Ford Mein 24-•tonesovw

Page 83

Page 84

Page 85

Page 86

If you've noticed an error in this article please click here to report it so we can fix it.

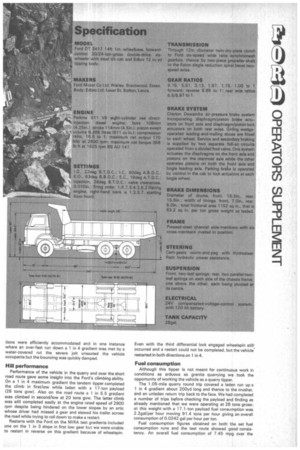

6 X 4 tipper by Trevor Longcroft With double drive and a high articulation bogie. Ford's recently introduced tandem tipper in the D series is aimed especially at off-the-road work, and the model we have just tested had the optional high-clearance "package-, giving 14in. front axle clearance, and an Edbro scow-ended steel body which made it particularly suitable for site work.

The new twin-spring Ford tipper range is designed for on/off road work with gross plated weights of 22 and 24 tons, but although our test vehicle had a manufacturer's plated rating of 24 tons it had an outer-axle spread of less than 18ft and was therefore limited to a maximum of 20 tons on the road, under C and U Regulations.

All the new tandems have Ford synchromesh gearboxes, and the 22-ton tipper has the 360 turbocharged engine, while there is a choice of Perkins V8-511 or Cummins V8-504 for the 24-ton-gvw model. Ours had the Perkins.

The twin-spring bogie suspension available only on the tandem-drive models adds about 265Ib to the unladen weight. The bogie is plated to 18 tons and each of the four springs is identical.

Each spring has two tapered leaves, and the ends of the main leaves are formed into eyes which are rubber bushed to gimbal brackets which encircle the axle-tubes and are pivoted on a fore-and-aft axis to the tubes. This allows the axles to tilt without torsional stresses being imposed on the springs and also allows a height difference of 11in. between wheels on the same side of the bogie.

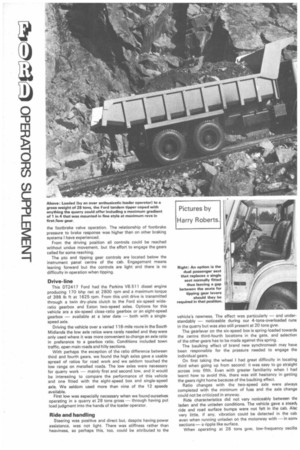

As well as greater axle clearance, the high-clearance package includes a lowered front bumper, stirrup steps below the normal cab step and a one-piece glassfibre front panel in which are set the lowered headlights.

The vehicle showed very good gradient-ability, and presentable fuel consumption, acceleration and braking figures. It was very controllable, but performance was marred by some difficulty in changing gear perhaps because the vehicle was new and stiff, with only 300 miles on the clock. We also found the combination of six-speed gearbox and two-speed axles produced rather more speeds than we could find use for the low-axle 6th. 5th, 4th and 3rd were hardly used during our site and road tests.

General impressions

The cab fitted to the tandem tipper is the familiar 'D' series model; we were impressed by the first-class trim of the de luxe cab together with the high standard of both the dual passenger seat (not-standard) and the driving seat. The driving seat adjusts both up and down, forwards and backwards and has an adjustment for the angle of the squab.

One noticeable omission was a grab handle on the driver's

side of the cab which would have made entering and leaving the cab quicker and easier.

Unlike previous Fords I have driven, this one had a handbrake control that was light to operate and I found little trouble in either applying or releasing it.

The power-assisted clutch was operated by a pendant pedal and the pressure required to disengage the clutch was pleasantly light. The same, however, could not be said for

Below: Controls were well positioned. The indicator stalk and light/horn column protrude radially each side of the steering column below the wheel.

the footbrake valve operation. The relationship of footbrake pressure to brake response was higher than on other braking systems I have experienced.

From the driving position all controls could be reached without undue movement, but the effort to engage the gears called for some reaching.

The pto and tipping gear controls are located below the instrument panel centre of the cab. Engagement means leaning forward but the controls are light and there is no difficulty in operation when tipping.

Drive-line

This DT2417 Ford had the Perkins V8.511 diesel engine producing 170 bhp net at 2800 rpm and a maximum torque of 398 lb ft at 1625 rpm. From this unit drive is transmitted through a twin dry-plate clutch to the Ford six-speed wideratio gearbox and Eaton two-speed axles. Options for this vehicle are a six-speed close-ratio gearbox or an eight-speed

gearbox — available at a later date both with a singlespeed axle.

