NEW MODELS

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

at the Dairy Show

ever the controller tiller is raised or released. To comply with regulations, a parking brake is also fitted; this, in turn, is interconnected with the controller, so that the current cannot be applied until the brake is released. In the braking system there are two 7-in. drums, with internal-expanding units on the rear wheels and a transmission arrangement which is connected to the parking brake.

The chassis frame is a rectangular all-welded pressed-steel channel-section structure, with. superimposed crossbearers to support the body. It is reinforced at points where heavy stresses are likely to be encountered. The machine has a wheelbase of 4 ft. 4 ins. and a 3-ft. track at the front and rear. It is claimed that the Electruk can be turned in a circle of 15-ft. 6-in. diameter.

The I-section beam used for the front axle has centre-point stub axles. and Ackerman steering gear actuated by sideways movement of the tiller. The rear axle is an orthodox E.N.V. unit, with double-reduction helical and spiralbevel drive, and a differential. A torquereaction spring connects the rear axle to the chassis frame, to-absorb stress loads when accelerating or braking.

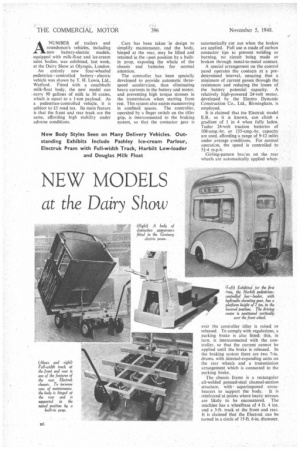

Another new electric model, shown for the first time, was the Harbilt pedestrian-controlled low-loader with hydraulic platform-elevating gear. Although small in size, it is robustly constructed and has a 1-ton payload capacity. Basically it employs the same electrical components as other Harbilt models. It has a 2 h.p. 24-volt

compound-wound traction motor which is positioned vertically over the front wheel. Chain drive is used between the motor and front wheel, the transmission passing through a two-stage reduction.

Power control-switch and braking arrangements are attached to the steering lever, which operates directly on the front axle. Equipped with 24-volt 84-amp.-hr. batteries, the low-loader has a useful range for a day's work, and is controlled in speed to 1 m.p.h. for manceuvring and 2i m.p.h. in direct drive. The front wheel is braked by means of a 7-in, internal-expanding unit.

Low-loading Platform

In the lowered position the loading height is 7 ins., which is increased to 10 ins, when the platform is fully elevated. The platform length . is 3 ft. 3f ins., and overall length of the truck complete is 6 ft. 6 ins. It has a useful turning circle of 10 ft. Solid tyres are fitted on all three wheels, the front tyre being 13 ins, in diameter and 6 ins, wide, whilst those at the rear are 6 ins, in diameter and 4 ins. wide. This model is produced by the Harborough Construction Co., Ltd., Market Harborough, Leicester.

The Douglas 15-cwt. three-wheeled milk float made its debut at the Show. It is capable of accommodating 30 standard 20-pint crates in two layers. Based on the industrial model, it is powered by the Douglas 596 c.c. horizontally opposed air-cooled side valve petrol engine. Drive from the engine is transmitted through a Borg and Beck clutch and a spur and bevel gear direct to the front wheel. The overall gear reduction is 20 to 1.

Steering takes effect on the front wheel, and the machine is reversed by turning the front wheel through an angle of 180 degrees from the forward position. Simplicity is the keynote of the design of the controls, the accelerator and brake pedals being operated by the right foot, whilst the "dead-man " clutch pedal is actuated by the left foot. There is no gearbox, the engine speed being controlled to give a maximum of 8 m.p.h.

A novel braking system is employed, the front wheel being retarded through an external-contracting band which takes effect on an extension of the drive shaft. This is linked to the handbrake lever, and a simple means for adjustment for wear is provided. Oirling units, located on each of the rear wheels, are actuated by the pedal, the drums being 8 ins, in diameter and 1,1 ins. wide. Interchangeable cast wheels are equipped with 18-in. by 7-in. pneumatic tyres. Semi-elliptic leaf springs carry the rear axle.

The body and cab have an all-metal frame mounted on a hardwood base. Panelling is of 20-gauge steel. sVith I8-gauge aluminium sheeting for the roof. Doors can be fitted to the cab if required, the driver being protected at the front by a full-width Triplex screen. Electrical equipment includes coil ignition, 6-volt lighting system, windscreen wiper and horn.

Overall length of the van is 11 ft. 10 ins., of which loading space accounts for 6 fr. 1 in. The platform is 4 ft. 6 ins, wide and goods may be loaded to a height of 3 ft. 4 ins. The turning circle is 19 ft. 9 ins. The vehicle is priced at £350 and is made by Douglas (Kingswood), Ltd., Bristol.

One of the outstanding exhibits was the Pashley ice-cream parlour body, which was shown fitted to a Brockhouse 2-ton two-wheeled trailer. This model was first thought of three weeks before the Show was opened. During that short spice of time it passed through the drawing-board stage, and construction and painting were finished three days before the Show began.

With a light-alloy body, the complete unit weighs 30 cwt.; a further 10 cwt. being added by 20 gallons of water, 4 cwt. of ice-cream and other supplies. The back and sides of the body are given a modern appearance by full-depth corrugated Perspex sheets which are set in rubber fillets.

Dual-purpose Pillars

In addition to supporting the roof, the tubular pillars also carry the water supply, which is fed to a self-contained heater and collapsible sink. Illuminaved • leaded-glass panels are let in to the front of the counter, whilst the main section of the counter is fully insulated to carry the ice-cream containers. Waste water from the sink is conducted away to a tank beneath the floor.

Advantage is taken of the space in the wheelboxes to carry 12-volt batteries, which supply current for the counter and interior lights, the latter being attractively covered with shellpattern shades. A Calor-gas cylinder for the water heater is also accommodated in one of the wheelboxes.

Removable steps, leading up to the counter and seats, are carried in the trailer when it is being moved, lightalloy, corrugated sheets being used to cover the open side of the body.

The body was built by W. R. Pashley, Ltd., Chester Street, Birmingham.