Australia Wants Vehicles Tailor-made

Page 28

Page 29

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

Australian Operators Require British Vehicles Built to Suit Their Own Requirements B.M.C. Start New Sydney Factory to Cope with Problem

By John F. Moon, A.M.I.R.T.E. WHILST Australia is generally accepted to be the largest potential market for British commercial vehicles, it is also one of the hardest to satisfy. Operators demand specific designs tailored to suit their needs, and efficient spares and servicing arrangements.

This was uppermost in my mind after a 35,000 mile fact finding tour 'organized for the British Press by the British Motor Corporation. This tour, which was of round-the-world propor tions, included three weeks touring the main business centres of the Australian mainland. I was able to glean a little of the problems confronting Australian goods and passenger-vehicle operators, and to gauge with what measure of, success their needs were being met by British manufacturers.

Because of Government import restrictions, which have reduced the number of motor vehicles of all sorts that can be brought into Australia, but particularly those from non-sterling areas, there is a high proportion of British vehicles to be seen in Australia. Nearly all of these arrive into the country completely knocked down, to be assembled by agents, distributors or, in certain cases, by subsidiary depots of the home manufacturers.

The Australians, however, are proud people and whilst this arrangement works fairly satisfactorily, it only partly meets with their approval. They would prefer to see vehicles manufactured completely in Australia, using Australian materials and labour.

Even that would not provide the whole answer: an Australian-built and designed chassis is regarded in many quarters as the only really satisfactory solution. The sales figures of the

Holden car, when compared with those of British cars, are sufficient pointers to the position in this respect.

A26

Many times during the tour comparisons were made between British and American commercial chassis. The general impression seemed to be that American trucks in the mediumcapacity range were slightly more suited to Australian conditions than equivalent British vehicles.

It was obvious that this feeling had arisen partly because, before the 19391945 war, American trucks were irnported in large numbers, and partly because operating conditions in the United States are more akin than British to those in Australia. American vehicles have cabs more suited to longdistance hauls and chassis more resistant to the wear and tear of dirtroad haulage.

This " underground " pro-American feeling has undoubtedly been responsible for the prejudice against oilengined medium-capacity trucks, which is only gradually being broken down by British manufacturers. Oilers are relatively scarce in the United States and despite the latest advances in this field, particularly by proprietary engine manufacturers, the petrol unit is still favoured for both long-distance haulage and short-distance delivery work. In the United States, the reason for this situation is principally that petrol costs are not high and fuel economy is not so important.

This question of fuel prices also applies in Australia, where, despite the recent tax increase of 3d. a gallon, petrol still costs only 3s. 6d. per gallon, equivalent to 2s. 10d. sterling. The

principal drawback to the successful operation of oil-engined vehicles, however, is is the scarcity of efficient servicing arrangements and the extremely high cost involved when they are available.

Few operators can afford to build their own repair shops for fuel-injection equipment and even if they could do so, skilled labour for such work would be hard to find,

Because of the paucity of adequate repair facilities for oilers, a further important consideration affects longdistance inter-state haulage. Should a breakdown occur on a long run the driver might find himself at least 500 miles from the nearest sizeable garage and would possibly be faced with a wait of several days before replacement parts could be sent out to him. Most long-distance drivers can tackle repairs to petrol engines, but, wisely enough possibly, prefer to leave oil-engine repairs to the expert.

_Although, generally speaking, the British medium-capacity petrol-engined vehicle is doing an extremely good job in Australia and largely meeting operators' requirements, there is still a great danger that should dollar restrictions be lifted, the market would become flooded with American chassis.

This does not apply to the heavies, and such makes as A.E.C., Albion, Atkinson, E.R.F., Foden, Leyland and Thornycroft are to be seen in relatively large numbers, many of them working under extremely arduous conditions and receiving few criticisms from their operators.

Most of the heavies, however, are imported completely knocked down, no locally manufactured components other than tyres and batteries being used Whilst not so important as with the medium-weight chassis, this circumstance wounds Australian pride and seriously affects spares and servicing arrangements.

A spares pipeline of 13,000 miles is not conducive to quick repairs unless adequate stocks can be held at principal centres around Australia. In this respect, Leyland Motors, Ltd., seem to be well ahead of other British manufacturers of heavies.

