides a larger contact-area.

H. T. ITAzARD, No. 609/1915, dated under International Convention 14th January, 1914.—The object of this invention is to improve the reliability of the steering mechanism.

The steering column operates on a transverse shaft fixed on the frame-members. At each end of this shaft there is a rearwardly directed crank, one being directed upwards and the other downwards. These cranks are connected respectively to the steering arms on the stub-axles. The two wheels are also connected together by the usual drag link. The rearward inclination of the cranks on the transverse shaft ensures that the front wheels will travel on concentric circles when turning, since their horizontal movement for a given movement of the steering wheel differs.

It will be seen that if any one of the connecting links or levers is broken the steering control is not lost.