Ball Bearings and their Applications.

Page 11

Page 12

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

It seems to be the general opinion that ball bearings are a refinement suitable for an expensive private car, but an unnecessary luxury in the case of commercial vehicles. This is, however, quite a mistake, because, though the ball bearings may increase the prime cost of a motor vehicle by ,20 to £30, they will considerably reduce the cost of upkeep, and they will make the vehicle much more "fool-proof." In order to explain these views, this article will touch upon the history of ball bearings, and show that the modern accurate ball bearings are as desirable in commercial motor vehicles as in pleasure cars. It was the introduction of ball bearings that made the bicycle such a thoroughly satisfactory machine. In the days of the boneshaker and the first ordinary bicycle with large driving wheels, the bearings were plain journals, as used in all forms of ordinary mechanism. As the amount of energy absorbed by friction is in direct proportion to the circumference of the journal, that is to say, in proportion to the length rubbed through in each revolution, it became the object of bicycle riders to use the biggest wheel that their length of leg would permit, and the cranks were also shortened as much as possible, in order to allow for a larger wheel. At this stage in the development of the bicycle the ball bearing was introduced, and friction became such a small quantity as to be almost negligible. To such a degree was this achieved that 28m. wheels could be made practically as frictionless as 6oin. wheels, and, therefore, the safety bicycle came into existence. But with this reduction of the energy absorbed in friction, it

was necessary to gear up to compensate for the loss of the big wheel, and even to this day it is the custom to speak of a bicycle as geared to so-and-so, mentioning the number of inches that correspond to the diameter of the big wheel which would give the same pedal speed. The weights carried by bicycle ball bearings were comparatively small, and, as the wheels were so large in diameter as compared with the width of the hub, it was necessary to provide means for adjustment. The result was that all ball bearings for bicycles were adjustable, as can easily be seen in Figs. i and 2. In Fig. i the adjustment is made by screwing up the left-hand cone on the spindle, and in Fig. 2 the adjustment is obtained by screwing in the left-hand cup. It is at once obvious, from these drawings, that the load is very curiously transmitted through the balls, as the forces are applied at points about 45 degrees from the vertical, as shown in Fig. 3. In fact, there is always a tendency to shear the balls and not to crush them. At the same time, the motion given to the balls is not a true rolling motion, but, instead, becomes a spinning motion. To guard against undue wear, the cups and cones are always hardened "glass hard" on the surface, but they should be comparatively soft at one sixty-fourth of an inch below the surface, to prevent brittleness. The spinning motion results in some wear, however hard both balls and ball races may be, so that flats are ultimately worn on the bails and grooves are worn on the ball races. When that is the case, the fric tion becomes very considerable. A bearing of better design, primarily intended for use on tricycle axles, was made by William Bowns, Limited, and this is illustrated in Figs. 4 and 5. In this bearing the balls have a true rolling motion, although they make contact at three points. When motor vehicles were illegal in England, but free from restriction in France and Germany, the motorcar came into existence primarily as a glorified tricycle. The early experiments of Daimler in 1885 were made with a bicycle, and Benz in the same year produced a motor-tricycle. These naturally retained the ball-bearing hubs of the pedal-propelled vehicles, but when weight became considerable, and the motor was applied to four-wheel carriages, it was found that the balls ground up and that the ball races were quite unsuited to these vehicles. As a result, ball bearings fell into great disrepute, and, in point of fact, disappeared from motor-vehicle construction for many years. It is true, there was always a tentative use of ball bearings by certain enterprising makers, but it was very rarely they gave satisfaction, whilst, on the ordinary pleasure vehicle's attaining a tare weight of over a ton, the ball bearings practically disappeared. Before dismissing the early period of ball bearings, it must be recalled that they were all enlarged bicycle bearings, in which the balls were held within a cup and cone, and that the same ball race had to take both journal load and thrust. The motorcar has been of enormous benefit to all forms of engineering, inasmuch as it has been the means of introducing improved materials and much greater accuracy of workmanship. Ball bearings are now made with the ball accurate to one ten-thousandth part of an inch, and the ball races are made by automatic machines, and in large quantities, so that a faulty ball race is seldom, if ever, experienced. The modern ball bearing is constructed without any means of adjustment for wear, because if any wear takes place the bearing is faulty and must be immediately replaced ; practically, wear has been eliminated by the extreme accuracy of manufacture and the hardness of the surfaces. Many of the old ball bearings that came to grief were spoilt by the breaking of a ball and the chipping of the ball races, the broken balls or chips being ground up in the bearing and destroying it with more or less thoroughness. There is, therefore, always room on a modern bearing for a broken ball to drop clear of the ball races.

