From Sheffield.

Page 5

Page 6

If you've noticed an error in this article please click here to report it so we can fix it.

Messrs. Durham-Churchill and Company's Two Competing Types.

Two vehicles in class D and one in class E represent the entries of Messrs. Durham, Churchill and Co., of the Hallatrishire Motor Works, Grimsthorpe, Sheffield. They are distinctive by reason of the particular form of change-speed gear-box which is employed. The general lines on which they are designed and constructed are now pretty well known. A number of passenger vehicles and vans of this make are being operated on some of the hilliest roads in Yorkshire and Derbyshire, and they have given entire satisfaction, notwithstanding the recent accident near Sheffield, which cannot be attributed to any fault in the design of

the chassis. Previous to taking up the manufacture of motor vehicles, this firm was well known for its " Champion " clutches and other power-transmission devices; these were made at its works at Sheffield, and it was, therefore,

well fitted to enter the field of motor manufacture. The firm decided to fit a motor which was already an assured success and, therefore, employs the " Aster." As this make of engine is now built in England, the " Churchill " commercial motor may truly be classed as of " All-British

manufacture. " •

The two vehicles in class D, for loads of 2-tons, are .fitted with four-cylinder, 18-22h.p. " Aster " engines, the cylinders of which are 311 inches in diameter and have a piston-stroke of 51 inches. -A dual system of ignition, with high-tension

magneto, and accumulator and coil, is fitted to the first of these two vehicles, whilst the second one has accumulator and coil ignition only. The larger vehicle (that in class E) is provided with a 24-30h.p. " Aster " engine, which has four cylinders 41 inches in diameter and with a piston-stroke of 54 inches. The ignition is by accumulator and coil. On all these engines the valves are arranged on opposite • sides of the cylinders and are interchangeable. From the engine to the gear-box, the power is transmitted through a " Champion," metal-to-metal friction-clutch. The gear-box, which is the most novel feature of this company's vehicles, is of the " always in mesh " type. All the gear-wheels contained in the gear-box have teeth 11 inch wide and the wheels on the lay-shaft, in addition to having external teeth to mesh with the wheels on the main-shaft,

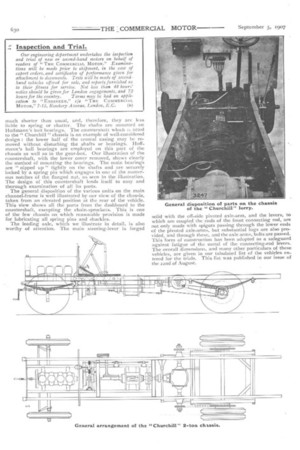

also have internal teeth. .A sliding cam-shaft passes through the centre of the lay-shaft and its object is to lock to the shaft any one of five pinions; the locked pinion, is thrown eccentric with the shaft and some of its teeth are thus brought into mesh with the internal teeth of the lay-, shaft wheel. As there are no sliding gears, the shafts are much shorter than usual, and, therefore, they are less liable to spring or chatter. The shafts are mounted on Hoffmann's ball hearings. The countershatt which is mted to the " Churchill " chassis is an example of well-considered design : the lower half of the central casing may be removed without disturbing the shafts or bearings. Hoffmann's ball bearings are employed on this part of the chassis as well as in the gear-box. Our illustration of the countershaft, with the lower cover removed, shows clearly the method of mounting the bearings. The main bearings are " nipped up " tightly on the shafts and are securely locked by a spring pin which engages in one of the numerous notches of the flanged nut, as seen in the illustration. The design of this countershaft lends itself to easy and thorough examination of all its parts.

The general disposition of the various units on the main channel-frame is well illustrated by our view of the chassis, taken from an elevated position at the rear of the vehicle. This view shows all the parts from the dashboard to the countershaft, excepting the chain-sprockets. This is one of the few chassis on which reasonable provision is made for lubricating all spring pins and shackles. The leading axle, which we illustrate in detail, is also worthy of attention. The main steering-lever is forged

solid with the off-side pivoted axle-arm, and the levers, to which are coupled the ends of the front connecting rod, are not only made with spigots passing through the lower ends of the pivoted axle-arms, but substantial lugs are also provided, and through these, and the axle arms, bolts are passed. This form of construction has been adopted as a safeguard against fatigue of the metal of the connecting-rod levers. The overall dimensions, and many other particulars of these vehicles, are given in our tabulated list of the vehicles entered for the trials. This list was published in our issue of the 22nd of August.