Loaded to Maximum Capacity, the Seddon Articulated Outfit, Fitted with

Page 32

Page 33

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

the Two-speed Axle, is Capable of Keeping Pace With Similarly ' Laden Traffic. Eight Forward Ratios Afford a Close Selection of Gears for All Road Conditions

THIS week "The Commercial Motor" is able exclusively to give a fully descriptive roadtest report of one of the first Seddon tractor units fitted with the new twinratio rear axle. The tractor unit was loaned by Hall's (Finchley), Ltd., distributor of Seddon vehicles for the London area, and the semi-trailer unit by Carrimore Six-Wheelers, Ltd., North Finchley, London. N.12.

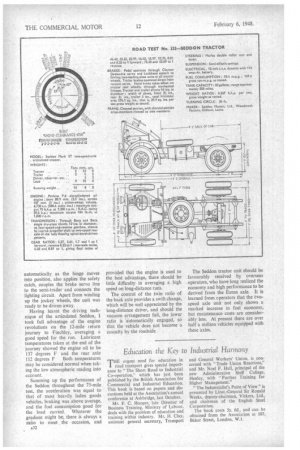

Closely following the specification of the Seddon 5-6-ton chassis, the main difference, apart from the semitrailer coupling gear, is the wheelbase length, which. in the caseof the tractor unit is 9 ft. As in the goods chassis, the Perkins P6 Mark IHN oil engine forms the power unit, with a normal four-speed gearbox and Layrub propeller shaft. A Britishmade version of the Eaton two-speed unit, incorporated in the rear axle, provides a combination of eight for ward and two reverse gears.

Changing Axle Speeds

The axle ratio is changed by a vacuum diaphragm unit located on the differential casing, the controlvalve unit being actuated by a trigger on the gear lever. To engage the high ratio, the trigger is lifted, and to obtain the low ratio, it is depressed.

Interconnected with the control valve, a vacuum gearbox unit incorporated in the speedometer drive provides the necessary adjustment to give a true reading to the instrument for both ratios.

High-efficiency braking is obtained through the Dewandre servo and Lockheed system of the tractor, and the vacuum system of the semi

trailer. In the case of the semitrailer, a reaction valve is fitted to work in conjunction with the tractor foot brake, and a vacuum reservoir is installed affording 10 to 12 brake applications with a stalled engine. The Carrimore automatic contact coupling valve couples the servo pipe-line and seals the vacuum on the tractor when the tractor and trailer are separated.

Maximum Payload The only semi-trailer available for the test was of 8-ton capacity, but to make the test as severe as possible, a 9i-ton payload of concrete blocks was carried—not an advisable procedure, but the only course to adopt in the circumstances. Both tractor and semi-trailer units were shod with 34-in. by 7-in. tyres, twin rear wheels being standardized on the tractor.

Before starting the road test, the turning circles were checked in the Great North Road, where it was ascertained the unit could be turned in 34 ft. A reverse-turn which was made in a by-road proved that with a 22-ft. semi-trailer, the combined unit could be turned in a 27-ft.-wide road. This convinced me that the Seddon did not lack manceuvrability.

On the journey' out of town, the total, running weight was checked at the local weighbridge. It appeared almost incredible that the 70 b.h.p.

engine could provide a good performance when pulling a load bordering on 14i tons, but on the journey to Stevenage we were able to keep pace with most other heavily laden vehicles.

When driving the Seddon I enjoyed the quick change down in axle ratio, which was obtained by just easing the clutch, leaving the throttle wide open, and depressing the control trigger, the result being a smooth and rapid change. Because of the position of the trigger, it is possible to change both axle ratio and gearbox ratio simultaneously.

On inclines, I found the best practice was to start from rest in low axle ratio and low speed of the gearbox, with a direct change to high axle ratio and second gear at 4 m.p.h., subsequent changes in the gearbox being made with the higher axle ratio engaged.

On some of the favourable

stretches of the Great North Road I noticed the speedometer needle creeping up to 36-37 m.p.h. before the fuel-pump governor began to take full action. The road surface was in a particularly slippery condition, and at first I was inclined to take bends at the governed speed and with a tendency to oversteer the tractor, with the result that the tractor appeared to be sliding round the bend.