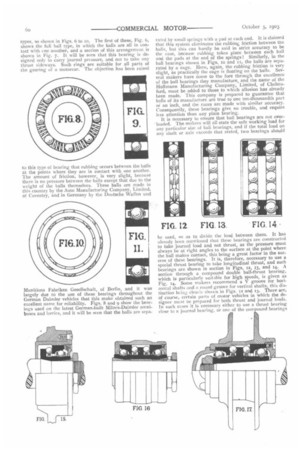

The modern journal bearings are made in three distinct types, as shown in Figs. 6 to to. The first of these, Fig. 6, shows the full ball type, in -.vhich the balls are all in contact with one another, and a section of this arrangement is shown in Fig. 7. It will be seen that this bearing is designed only to carry journal pressure, and not 10 take any thrust sideways. Such rings are suitable for all parts of the gearing of a motorcar. The objection has been raised to this type of bearing that rubbing occurs between the balls at the points where they are in contact with one another. The amount of friction, however, is very slight, because there is no pressure between the balls except that due to the weight of the balls themselves. These balls are made in this country by the Auto Manufacturing Company, Limited, of Coventry, and in Germany by the Deutsche Waffen und Munitions Fabriken Gesellschaft, of Berlin, and it was largely due to the use of these bearings throughout the German Daimler vehicles that this make obtained such an eixellent name for reliability. Figs. 8 and g show the bearings used on the latest German-built Milnes-Daimler omnibuses and lorries, and it will be seen that the balls are sepa rated by small springs with a pad at each end. It is claimed that this system eliminates the rubbing friction between the balls, but this can hardly be said in strict accuracy to be the case, because rubbing takes place between each ball and the pads at the end of the springs! Similarly, in the ball bearings shown in Figs. to and x t, the balls are separated by a cage. Here, again, the rubbing friction is very slight, as practically the cage is floating on the balls. Several makers have come to the fore through the excellence of the ball bearings they manufacture, and the name of the Hoffmann Manufacturing Company, Limited, of Chelmsford, must be added to those to which allusion has already been made. This company is prepared to guarantee that balls of its manufacture are true to one ten-thousandth part oi an inch, and the races are made with similar accuracy. Consequently, these bearings give no trouble, and require less attention than any plain bearing.

It is necessary to ensure that bail bearings are not overloaded. The makers will all state the safe working load for any particular size of bali bearings, and if the total load on any shaft or axle exceeds that stated, two bearings should

he used, so as to divide the load between them. It has already been mentioned that these bearings are constructed to take journal load and not thrust, as the pressure must always be at right angles to the surface at the point where the ball makes contact, this being a great factor in the success of these bearings. It is, therefore, necessary to use a special thrust bearing to take longitudinal thrust, and such bearings are shown in section in Figs, 12, 13, and 14. A section through a compound double ball-thrust bearing, which is particularly suitable for high speeds, is given as Fig, 14. Some makers recommend a V groove for horizontal shafts and a round groove for vertical shafts, this distinction being de:ally shown in Figs. 12 and 13. There are, of course, certain parts of motor vehicles in which the designer must be prepared for both thrust and journal loads. In such cases it is necessary either to use a thrust bearing close to a journal bearing, or one of the compound bearings

(A llieh the Hoffmann Company have made a speciality. These are illustrated in Figs. 15 and lb. The double compound bail bearing is particularly suitable for motorcar hubs, and an application of this is shown in Fig. 17. Although the advantages ea bah bearings are so great they must not be used wnere they are subjected to repeated shocks. Both tee balls and ball races being "glass-nerd " on the surface, they are necessarily brittle, and if the action between them is changed from a rolling action to a continual hammering, chipping is very liable to occur. For this reason they are not used in the hubs of motor vehicles, unless ietnnatic tyres are employed. If no circumferential air cushion is employed to absorb the shocks from the road surface the risk of pulverisation is great, and it is for a similar reason that the attempts to use ball bearings for engine crankshafts has proved abortive, apart from the difficulty of fitting them to this particular part. In the first case the ball races were made in two halves and bolted together over .the journals and crank-pins. Sooner or later the corners of the races where the two halves joined chipped, and then balls and races rapidly broke up. One or two makers tried the expedient of turning the inner race on the crankshalc journal and crank-pin direct, then, after hardening, the outer race was threaded over the crank webs and the balls inserted in situ. This plan was not an entire success, as it proved by its abandonment.

If only plain bearings are employed in a commercial niotnr vehicle, there must always be considerable wear. To localise this as much as possible, it is usual to run steel journals in bronze bushings, or in split bearings usually termed brasses. The bearings are made adjustable, so that the wear on the brasses can be taken up, and at regular intervals it is necessary to look at the bearings and to take up any wear. In some parts, such as the main axle bearings, the wear is considerable, and after a year's heavy work it will probably be necessary to fit new brasses, the original ones being quite worn out. These brasses must be carefully bedded to the shaft, or the bearing will run hot. As ball bearings are made by automatic machinery to exact sizes, it is always possible to replace a damaged ball bearing

without any fitting, and the cost of new ball bearings, should they be necessary, need not exceed the cost of new brasses. A very simple method of fixing the ball races has been introduced by the Hoffmann Company, and is illustrated in Fig. 18. It will be seen that the inner races aro made with a taper on the inside, and a clamping sleeve in the shape of a split cone is put over the shaft, the taper of witich fits the inside of the ball bearing. This sleeve is locked up by a nut, which is further prevented from moving by a small set-screw, and the provision forms a very simple method of fixing a ball race so that it can easily be renewed. Ball bearings should be filled with a stiff motor grease, and they should be so covered in that no dust, or grit can enter. If proper care is taken to exclude dust, the grease will last for as much as two years, and absolutely no attention will be required. The advantage of ball bearings may, in conclusion, be summarised as follows :.—(a) The friction is much less, and, consequently, less fuel and engine power are necessary. (b) If properly screened from dust, no attention is required and no oiling is necessary. (c) The cost of renewal over a period of five or ten years will be much less than the cost of new brasses. (d) The extra cost in the first instance is not very great. From the above it will be gathered that real economy results from the use of ball bearings, and if reasonable care is exercised in their fitting they are as nearly " fool-proof " as any mechanism could possibly be made. The gain in useful propulsive effort is, perhaps, the greatest feature.