The Simms Motor Omnibus.

Page 8

If you've noticed an error in this article please click here to report it so we can fix it.

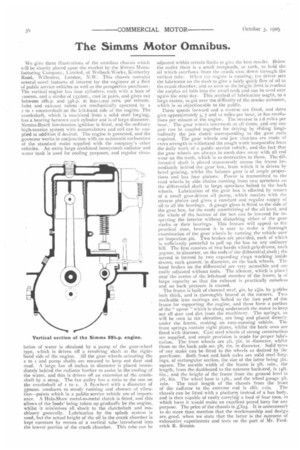

We give three illustrations of the omnibus chassis which will be shortly placed upon the market by the Simms Manufacturing Company, Limited, of NVelbeck Works, Kimberley Road, Willesden, London, N.W. This chassis contains several novel features of interest for the engineer of a fleet of public service vehicles as well as the prospective purchaser. The vertical engine has four cylinders, each with a bore of i2omm. and a stroke of issenn. cast in pairs, and gives out between 28h.p. and 34h.p. at 'Sooaoo revs, per minute. Inlet and exhaust valves are mechanically operated by a 2 to i countershaft on the left-hand side of the engine. the crankshaft, which is machined from a solid steel forging, has a bearing between each cylinder and is of large diameter. Simms-Bosch low-tension ignition is fitted, and the ordinary high-tension system with accumulators and coil can be supplied in addition if desired. The engine is governed, and the governor works in conjunction with an automatic carburetter of the standard make supplied with the company's other vehicles. An extra large combined honeycomb radiator and water tank is used for cooling purposes, and regular circu lation of water is obtained by a pump of the gear-wheel type, which is driven off a revolving shaft at the righthand side of the engine. All the gear wheels actuating the 2 to i and pump shafts are encased to keep out dust and mud. A large fan 18 inches in diameter is placed immediately behind the radiator further to assist in the cooling of the water, and this is driven off an extension of the crankshaft by a strap. The fan pulley has a ratio to the one on the crankshaft of i to 2. A fly-wheel with a diameter of ssomm. conduces to steady running and absence of vibration—points which in a public service vehicle are of importance. A Hele-Shaw metal-to-metal clutch is fitted, and this allows of the loads' being taken up gradually by the engine, whilst it minimises all shock to the clutchshaft and machinery generally. Lubrication by the splash system is used, but the actual height of the oil in the crank chamber is kept constant by means of a vertical tube introduced into the lowest portion of the crank chamber. This tube can be

adjusted within certain limits to give the best results. Below the outlet there is a small receptacle, or tank, to hold the oil which overflows from the crank case down through the vertical tube. Wlu n na! engine is running, tne driver sets the lubricator on the dash to give a fairly quick flow of oil to the crank chamber, and as soon as the height limit is reachea the surplus oil falls into the small tank and can be used over 'again the next day. This method of lubrication ought, to a large extent, to get over the difficulty of the smoke nuisance, which is so objectionable to the public.

Three speeds forward and a reverse are fitted, and these give approximately 3, 7 and t2 miles per hour, at Soo revolutions per minute of the engine. The reverse is 2.8 miles per hour. The gear wheels internutsh at all times, and any one pair can be coupled together for driving by sliding longitudinally the jaw clutch corresponding to the gear ratio required. The gear wheels and jaw clutches are made of extra strength to withstand the rough ‘vork inseparable from the daily work of a public service vehicle, and the fact that the gear wheels are always in mesh does away with all end wear on the teeth, which is so destructive to them. The differential shaft is placed transversely across the frame immediately behind the gear box, from which it is driven by bevel gearing, whilst the balance gear is of ample proportions and has four pinions. Power is transmitted to the road wheels by side chains running from two sprockets on the differential shaft to large sprockets bolted to the back wheels. Lubrication of the gear box is effected. by means of a small gear-driven oil pump, which meshes with the reverse pinion and gives a constant and regular supply of oil to all the bearings. A gauge glass is fitted to the side of the gear box, for the ready ascertaining of the oil level, and the whole of the bottom of the box can be lowered for inspecting the interior without disturbing either of the gear shafts or their bearings. This feature will appeal to the practical man, because it is easy to make a thorough examination of the gear wheels by running the vehicle over an inspection pit. Two brakes are provided, each of which is sufficiently powerful to pull up the bus on any ordinary hill. The first consists of two bands which gripdrums, each soemm. in diameter, on the ends of the differential shaft; the second is formed by two expanding rings working inside drums, each 42omin. in diameter, on the back wheels. The band brakes on the differential are very accessible and are easily adjusted without tools. The silencer, which k places near the centre of the left-hand member of the frame, is of large capacity so that the exhaust is practically noiseless and no back pressure is caused. The frame is built of channel steel, 4in. by 2,11in. by 5-16ths inch thick, and is thoroughly braced at the corners. Two malleable iron castings are bolted to the fore part of the frame for supporting the engine, and these form a portion of the" apron " which is slung underneath the motor to keep out all dust and dirt from the machinery. The springs, as will he seen in the elevation, are long and placed directly under the frame, making an easy-running vehicle. The front springs contain eight plates, whilst the back ones are fitted with thirteen. Cast steel wheels of strong construction are supplied, and ample provision is made for proper lubrication. The front wheels are 2ft. gin. in diameter, whilst those on the back axle are 31t, tin, in diameter. Solid tyres of any make can be fitted to the wheels as desired by the purchaser. Both front and back axles are solid steel forgings, of rectangular section, the size of the latter being sin. square. The outside width of the frame is 3ft. loin_ the length, from the dashboard to the extreme back-end, is 14ft. bin., and the height of the frame from the ground level is 2ft. Sin. The wheel base is sft., and the wheel gauge sft. min. The total length of the chassis from the front of the radiator to the extreme end is iSft. 'tin. The chassis can be fitted with a platform instead of a bus body, and is then capable of easily carryink a load of four tons, in which form it would make an excellent petrol lorry for any purpose. The price of the chassis is .625. It is unnecessary to do more than mention that the workmanship and design are good, when we state that the latter is the outcome of exhaustive experiments and tests on the part of Mr. Frederick R. Simms.