An Improved Starter Gear

Page 36

If you've noticed an error in this article please click here to report it so we can fix it.

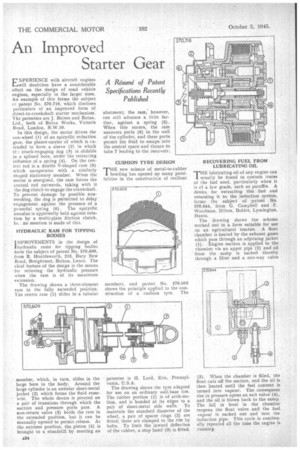

EXPERIENCE with aircraft engines will doubtless have a considerable effect on the design of road vehicle engines, especially in the larger sizes. An example of this forms the subject of patent No. 570,718, which discloses particulars of an improved form of direct-to-crankshaft starter mechanism. The patentees are J. Baines and Rotax, Ltd., both of Rotax Works, Victoria Road, London, N.W.10.

In this design, the motor drives the sun-wheel (1) of an epicyclic reduction gear, the planet-carrier of which is extended to form a sleeve (2) in which th crank-engaging dog (3) is slidable in a splined bore, under the retracting influence of a spring (4). On the central rod is a double V.shaped cam (5) which co-operates with a similarly shaped stationary member. When the motor is energized, the cam forces the central rod outwards, taking with it the dog clutch to engage the crankshaft. To prevent damage by possible nonmeshing, the dog is permitted to delay engagement against the pressure of a powerful spring (6). The epicyclic annulus is apparently held against rotation by a multi-plate friction clutch, In.. no mention is made of this.

HYDRAULIC RAM FOR TIPPING BODIES pIPROVEMENTS in the design of /hydraulic rams for tipping bodies form the subject of patent No. 570,609, from R. Houldsworth, 215, Bury New Road, Breightmet, Bolton, Lancs. The chief feature of the design is the means for relieving the hydraulic pressure when the ram is at its maximum extension.

The drawing shows a three-element ram in the fully extended position. The centre ram (1) slides in a tubular member, which, in turn, slides in the large bore in the body. Around the large cylinder is an annular sheet-metal jacket (2) which forms the fluid reservoir. The whole device is pivoted on a pair of trunnions through which the suction and pressure ports pass. A non-return valve (3) holds the ram in the extended position, but it can be manually opened to permit release. At the extreme position, the.piston (4) is brought to a standstill by meeting an

THE new science of metal-to-rubber bonding has opened up many possibilities in the constructhai of resilient

patentee is H. Lord, Erie, Pennsylvania, U.S.A.

The drawing shows the tyre adapted for use on an ordinary well-base rim. The rubber portion (1) is of arch-section, and is bonded at its edges to a pair of sheet-metal side walls. • To maintain the standard diameter of the wheel, a pair of spacer rings (2) are fitted; these are clamped to the rim by bolts. To limit the inward deflection of the rubber, a stop band (3) is fitted. THE lubricating oil of any engine can usually be found to contain traces of the fuel used, particularly when it is of a low grade, such as paraffin. A device for extracting this fuel and returning it to the induction system, forms the subject of patent No. 570,644, from G. Campbell and F. Woodman, Dilton, Boldre, Lymington, Hants.

The 'drawing shows the scheme worked out in a form suitable for use on an agricultural tractor. A float chamber is heated by the exhaust gases which pass through an adjoining jacket (1). Engine suction is applied to the chamber via an upper pipe (2) and oil from the sunip is sucked thereby through a filter and a one-way valve

(3). When the chamber is filled, the float cuts off the suction, and the oil is then heated until the fuel content is turned into vapour. The consequent rise in pressure opens an exit valve (4), and the oil is blown back to the sump. The fall in level in the chamber reopens the float valve and, the fuel vapour is sucked out and into the induction pipe. This cycle is continually repeated all the time the engine is running.