DESIGNING TI-11 .AIRY VAN

Page 118

Page 119

If you've noticed an error in this article please click here to report it so we can fix it.

to Give Arnt

am and Easy Access

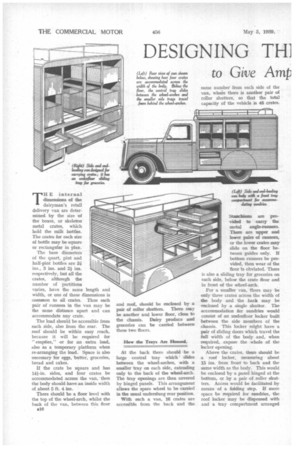

Bodies of Dairy Vans for House-to-house Deliveries Need Careful Design to Obtain Maximum Capacity and Permit Ease of Loading and Unloading TH E internal dimensions of the dairyman's retail delivery van are determined. by the size of the boxes, or skeleton metal crates, which hold the milk bottles. The crates for each size of bottle may be square or rectangular in plan.

The base diameters of the quart, pint and half-pint bottles are 3i ins., 3 ins. and 2,1 ins. respectively, but all the crates, although the number of partitions varies, have the same length and width, or one of these dimensions is common to all crates. Thus each pair of runners in the van may be the same distance apart and can accommodate any crate.

The load should be accessible from each side, also from the rear. The roof should be within easy reach, because it will be required for " empties," or for an extra load, also as a temporary platform when re-arranging the load. Space is also necessary for eggs, butter, groceries, bread and cakes.

If the crate be square and has 144-in. sides, and four crates be accommodated across the van, then the body should have an inside width of about 5 ft. 4 ins.

There should be a floor level with the top of the wheel-arch, whilst the bark of the van, between this floor 816 and roof, should be enclosed by a pair of roller shutters. There may be another and lower floor, close to the chassis. Dairy produce and groceries can be carried between these two floors.

How the Trays Are Housed.

At the back there should be a large central tray which slides between the wheel-arches, with a smaller tray on each side, extending only to the back of the wheel-arch. The tray openings are then covered by hinged panels. This arrangement allows the spare wheel to be careied in the usual underslung rear position.

With such a van, 16 crates are accessible from the back and the same number from each side of the van, where there is another pair of roller shutters, so that the total capacity of the vehicle is 48 crates.

Stanchions are provided to carry the metal angle-runners. There are upper and lower pairs of runners, or the lower crates may slide on the floor between guides only. If bottom runners be provided, then wear of the floor is obviated. There is also a sliding tray for groceries on each side, below the crate floor and in front of the wheel-arch.

For a smaller van, there may be only three crates across the width of the body and the back may be enclosed by a single shutter. The accommodation for sundries would consist of an underfloor locker built between the side members of the chassis. This locker might have a pair of sliding doors which travel the full width of the body and, when required, expose the whole of the locker opening.

Above the crates, there should be a roof locker, measuring about 15 ins, from front to back and the same width as the body. This would be enclosed by a panel hinged at the bottom, or by a pair of roller shutters. Access would be facilitated by means of a folding step. If more space be required for sundries, the roof locker may be dispensed with and a tray compartment arranged across the body, immediately behind the front bulkhead. This seems to be quite a good scheme.

Instead of loading the crates above the top of the wheel-arch, as many as possible can be carried on runners close to the chassis in front of the wheel-arch. With the forwardcontrol type of chassis, it may be possible to carry half the load of crates in front of the wheel-arch and about 10 ins, lower thanthe other half of the load which is above the wheel-arch. The space at the top. above the lower portion of the load, may be utilized for grocery trays which are the same width as the crates.

Controlled Streamlining.

If a streamlined type of body be required, including a shaped back, then the back curve should be a moderate one, so that there is no undue waste of space.

In some instances, extra ease of access to the driving compartment is specified. With sufficient length of driving compartment, it may be possible for a sliding door to be mounted which travels within the overall length of the cab. The door on one or both sides of the body may be left open during the round of calls, and the vehicle then has practically

the same ease of entry as a doorless one.

For a dairy van which is usually a side-loader, it is undesirable for a sliding door to encroach into the loading portion. Therefore, if the door travel cannot be confined to the

cab, the door is omitted on both sides, or on the near side only.

The sliding door, however, may he utilized for -the sides of the body. In order to provide a side opening of approximately two-thirds of the length of the body, there should be a pair of sliding doors. Each door has a separate runway, so that both may be pushed behind the fixed rear side-panel. The doors should be made up in metal frames so as to be as thin as possible and the casing, which conceals the doors on the inside, should have the rear craterunners attached to it.

To save weight light-metal fittings can be used.