WHAT DOES THE SHUTTLE

Page 36

Page 37

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

SERVICE SAVE?,

may be called upon for an occasional journey from one factory to another. This is important. It is not practicable to arrange that one or two or even three vehicles and no more shall be allocated for this inter-factory transport: any one of the 15 may have to do that work. This means, of course, that every vehicle must be fully licensed and insured.

Suitable loading Pays are provided for the different materials, except the scrap, which is loaded from a heap on the ground. What I have called the internal factorytransport consists almost exclusively of conveying the different materials from the appropriate loading bays within the factory premises to a railway siding, also on those premises. The maximum distance over which goods have to be carried within any of the factories is half a mile.

The question put was whether it would not be more economical to use, say, a couple of tractors in each factory, together with five trailers of the quick-detachable type in, place of the orthodox four-wheeled 5-tonners now in service.

My answer was the obvious one, that there would be an economy in the use of the tractor-trailer type of vehicle.

Calculations Bring a Surprise I have gone into the problem in detail below and I am rather surprised to find that whilst there is an economy, it is not so great as I had anticipated and it is for that reason more than any other that this article has been written. It will give opportunity for criticism-to those who have had experience of this class of work and who may therefore see flaws in my argument.

make the following assumptions. First that there be five vehicles to each of the three factories; second, that only two drivers be employed with the five vehicles. If this involves the drivers in walking too far, I suggest hooking a bicycle onto the vehicle.

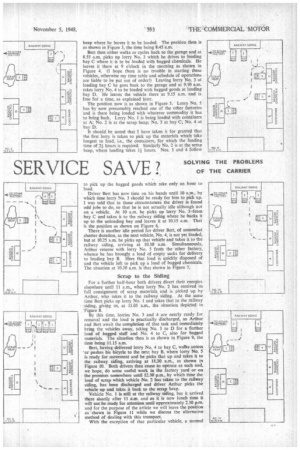

The series of diagrams shows the position from time to time, throughout what I might term a cycle of operations.

Figure 1 shows the situation at 8.30 a.m., when work is about to commence. On the right are shown three loading bays, A for containers. B and C for bagged chemicals. At D is another bagged-chemical loading bay, and at top left is the scrap heap. At the lower end of the diagram is the garage for the five vehicles, at the upper end the railway siding and a road leading off left to one of the other factories.

At 8.30 a.m., then. driver Arthur sets off with vehicle No. 5 to one of the other factories. Driver Bert picks up lorry No. 1 and drives it to loading bay A where he backs it up to the platform and leaves it to be loaded with containers. The situation at 8.35 a.m. is that shown in Figure 2.

Driver Bert walks back to the garage, which he reaches at 8.40 a.m., picks up lorry No. 2 and drives it to the scrap to pick up the bagged goods which take only an hour to load.

Driver Bert has now timc on his hands until 10 a.m., by which time lorry No. 3 should be ready for him to pick up. I was told that in those circumstances the driver is found odd jobs to do, so that he is not actually idle although not on a vehicle. At 10 a.m. he picks up lorry No. 34rom bay C and takes it to the railway siding where he backs it up to the unloading bay and leaves it at 10.15 a.m. That is the position as shown on Figure 6.

There is another idle period for driver Bert, of somewhat shorter duration, as the next vehicle, No. 4, is not yet loaded, but at 10.25 a.m. he picks up that vehicle and takes it to the railway siding, arriving at 10.30 a.m. Simultaneously, Arthur returns with lorry No. 5 from the other factory, whence he has brought a load of empty sacks for delivery to loading bay B. Here that load is quickly disposed of and the vehicle left to pick up a load of bagged chemicals. The situation at 10.30 a.m. is that shown in Figure 7.

Scrap to the Siding For a further half-hour both drivers divert their energies elsewhere until 11 a.m., when lorry No. 2 has received its full consignment of scrap materials and is picked up by Arthur, who takes it to the railway siding. At the same time Bert picks up lorry No. 1 and takes that to the railway -siding, giving us, at 11.05 a.m., the situation depicted in 'Figure 8.

By this time, lorries No. 3 and 4 are nearly ready for removal and the load is practically discharged, so Arthur and Bert await the completion of that task and immediately brine the vehicles away, taking No. 3 to D for a further load of bagged stuff and No. 4 to C, also for bagged materials. The situation then is as shown in Figure 9, the time being 11.15 a.m.

Bert, having delivered lorry No. 4 to bay C, walks across or pushes his bicycle to the next bay B, where lorry No. 5 is ready for movement and he picks that up and takes it to the railway siding, arriving at 11.30 a.m., as shown in Figure 10. Both drivers then cease to operate as such and, we hope, do some useful work in the factory yard or on the premises somewhere until 12.10 p.m., by which time the load of scrap which vehicle No. 2 has taken to the railway siding, has been discharged and driver Arthur picks the vehicle up and takes it back to the scrap heap.

Vehicle No. 1 is still at the railway siding, but it arrived there shortly after II a.m, and as it is now lunch time it will not be ready for attention until approximately 2.30 p.m. and for the purpose of the article we will leave the position as shown in Figure 11 while we discuss the alternative method of dealing with this transport.