They have well-equipped spares and servicing depots in all the state capitals and have built up a praiseworthy reputation for flying out spares to stranded vehicles. Much of their work in this field pivots about slave replacement parts, which are lent to operators while their own components are being repaired.

The true answer to the repair difficulty undoubtedly lies in manufacturing the vehicles in Australia, The case of the Holden has already been mentioned, but other than light vans and pick-ups of 10.-cwt. capacity, no Holden commercial vehicles are made.

International Harvester have a large factory at Dandcnong, near Melbourne, where trucks are manufactured almost exclusively of Australian parts. Ford and Dodge vehicles are also made in Australia, with the result their operators are much better placed for spare parts than those who run British machines.

A move in the right direction was recently made by the British Motor Corporation, who now have a 56-acre factory site at Victoria Park, Zetland, Sydney. The site of‘ this factory is a once-famous racecourse and it was taken over by the Nuffield Organization in May, 1947, the first factory building being completed in March, 1950.

For five years the Victoria Park plant was concerned with the assembly of Nuffield cars and was fully equipped with paint bays, trim shops and testing department.

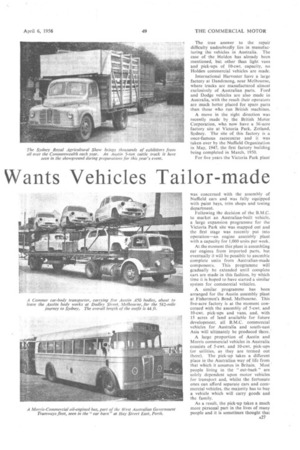

Following the decision of the B.M.C. to market an Australian-built vehicle, a large expansion programme for the Victoria Park site was mapped out and the first stage was recently put into operation—an engine assembly plant with a capacity for 1,000 units per week.

At the moment this plant is assembling car engines from imported parts, but eventually it will be possible to assemble complete units from Australian-made components. This programme will gradually be extended until complete cars are made in this fashion, by which time it is hoped to have started a similar system for commercial vehicles.

A similar programme has been arranged for the Austin assembly plant at Fishermen's Bend, Melbourne. This five-acre factory is at the moment concerned with the assembly of 5-cwt. and 10-cwt. pick-ups and vans, and, with 15 acres of land available for future development, all B.M.C. commercial vehicles for Australia and south-east Asia will ultimately be produced there.

A large proportion of Austin and Morris commercial vehicles in Australia consists of 5-cwt. and 10-cwt. pick-ups (or utilities, as they are termed out there). The pick-up takes a different place in the Australian way of life from that which it assumes in Britain. Most people living in the " out-back " are solely dependent upon motor vehicles for transport and, whilst the fortunate ones can afford separate cars and commercial vehicles, the majority has to buy a vehicle which will carry goods and the family.

As a result, the pick-up takes a much more personal part in the lives of many people and it is sometimes thought that A27

British vehicles of thistype are rather too utility for Australian needs. When compared with such vehicles as the Ford Mainline coupe pick-up, which is based on the Customline private car, it is not difficult to see why.

The Mainline is an extremely attractive vehicle with a long wheelbase and supple springing which make it ideal for dirt-road work. A wide three-man cab affords excellent all-round vision and there is a large shelf behind the seat. An overhead-valve V8 engine gives the vehicle a maximum speed approaching 100 m.p.h.

British pick-ups, for all that, do sell in large numbers and there are utility versions of private cars which have never been seen in this country, such as the Vauxhall, the Triumph Mayflower and the old style of Ford Prefect. A move in the right direction to cater for the comfort demands of pick-up owners has been made by the Austin Motor Co., Ltd., who offer the Hi-Lite coupe

Wrap-around Rear Light

This is based on, and is similar in appearance to, the 10-cwt. pick-up sold in Britain, but the cab and body (made by the Pressed Metal Corporation, Ltd., of Sydney) have more sweeping lines and the rear cab panel is extended to incorporate a wide wrap-around light.

The larger Morris and Austin commercial vehicles have generally also met with a good reception. There were few complaints from the service departments of any of the agents handling them, and apart from slight modifications to suit local conditions, the vehicles are running as designed.

