Patents Completed.

Page 24

If you've noticed an error in this article please click here to report it so we can fix it.

Leyland Transmission. Improved Ideal Plough. The Bauche Hoe.

E. BUGATTI, No. 5407, dated 3rd March, 1914.— The ordinary lockinc,-devices used on the steering gear of motors to prevent blacklash are unsatisfactory owing to the severe vibration to which they are very often subjected.

This specification describes an improved form of split nut for the steering column.

The nut. comprises two faced parts each of which is threaded On the rod, and two faced blocks are interposed between them, one on each side of the rod, so as to maintain the two parts of the nut at their correct relative distance.

The two parts of the nut and the distance pieces are held together by bolts passing right through them. When play develops between the screwed stem and the nut, the distance pieces are removed and slightly reduced in size, so as to bring the two parts of the nut closer to one another. They each, therefore, bear more closely against one side of the screw thread, and the play is thus removed.

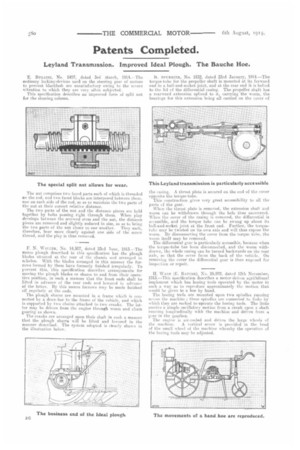

F. N. WALLER, No. 14,507, dated 23rd June, 1913.—The motor plough described in this specification has the plough blades situated at. the rear of the chassis and arranged in echelon. With the blades arranged in this manner the furrows formed by them have formerly finished irregularly. To prevent this, this specification describes arrangements for moving the plough blades or shares to and from their operative position, in such a manner that the front ends shall be lifted in advance of the rear ends and lowered in advanee of the latter. By this means furrows may be made finished off regularly at, the ends.

The plough shares are mounted iii a frame which is connected by a draw-bar to the frame of the vehicle, and which is supported by two chains attached to two cranks. The latter may be driven from the engine through worm and chain gearing as shown.

The cranks are arranged upon their shaft in such a manaer that the plough shares will he lifted and lowered in the manner described. The system adopted is cirearly shown in the illustration below. h. I'1:11,11IE12, No. 1832, dated 23rd January, 1914.—The torque-tube for the propeller shaft is mounted at its forward end in a ball-and-socket joint, and at the rear end it, is bolted to the lid of the differential easing. The propeller shaft has a, rearward extension splined to it, carrying the worm, the bearings for this extension being all carried on the cover of the casing. A thrust plate is secured on the end of the cover opposite the torque-tube. This construction gives very great accessibility to all the parts of the gear. When the thrust plate is removed, the extension shaft and worm can be withdrawn through the hole thus uncovered. When the cover of the casing is removed, the differential is accessible, and the torque tube can be swung up about its ball-and-socket joint at the front end. Further, the torquetube may be twisted on its own axis and will thus expose the worm. .13y disconnecting the cover from the torque tithe, the 'term itself may be removed. The differential gear is particularly accessible, because when the torque-tube has been disconnected, and the worm withdrawn, the whole casing can be turned backwards on the rear axle, so that the cover faces the back of the vehicle. On removing the cover the differential gear is then expesed for inspection or repair.

H. WA DE (E. BAUCHE), No. 25,972, dated 12th November, 1913.—This specification describes a mator-driven agri&iltural implement which has hoeing tools operated by the motor in such a way as to reproduce approximately tha motion that would be given to a hoe by hand. The hoeing tools are mounted upon two spindles running across the machine ; these spindles are connected to links by which they are rocked to operate the hoeing tools. The links receive a simple oscillatory motion from a crank upon a shaft running longitudinally with the machine and driven front a gear in the gearbox. The engine is air-cooled and drives the large wheels of the machine. A vertical acrew is provided in the head of the small wheel of the machine whereby the operation of the hoeing tools may be adjusted.