Don't blow your top!

Page 73

If you've noticed an error in this article please click here to report it so we can fix it.

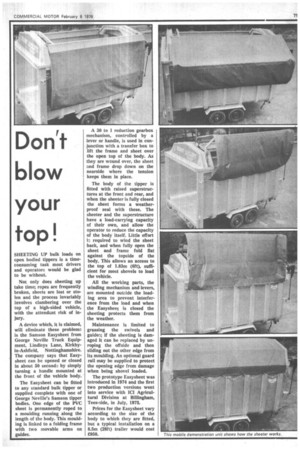

SHEETING UP bulk loads on open bodied tippers is a timeconsuming task most drivers and operator would be glad to be without.

Not only does sheeting up take time; ropes are frequently broken, sheets are lost or stolen and the process invariably involves clambering over the top of a high-sided vehicle, with the attendant risk of injury.

A device which, it is claimed, will eliminate these problems is the Samson Easysheet from George Neville Truck Equipment, Lindleys Lane, Kirkbyin-Ashfield, Nottinghamshire. The company says that Easysheet can be opened or closed in about 30 seconds by simply turning a handle mounted at the front of the vehicle body.

The Easysheet can be fitted to any standard bulk tipper or supplied complete with one of George Neville's Samson tipper bodies. One edge of the PVC sheet is permanently roped to a moulding running along the length of the body. This moulding is linked to a folding frame with two movable arms on guides. A 30 to 1 reduction gearbox mechanism, controlled by a lever or handle, is used in conjunction with a transfer box to lift the frame and sheet over the open top of the body. As they are wound over, the sheet and frame drop down on the nearside where the tension keeps them in place.

The body of the tipper is fitted with raised superstructures at the front and rear, and when the sheeter is fully closed the sheet forms a weatherproof seal with these. The sheeter and the superstructure have a load-carrying capacity of their own, and allow the operator to reduce the capacity of the body itself. Little effort is required to wind the sheet back, and when fully open the sheet and frame fold flat against the topside of the body. This allows an access to the top of 1.83m (61 t), sufficient for most shovels to load the vehicle.

All the working parts, the winding mechanism and levers, are mounted outside the loading area to prevent interference from the load and when the Easysheet is closed the sheeting protects them from the weather.

Maintenance is limited to greasing the swivels and guides; if the sheeting is damaged it can be replaced by unroping the offside and then sliding out the other edge from Its moulding. An optional guard rail may be supplied to protect the opening edge from damage when being shovel loaded.

The prototype Easysheet was introduced in 1974 and the first two production versions went into service with ICI Agricultural Division at Billingham, Tees-side, in July, 1975.

Prices for the Easysheet vary according to the size of the body to which they are fitted, but a typical installation on a 8.5m (28f t) trailer would cost £950.