A BRITISH

Page 104

Page 105

If you've noticed an error in this article please click here to report it so we can fix it.

OIL ENGINE for

LIGHT VEHICLES

Exclusive Account of the Interesting Perkins Unit in Sizes for Vehicles of 1-ton to 3-ton Pay-load Capacity. An Engine of 3 -in. Bore that Runs Smoothly at Above 4,000 r.p.m.

THE British commercial-vehicle market has long awaited the advent of a small British-made oil engine for vehicles carrying two tons and even less. In our issue dated June 21, 1932, we announced the formation of F. Perkins, Ltd., Queen Street, Peterborough, and 55, Pall Mall, London, S.W.1, the managing director of which (Mr. F. Perkins) was previously managing director of Aveling and Porter, Ltd., Rochester, and associated with Barford and Perkins,. Ltd., Peterborough, so that the new company had a wealth of oil-engine experience upon which to base its declared policy of producing roadtransport oil engines.

For many months we have known of the experiments proceeding with the first type to be produced by the company—a four-cylindered unit of 14.4 h.p., R.A.C. rating—and we are now able to publish a full and exclusive description of the engine, which is already in production.

"Pours" and "Sixes."

The 14.4 h.p. engine has a bore of 3 ins. (76 mm.) and a stroke of 41 ins. (120.65 mm.), the capacity being 2189 litres and the maximum power about 42.8 b.h.p., so that it will be suitable for 25-cwt. vehicles. We have seen this engine running• and have ridden in a Hillman car in which it WAS fitted. A modification of it, with 85 mm. bore (giving 2.738 litres capacity), is being developed for 2-tonners, 21-tonners, 20-seaters, etc., also one of 80 mm. bore. A sixcylindered unit with the same optional bores will shortly be available, so that the entire range will cover roughly from 14-40 h.p. to 30-70 h.p.

The engine is . probably the first small high-speed oil engine on our market, being comparable, so far as torque and speed characteristics are concerned, with advanced designs of petrol engine of the same dimensions.

D30 As regards performance, the power curve rises steadily to an apex at about 3,000 r.p.m., and we have observed the smaller engine running smoothly above 4,000 r.p.m. This high speed is possible, no doubt, partly because of the shortness and stiffness of the crankshaft, also the rigidity of the main engine casting. No maximum-speed governor is considered necessary.

The torque curve is almost flat from 1,0()0 r.p.m. to 2,400 r.p.tn., the maximum reading being 89 lb.-ft., whilst the maximum b.m.e.p. is about 100 lb. per sq. in. Fuel consumption is in the order of 0.45 pint per b.h.p.hour and, by way of interest, the Hillman ear with the 14.4 h.p. engine and a gross weight of about 35 cwt. does 30 miles to the gallon of Diesel oil. A drive in this car served to demonstrate the absence of "Diesel knock" or rough period, also the freedom from smoke in the exhaust, throughout the useful power and speed range when under load. Performance curves and other data appear on pages 422-424.

So far as the combustion system is concerned, a form of ante-chamber is employed, and C.A.V.-Bosch injection pump and flange-type injectors are used. Besides the combustionchamber design, which is entirely novel, numerous other features are covered by world patents. The injection and combustion principle is such as to give easy starting from cold without the use of heater coils or decompression devices, and we were able to start the engine by hand when it was warm: The injection pressure is about 1,500 lb. per sq. in. and the compression ratio 16 to 1.

Extreme rigidity characterizes the construction, for the main block is carried down to 41 ins, below the crankshaft axis, and is of an alloy having a chromium content.

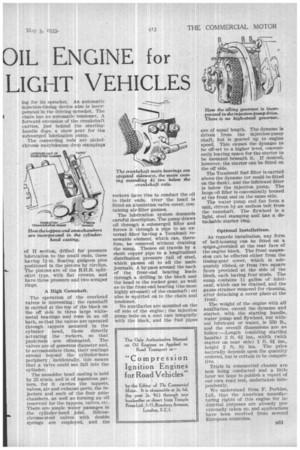

There are five main bearings, the upper half of each having a bronze shell, whilst the lower half has the white. metal run straight into the steel cap. The end and centre journals have each four studs, and the two intermediate bearings two studs. The block is robustly webbed at each bearing, with the bosses for the studs ribbed to the crankcase top.