However, I soon learned to keep the unit under full control on the curves, much to the relief of the Seddon representative, who had tried to appear unconcerned!

Welwyn Hill, a 1-in-12 gradient encountered on the outward journey, brought the Seddon down to 10 m.p.h. in second gear and low axle ratio. Offley Hill, which was the objective for the hill-climbing test, provided a further tax on the vehicle. We paused at the foot of the hill to check the radiator temperature, a reading of 141 degrees F. being obtained.

Checking Radiator Efficiency The start of the 1,000-yd. climb was made on a gradient of Fin 16, and we managed to hold second gear (low axle ratio) on this portion. First gear was engaged on reaching the more severe portion of 1 in 9, and as there appeared to be power in hand, a stop-start test was made at this point. This was accomplished without difficulty, and it was found that the radiator temperature had risen by 10 degrees F. by the finish of the test, atmospheric temperature at the time being 45 degrees F.

The fuel-consumption test was made on the return journey between Stevenage and Hatfield, and included climbing Welwyn Hill from the north side, which again enforced the use of second gear (low ratio). With no traffic delays, an average speed of 20.8 m.p.h. was attained for the course, and the fuel consumption worked out to 10.4 m.p.g

This may appear to be a high rate for the Perkins engine, but, taking the total running weight into consideration and developing the consumption figure into gross ton-mpg., the result compares favourably with those obtained from other vehicles employing the Perkins power unit.

Having regard to the !Ow power-to-weight ratio, the acceleration figures proved to be better than I had expected. Using the high axle ratio and changing through the four speeds of the gearbox, 20 m.p.h, was attained from a standing start in 19 seconds and 30 m.p.h. in 44 seconds It was impracticable to make an acceleration test from 10-30 m.p.h. in top gear, because the engine would be turning at only 600 r.p.m. at 10 m.p.h.

Above Average Brakin6 Upon applying the brakes for an initial brake test, the Seddon tractor was brought sharply to rest with all wheels locked for the final 3 ft of the stopping distance, and, as the results were to prove, braking efficiency was above average From 20 mph. the tractor and semi-trailer unit was brought to rest in 23 ft., equivalent to 58 per cent, efficiency, and from 30 m.p.h. in 45 ft., which corresponds to an efficiency of 67 per cent

At the conclusion of these tests the semi-trailer unit was disconnected from the t r a cto r. Uncoupling proved to be a simple operation of lowering the jockey wheels and tripping the locking device. This was accomplished in 60 seconds, and the tractor driven away from the semi-trailer, an automatic coupling valve sealing oil the brake servo line of the tractor To reconnect the two units, the tracto. was driven back into the guide ramps of the semitrailer until the locking device was tripped into position. This, operation, which is carried out

automatically as the hinge moves into position, also applies the safety catch, couples the brake servo line to the semi-trailer and connects the lighting circuit. Apart from winding up the jockey wheels, the unit was ready to be driven away.

Having learnt the driving technique of the articulated Seddon, I took full advantage of the engine revolutions on the 12-mile return journey to Finchley, averaging a good speed for the run. Lubricant temperatures taken at the end of the journey showed the engine oil to be 137 degrees F and the rear axle

112 degrees F Both temperatures may be considered normal when taking the low atmospheric reading into account.

Summing up the performance of the Seddon throughout the 75-mile test, the acceleration was equal to that of most heavily laden goods vehicles, braking was above average, and the fuel consumption good for the load carried. Whatever the gradient might be, there is always a ratio to meet , the occasion, and

A32 provided that the engine is used to the best advantage, there should be little difficulty in averaging a high speed on long-distance runs.

The control of the twin ratio of the back axle provides a swift change, which will be well appreciated by the long-distance driver, and should the vacuum arrangement fail, the lower ratio is automatically engaged, so that the vehicle does not become a casualty by the roadside

The Seddon tractor unit should be favourably received by overseas operators, who have long realized the economy and high performance to be derived from the Eaton axle. It is learned from operators that the twospeed axle unit not only shows a marked increase in fuel economy, but maintenance costs are considerably less. At present there are over half a million vehicles equip'ped with these axles.