n Britain the great lorry weight debate has long centred

Page 24

Page 25

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

around 38 vs 40 tonnes on five axles. Why? Because in 1989 the UK was granted a derogation from the EU's harmonised five-axle 40-tonne limit. But this derogation expires on 1 January 1999, when the UK will finally be forced to accept them.

While the DOT is still busy strengthening bridges to cope with the additional weight, it has quietly added a new and persuasive dimension to the argument. "Lorry Weightsa Consultation Document", made an appearance in early December (CM 19 Dec 1996-1 January 1997), advancing the case for 44 tonnes on six axles on general haulage.

As we reported, this was originally recommended some 16 years ago by the late Sir Arthur Armitage in his ground-breaking report. Since 1994 such vehicles have been permitted, but only when running on intermodal work to and from railheads. On technical grounds it's easy to see why the DOT should support more general use.

Road wear is related more to individual axle loadings than overall gross train weight: 40tonne five axle-attics in the UK will require the drive-axle weight limit to increase from 10.5 tonnes to 11.5 tonnes, with an even greater effect in terms of road wear.

Not surprisingly, the DOT is wary of going down this route. But while six-axle 44-tonners are heavier overall, they can still operate with

in the current 10.5-tonne drive-axle limit. Some bridges will still need strengthening but the cost of doing that could he offset by reduced road wear, avoiding the expense and inconvenience of more frequent re-surfacing. That has to be an attractive option, considering what's been happening to the roads budget. The DOT also believes that allowing six-axle 44-tonners on general haulage could take some 6,500 artics from our roads within five years. That in turn would avoid the cost and pollution of some 490 million vehicle miles a year.

But what would it mean for hauliers? Clearly that 16% increase in weight will need more energy to move it, but that could be offset by the greater efficiency of shifting more weight on the same vehicle.

When restricted 44-tonne operations were introduced three years ago, CM tried to set up a test based around our Scottish Route. Unfortunately, we were overwhelmed by the bureaucracy-we would have needed permission from each county we passed through. Instead we took a double-drive Foden 4350 drawbar from Sandbach to MIRA (CM 8-14 December 1994).

This time, Volvo offered us a suitable vehicle and a route which the company has used for their own tests at 44 tonnes, and this time we could repeat the test at 38 tonnes and produce some comparable results. • THE ROUTE We began the test near Warwick at the Mobil filling station on the A46 just north of Junction 15 on the M40, then followed the A46 north around Coventry, picking up the M6 at Junction 2. We stayed on the M6 northbound to Junction 4 where we turned back south on the A446, effectively following our Midlands tipper route back to the A46 start point.

The A446 is dual carriageway until it becomes the A452 at Balsall Common. From here it was single carriageway all the way back to the A46, via the A4177 towards Warwick. At the A46 junction we headed back to the M40, looped around the Junction 15 roundabout and back to our starting point.

The route measured 77.3km; our original plan was to complete two circuits at 38 tonnes and two at 44 tonnes. Unfortunately the weather had other ideas. Throughout the two days of testing at MIRA and on the road the area was shrouded in freezing fog which forced us to cut the route to a single circuit at each weight. This route is not long enough for a definitive fuel test but since we were comparing results for the same vehicle, the data from both road and track nevertheless presents a fair picture.

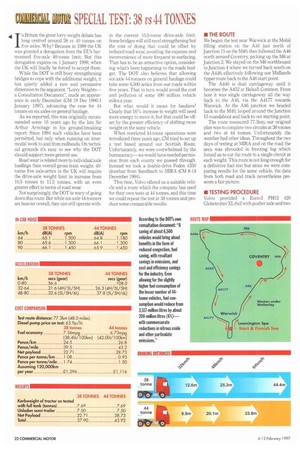

• TESTING PROCEDURE Volvo provided a Euro-2 F1112 420 Globetrotter XL 6x2 with pusher axle and two identical Montracon box trailers loaded to the relevant weights. To reflect common practice we decided to raise the pusher axle and run at 38 tonnes on five axles. MIRA testing was also carried out this way. The test vehicle was fresh out of its box with a token 1,200km showing on its tachograph at the start of the tests. Its newness was reflected in the fuel con surnption results, but on this occasion it was the difference between the two results which interested us (we plan to bring you a frill test of a Euro-2 FH12 later in the year).