With the exception of that particular vehicle, a normal cycle of operations has been completed. We may take it that it will continue for the rest of the day. It may be that lorry No. 1, when brought from the railway siding, will again be backed up to the container loading bay at A and will probably be finished loading by the time work stops and backed into the garage ready for its first journey in the morning, the other vehicles continuing with their loads of bagged goods and scrap after the manner just described. I am going to assume that there be no need for any of these five vehicles to leave the factory yard again during that day.

If I assume that the same procedure be adopted when using the articulated tractor-trailer outfits, I need not draw a fresh series of diagrams. I can assume that the two drivers are each in control of a motive unit and that they pick up their respective trailers and handle them in the same way as they now handle the four-wheeled 5-tonners. That • is to say, at 8.30 a.m. Arthur, with his motive unit, will pick up trailer No. 5 and proceed to one of the other factories, while Bert will pickup trailer No. 1 and take it to loading bay A for a load of containers. The advantage from the driver's point of view, of course, is that he will not now need to walk or cycle after having detached his motive unit, • but can drive straight back to the garage to pick up the next trailer. I cannot, however, see that the times and sequences of operations will differ in any way from those already described.

• Scope for Greater Economy ?

It is here that I may be found to be at fault and I shall not be in the least offended if some expert in the use of the tractor-trailer combination spots the error and writes to mo about it. It may be that there is a more economical way of employing this type of transport equipment, something which I have overlooked which will expedite matters and show economies even greater than those which I am about to indicate by calculation of the cost of operation of these two sets of equipment,

The first step towards that calculation is to assess the weekly mileage to be covered. We can do this by reference to the diagrams. On Figure 2 we can deduce that lorry No. 5 in its trip to another factory, say, six miles away, making a return journey and perhaps having to travel a further half-mile in each direction inside the two factories visited, will run 13 miles. Vehicle No. I will travel only a short distance, but we will assume a quarter of a mile for that. Vehicle No. 2, as shown at Figure 3, will travel a bare half-mile, but we will credit that distance to it.

Similarly, we will credit No. 3 on Figure 4 another halfmile; vehicle No. 4 on Figure 5 a quarter of a mile; vehicle No. 3 on Figure 6 a quarter of a mile; vehicle No. 4 on Figure 7 half a mile; vehicle No. 1 on Figure 8 half a mile; vehicle No. 2 on Figure 8 a quarter of a mile; vehicle No. 4 on Figure 9 a quarter of a mile; vehicle No. 3 on Figure 9 half a mile: vehicle No. 5 on Figure 10 a quarter, and No. 2 on Figure 11 a further quarter. The total,for approximately half a day is 171 miles and, altogether, it may be taken that in the one day a total of perhaps 25 miles will be covered. Not all the vehicles make a double journey. On a five-day week that is 125 miles. In the case of the articulated vehicles the mileage will be greater—perhaps not double, but, say, 25 per cent, more. which is 156 per week.

The running costs will approximate to 5d. a mile as follows:—Petrol and oil, assuming petrol to be consumed at about 8-9 m.p.g., 3d.; tyres, /d. and maintenance, 11d. Thus the total running cost will be £2 12s. per week to the nearest shilling for the orthodox vehicles, but that for the articulated vehicles will be £3 6s., these figures approximating to £135 and £172 per annum respectively.

Now for the standing charges. First as regards the orthodox four-wheelers. There are five of these and the total cost will be approximately £3,200, so that the item "interest" in our standing charges will be £96.

The five sets of tyres will cost approximately £500. leaving £2,700 net. I am going to assume that the vehicles be employed on this service for eight years before they are disposed of, at which date the maximum residual value for the five will be no more than £300, leaving £2,400 on which to calculate depreciation, which is £300 per annum.

As regards the tractor-trailer outfits, I shall assume that the two motive units cost £1,200 and that the five trailers cost altogether £1,600, giving £2,800, so that the interest item will be £84 per annum. Tyres will be £350 and deducting that from £2,800 leaves £2,450. I deduct £250 from that as residual value and I get £2,200, so that my depreciation is £275 per annum.

Costs Totalled

Now for the other items of standing charges. First of all, for the five orthodox four-wheeled vehicles, the cost of the Road Fund licences will be £150. Here is the importance of the point that I have already mentioned, that, as any vehicle may he required to go on the roads, all of them must be fully licensed. Wage costs, assuming the drivers are paid on the Road Haulage Act scale, will be £286; garage rent for five vehicles will be £50. That is admittedly a nominal sum, as the vehicles are parked in a shed within the factory. Insurance costs £75, interest from above, £96. and depreciation also from above, £300, the total being £957.

Now for the tractor-trailer combinations. The Road Fund licences for the five trailers and the two tractors will cost £60. Wages, as in the other case, will be £286, rent— I have taken £10 per trailer and £10 per motive unit-170. insurance, £30, interest £84, depreciation, £275, total £805.

The saving resulting from the use of the articulated vehicles is in the difference in the standing charges. From that £152 must be deducted the £37 extra running cost of the tractor-trailers for extra mileage. Net saving per factory is £115 and for three factories f345 per annum, S.T.R.