Driving the vehicle over a varied 116-mile route in the South Midlands the low axle ratios were rarely needed and they were only used where it was more convenient to change an axle ratio in preference to a gearbox ratio. Conditions included town traffic, open main roads and hilly sections.

With perhaps the exception of the ratio difference between third and fourth gears, we found the high axles gave a usable spread of ratios for road work and we seldom touched the low range on metalled roads. The low axles were necessary for quarry work — mainly first and second low, and it would be interesting to compare the performance of this vehicle and one fitted with the eight-speed box and single-speed axle. We seldom used more than nine of the 12 speeds available.

First low was especially necessary when we found ourselves operating in a quarry at 28 tons gross — through having put load judgment into the hands of the loader operator.

Ride and handling

Steering was positive and direct but, despite having power assistance, was not light. There was stiffness rather than heaviness, so perhaps this, too, could be attributed to the vehicle's newness. The effect was particularly — and understandably — noticeable during our 4-tons-overloaded runs in the quarry but was also still present at 20 tons gvw.

The gearlever on the six-speed box is spring-loaded towards the centre third-fourth locations in the gate, and selection of the other gears has to be made against this spring.

The baulking effect of brand new synchromesh may have been responsible for the pressure needed to engage the individual gears.

On first taking the wheel I had great difficulty in locating third when going up from second: it was easy to go straight across into fifth. Even with greater familiarity when I had learnt how to avoid this, there was still hesitancy in getting the gears right home because of the baulking effect.

Ratio changes with the two-speed axle were always completed with the minimum of fuss and the axle change could not be criticized in anyway.

Ride characteristics did not vary noticeably between the laden and the unladen conditions. The vehicle gave a steady ride and road surface bumps were not felt in the cab. Alsc very little, if any, vibration could be detected in the cab even when running unladen on the motorway with — in semi sections — a ripple like surface.

When operating at 28 tons gvw. low-frequency oscilla tions were efficiently accommodated and in one instance where an over-fast run down a 1 in 4 gradient was met by a water-covered rut the severe jolt unseated the vehicle occupants but the bouncing was quickly damped.

Hill performance

Performance of the vehicle in the quarry and over the short road route gave some insight into the Ford's climbing ability. On a 1 in 4 maximum gradient the tandem tipper completed the climb in first/low while laden with a 17-ton payload 128 tons gvw). Also on the road route a 1 in 5.5 gradient was climbed in second/low at 20 tons gvw. The latter climb was still completed easily at the engine rated speed of 2800 rpm despite being hindered on the lower slopes by an artic whose driver had missed a gear and siewed his trailer across the road while trying to roll down to make a restart.

Restarts with the Ford on the MIRA test gradients included one on the 1 in 3 slope in first low gear but we were unable to restart in reverse on this gradient because of wheelspin. Even with the third differential lock engaged wheetspin still: occurred and a restart could not be completed, but the vehicle restarted in both directions on 1 in 4.

Fuel consumption

Although this tipper is not meant for continuous work in conditions as arduous as granite quarrying we took the opportunity of working the vehicle as a quarry tipper.

The 1.05-mile quarry round trip covered a laden run up a 1 in 4 gradient about 200yd long and thence to the crusher. and an unladen return trip back to the face. We had completed a number of trips before checking the payload and finding as already mentioned that we were operating at 28 tons gross: at this weight with a 17.1-ton payload fuel consumption was 2.2gal/per hour moving 91.4 tons per hour giving an overall consumption of 0.0242 gal per hour per ton.

Fuel consumption figures obtained on both the set fuel consumption runs and the test route showed good consistency. An overall fuel consumption of 7.45 mpg over the route was representative of all types of road conditions likely to be met by a vehicle of this type. They included a climb of Sun Rising Hill with an average gradient of 1 in 6.5 and a maximum gradient of 1 in 5.5 and all types of running from traffic to dual-carriageway trunk roads.

Essentially this Ford will find its niche in construction site work, and drivers will find it a quiet and comfortable vehicle — a major factor when so many site vehicles are ownerdriven. As tested with a list of optional extras including a brush guard in front of the grille, a power-assisted clutch, spare wheel, high-lift "package" and Michelin steel-cord radials the vehicle costs £5507.00, and the Edbro body an additional £1180.