• TRACK TESTING

We condensed our MIRA test programme, concentrating on the areas which would show

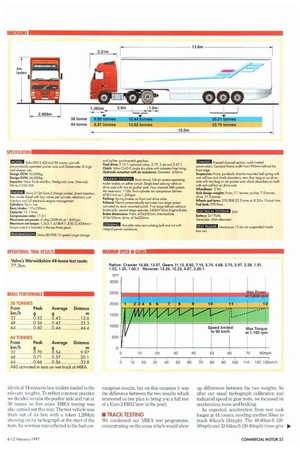

up differences between the two weights. So after our usual tachograph calibration and indicated speed in gear tests, we focussed on acceleration, noise and braking.

As expected, acceleration from rest took longer at 44 tonnes, needing another 50sec to . reach 801unni (50mph). The 48-80km/h (3050mph) and 32-64km/h (20-40mph) times give I,

a good indication of how the 44-tonner can keep up with the traffic. The Volvo was around three and five seconds slower respectively, placing it at no greater disadvantage than a lower powered 38 tonner.

Although the engine was working harder to maintain speed in our constant-speed noise tests, there is no significant difference between the results: the small differences could be accounted for by varying surface conditions, although the track was wet on both occasions.

Our brake test results show the 44-tonner in a favourable light. In all three tests the heavier combination pulled up in a shorter distance—partly due, no doubt, to the sixth axle and increased braking area it provided, but surface conditions may also have played a part. Again the track was wet on both occasions: conditions we would not have considered safe for brake testing without ABS brakes.

Our brake meter showed lower deceleration figures in our 38 tonne tests, which could indicate more water on the track. However, the 44tonner certainly did not point to increased stopping distances as a possible hazard for the heavier combination.

• ON THE ROAD

The reduced performance certainly made its presence felt at the higher weight. Generally we had to make more use of the gear splits than at 38 tonnes, Modifying the FH12 engine to meet Euro-2 involved variable torque output In the three highest gears torque is boosted by 8% to help maintain speed on motorway hills. Even in the lower gears there was adequate grunt to keep the heavier vehi de moving. Using an identical tractor and trailer meant that the payload differed by 6.02 tonnes (22.71 tonnes at 38 tonnes and 28.73 tonnes at 44 tonnes). Since most 38-tonners use a 4x2 tractor which would be lighter than our 6x2 Volvo, the typical difference would work out at less than six tonnes, assuming a switch from a 4x2 tractor to a three-axle unit with the same trailer.

At 44 tonnes the Volvo returned 6.73mpg amund our mixed route, using 9.4% more fuel than the 38-tanner, which finished up with 7.36mpg. A 9% fuel consumption penalty to move 16% more weight seems an acceptable price to pay. Using the prevailing pump price of 63.9p/lit on the test, this translates to a fuel cost of 24.5p/km at 38 tonnes and 26.8p/km at 44 tonnes. Add the different payloads to the equation and the castings swing in favour of the 44-tonner, with 1.08p per tonne/km at 38 tonnes and 0.93p per tonne/km at the higher weight.

Setting aside other operating costs, this is what it would cost in fuel to move each tonne one kilometre with the vehicle fully laden. Over a year covering 120,000km that amounts to £1,296 for the 38-tonner and £1,116 for the 44-tonner.

We recorded identical journey times for both runs. Although we ran in fog both times it was only on our 38 tonne run that it was thick enough to affect our speed, As we have said in previous tests, weather and traffic conditions tend to have a greater effect on speed than vehicle power or weight.

• CONCLUSION

From our tests and the DOT's own arguments in its consultation document it looks as though the costs, technical and envi ronmental advantages all stack up in favour of 44.tonners.

We found that our 44-tanner stopped in a shorter distance than the 38-tonner, had better weight distribution over six axles (implying reduced road wear) and offered a more cost effective means of transport.

Add in the potential to reduce the number of trucks on the road, lowering both fuel consumption and air pollution, and the whole issue could even become a vote winner.

D by John Kendall