The Austin 30-cwt. 4 x 4 has proved extremely useful for off-the-road work and I was often reminded of the regret that this chassis is no longer in production. There is a large market for British multi-wheel-drive machines of all capacities—a market that is well worth further investigation.

As previously remarked, larger vehicles which fall outside the B.M.C. range are competing successfully with the few Ameritan chassis of similar capacity which are allowed into the country. Reliability is generally good and because of severe Government restrictions on axle loadings and gross weights, overloading is becoming rare.

Severe Weight Restrictions

An eight-wheeled chassis is, for example, restricted to a gross weight of 22 tons, whilst a six-wheeler with twin rear tyres cannot operate at more than 171 tons gross. In view of these relatively light loadings, vehicle failures are rare, but braking systems receive criticism.

Many operators think that the vacuum-assisted hydraulic system does not give a sufficient reserve of power and they fit air-pressure servos, such as those manufactured by Patons Brake Replacements Pty., Ltd. One operator to whom I spoke went so far as to suggest that British chassis should be imported without braking gear.

A28 Locally made equipment is strongly approved by Australian operators, who are increasingly having to rely on Australian spare parts for their British vehicles. Certain concerns, such as Repco, Ltd., manufacture all types of spare part for widely differing classes of chassis, and these spares are not lacking in either quantity or quality. This fact alone serves to substantiate the vital need for adequate spares supplies from Great Britain.

In the passenger-vehicle field, British chassis are used predominantly by all the leading municipalities and by most of the private undertakings. Certain small American petrol-engined chassis are in service, but many of these date from the days of the war, when British products were not available. The swing over to the use of oil engines has been more marked in this field, and most operators now have adequate servicing .arrangements for their fuelinjection equipment.

There are two all-Australian types of btis being built at present which are never likely to be seen in this country. Ansair Pty., Ltd., make one of these, which is built to the American Flxible patents and has proved popular for long-distance coach operation. Allmetal integral construction is employed, with an in-line, vertically mounted engine at the rear. A wide variety of engines is offered, including Cummins, Deutz, Ford, Leyland, Meadows, Perkins and Studebaker.

A feature of the Ansair is that the air intake for engine cooling and breathing is situated in the rear roof panel, and the duct from the roof to the engine compartment is never glazed. This solid rear panel, combined with rather shallow windows, restricts visibility, and for sightseeing purposes these coaches do not compare favourably with current British designs. Nevertheless, reclining seats are fitted and the engine is quiet, so that long-distance travellers find them satisfactory.

The other bus is the Com-Eng Hastings Deering Fleetline 37-seater, which will be described in full next week. This bus follows more conventional British lines in respect of design and layout, and is at the moment available only with a petrol engine, although oil-engined versions are under consideration.

Regulations affecting the operation of goods and passenger vehicles in Australia seem overwhelming to British eyes. The story is told of a prospective operator who asked the Transport Board at Melbourne what he had to do to get into the haulage business. The person who answered his query told him how much his licence, permits and road toll would cost and finished by advising him that it would probably pay him to go into some other business.

The road toll is a new tax which came into force in Victoria last Sunday. Under the regulations all trucks over 4 tons unladen weight will be required to pay id. per ton-mile, this figure being based on the unladen weight plus 40 per cent, of the payload capacity.

It is hoped to collect this money monthly from hauliers and to spend the revenue on the repair and construction of roads. It is difficult to imagine, however, how a really accurate check will be kept on the payload and mileage of thousands of hauliers, and it will be interesting to see whether the scheme works. .

A further restriction has recently been instituted in Sydney by which all vehicles over 3 tons unladen weight are prohibited from parking in the streets and in built-up areas except for the purpose of picking up or delivering goods. This restriction is 'particularly aimed at those hauliers who keep their overheads low by not using garage accommodation for their vehicles.

Other regulations concern the hours travelled per journey, which must be entered in a log book by every driver, so that the police can check that the specified number of hours' rest has been complied with and that the driver has not been speeding. The main bugbear of inter-state hauliers—the inter-state tax of .£1 per ton per mile—was repealed two years ago and heavy haulage between states has been reborn.