THE COMET GETS A LONGER TAIL

Page 42

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

By John F. Moon

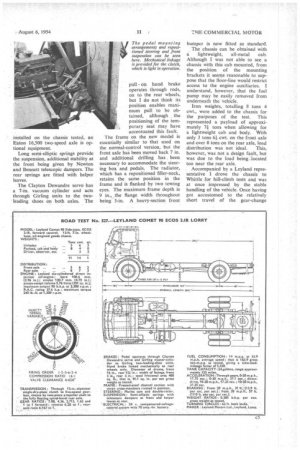

WITH full forward-control, and therefore larger body space without increase of wheelbase, the new range of Leyland Side-type Comet chassis should now appeal to as wide a field of operators in this country as the normal-control model has over the past years in countries overseas. The wheelbase length of these new models has, in fact, been reduced in order to provide better weight distribution and improved handling. With the exception of .a new gearbox, which is now standard on all Comet models, and modified control positions, the Sidetype chassis uses components common. to the normal-control version as tested three years ago.

The goods chassis is available in three wheelbase lengths, these being 13 ft. 7 in., as on the chassis tested, 9 ft. 10 in. for tipper and tractor use, and 14 ft. 8 in. for maximum capacity haulage. Two passenger chassis, identical to the goods range except in respect of their wheelbase, can also be obtained.

The engine is the normal Leyland 5.76-litre direct-injection oil engine, developing 90 b.h.p. at 2,200 r.p.m. and 240 lb,-ft. torque at 1,300 r.p.m. Dry-type cylinder liners are a sliding fit in the monobloc crankcase and cylinder-block casting, removal of these being possible without removing the engine. The castiron cylinder head carries push-rod

operated overhead valves, the exhaust seats being Valmet inserts frozen in place.

A Metalastik rubber-bonded torsional vibration damper is fitted to the front end of the hardened crankshaft, this latter running in seven indium-coated copper-lead bearings. Toroidal combustion chambers are machined in the crowns of the aluminium pistons. The gudgeon pins are off-set towards the thrust side of the piston, this resulting in quieter running. C.A.V. fuel injection equipment is used, the injection pump having a vacuum governor, and Leyland multi-hOle injectors are fitted.

A new type of five-speed constantmesh gearbox is mounted as a unit with the engine. Metalastik sandwich units, in compression and shear, are arranged at the front of the engine and Leyland flexible link mountings at the rear. On the left of the clutch housing is a sprung torque-reactor, and a Lanchesteetype damper is mounted on the gearbox output flange. The latter has been found to cut down transmission vibration, especially on the overrun. Divided propeller shafts with a self

aligning centre-bearing, take the drive to the spiral-bevel final-drive of the fully floating rear axle. Although a single-ratio axle was

installed on the chassis tested, an Eaton 16,500 two-speed axle is optional equipment.

Long semi-elliptic springs provide the suspension, additional stability at the front being given by Newton and Bennett telescopic dampers. The rear springs are fitted with helper leaves.

The Clayton Dewandre servo has a 7-in, vacuum cylinder and acts through Girling units to the twoleading shoes on both axles. The pull-on hand brake operates through rods, on to the rear wheels, but I do not think its position enables maximum pull to be ob tained, although the positioning of the tem porary seat may have accentuated this fault.

The frame on the new model is essentially similar to that used on the normal-control version, but the front axle has been moved back 7 in. and additional drilling has , been necessary to accommodate the steering box and pedals. The radiator, which has a repositioned filler-neck, retains the same position in the frame and is flanked by two towing

eyes. The maximum frame depth is 9 in., the flange width throughout being3-in. A .heavy-section front

bumper is now fitted as standard.

The chassis can be obtained with a lightweight, all-metal cab. Although I was not able to see a chassis with this cab mounted, from the position of the mounting brackets it seems reasonable to suppose that the floor-line would restrict access to the engine auxiliaries. I understand, however, that the fuel pump may be easily removed from underneath the vehicle.

Iron weights, totalling 8 tons 4 cwt., were added to the chassis for the purposes of the test. This represented a payload of approximately 7i tons when allowing for a lightweight cab and body. With only 3 tons 6i cwt. on the front axle and over 8 tons on the rear axle, load distribution was not ideal. This, however, was not a design fault, but was due to the load being _located too near the rear axle.

• Accompanied by a Leyland representative I drove the chassis to Whittle for hill-climb tests arid was at once impressed by the stable handling of the vehicle. Once having got accustomed to the relatively short travel of the gear-change

• lever,. I found it pleasant to use and very suitable for fast changes. The six miles were covered quickly, but the ambient temperature being only 60° F. the temperature of the water in the radiator header tank did not rise above 130° F., and this after scaling Sheep Hill, which has an average gradient of 1 in 8.

As the thermostat is not set to open .until the outlet temPerature reaches 185° F., it was obvious that the chassis would have to be worked hard to obtain any appreciable rise in water temperature. In addition to this, there was no front cowling fitted to the chassis and both engine and radiator were fully exposed to thecool air.

There is a steep hill in Whittle which is mainly 1 in 7, with a maximum gradient of 1 in 5, and which does not allow a run to be taken at it. Starting off in second gear, low gear was necessary at the steepest part, but because of the easy gear change the vehicle was not stopped and it pulled away easily to the crest of the hill. This run was made twice, and whilst the oil temperature rose by two degrees to 142° F., the water temperature remained constant at 130° F.

was reasonably quiet and fan whine was noticeable.

In order , to observe the speedometer during the acceleration 'trials I had to .balance myself on the engine air cleaner, and although uncomfortable, this at least afforded an opportunity to feel the smooth running of the engine. Using second gear from a standing start, the average time required to reach 20 m.p.h. was 17.75 sec., and that to'reach 30 m.p.h. was 37.1 sec. There was no undue engine oscillation when pulling-away from top gear from 10 mph. and after 17.25 sec. we attained 20 m.p.h., a further 20 sec. being necessary to reach 30 m.p.h.

Brake tests were conducted along the same stretch of road, and the figures obtained were very convincing. Applying maximum pedal pressure the chassis was brought to rest from 20 m.p.h. in 31 ft. and an even better figure of 57 ft. resulted from an emergency stop at 30 m.p.h.

The vehicle being new, the brake facings were obviously not properly bedded in, but the retardation was progressive and wheel-locking did not occur. A big pressed-steel reservoir is connected -to the engine exhauster

and, with the engine stationary, was sufficiently large to allow 10 or more Lull-brake applications.

The hand brake, as already remarked upon, was disappointing, the maximum• Tapley meter reading 'being 15%. This would be due partly to the imbedded facings as well as to the lack of straight pull available on the lever, but as the hand brake had shown itself to be quite capable of "holding an llt-ton vehicle on a -steep grade do not attach particular importance to the Tapley reading from .20 m.p.h.

A dear and particularly flat stretch of road was available for the consumption trials, the out and return mileage totalling 7.55 miles. A high average speed was maintained on this run,

there being one stop at the turnround point. Topping up required 4-& pints of fuel, this giving a consumption reading at the rate ,of 14 m.p.g. for an average speed of 33.9 m.p:h.

With a single-speed low-ratio rear axle this figure is good and even better economy would have been shown had a two-speed axle been fitted. This low-ratio, however, combines a useftd top -speed -of 46 m.p.h. with the -ability to climb hills in excess of 1 in 5. With a time-loadmileage factor of 5,550, the • Comet shows itself to be most economical at high speeds when laden.