Rigid Bearing Mountings.

All bearings are spigoted sideways (not endwise), as indicated in an accompanying sketch. The bearing at the flywheel end• is dowelled and takes the thrust. The• crankshaft has a diameter of 2i ins, and the big-ends 21 ins. Because of the hardness of the metal employed, cylinder liners are not fitted.

The front flanged portion of the main block forms a wide base for the aluminium timing-gear cover. .Inside this, a triple-roller chain drives a high camshaft and the injection pump (mounted on the near side), a minimum-speed governor being incorporated within the timing case and having an outboard bear ing for its sprocket. An automatic injection-timing device also is incorporated in the driving sprocket. The chain has an automatic tensioner. A forward extension of the crankshaft carries, just behind the startinghandle clogs, a skew gear for the submerged lubrication pump.

The connecting rods are nickelchrome molybdenum drop stampings of H section, drilled for pressure lubrication to the small 'ends, these having Ifin. floating gudgeon pins positioned in the pistons by circlips. The pistons are of the B.H.B. splitskirt type, with fiat crowns, and have three pressure and two scraper rings.

A High Camshaft.

The operation of the overhead valves is interesting; the camshaft is carried at the top of the block on the off side in three 'large whitemetal bearings and runs in an oil bath, so that the valves are operated through tappets mounted in the cylinder .head, these directly actuating the rockers, so that push-rods are eliminated. The valves are of generous diameter and, to accommodate them, their seatings extend beyond the cylinder-bore periphery ; incidentally, this means that a valve could not fall into the cylinder.

The monobloc head casting is held by 25 studs, and is of ingenious pattern, for it carries the tappets, valves, air and exhaust ports, the injectors and each of the four antechambers, as well as forming an oil reservoir for the tappets, valves, etc. There are ample water passages in the cylinder-head joint. Siliconchrome-steel valves with double springs are employed, and the rockers have ribs to conduct the oil to their ends. Over the head is fitted an aluminium valve cover, containing air-filter gauzes.

The lubrication system demands careful description. The pump draws oil through a submerged filter and forces it through a pipe to an external ;filter having a Tecalemit renewable element, which can, therefore, be removed without draining the sump. Thence oil travels by a short copper pipe to a longitudinal distribution pressure rail of steel, which passes oil to all the main journals. A by-pass around the back of the front-end bearing leads through a drilling in the block and the head to the rocker gear, as well as to the front-end bearing (the most highly stressed) of the camshaft ; oil also is squirted on to the chain and tensioner..

No auxiliaries are mounted on the off side of the engine; the injection pump beds on a seat cast integrally with the block, and the fuel pipes are of equal length. The dynamo is driven from the injection-pump shaft, but is geared up to engine speed. This causes the dynamo to be off-set to a higher level, conveniently leaving space for the starter to be mounted beneath it. If desired, however, the starter can be fitted on the off side.

The Tecalemit fuel filter is carried above the dynamo (or could be fitted on the dash), and the lubricant filter is below the injection pump. The large oil filler is conveniently housed at the front end on the same side. The water pump and fan form • a unit, driven by an endless belt from the camshaft. The flywheel is a light, steel stamping and has a detachable starter ring.

Optional Installations.

As regards installation, any form of bell-housing can be fitted on a spigot„provided at the rear face of the engine block. The front suspension can be effected either from the timing-gear cover, which is adequately ribbed, or from two square faces provided at the side of the block, each having four studs. The sump contains l gallon of lubricant, which can be drained, and the gauze strainer removed for cleaning, after detaching a cover plate at the front

The weight of the engine with all auxiliaries, except the dynamo and starter, with the starting handle, water pump and flywheel, but without lubricant or water, is 550 lb., and the overall dimensions are as follow :—Length (omitting :starting handle) 2 ft. 61 ins., width (with starter on new' side) 1 ft. 61 ins., height 2 ft. Oi ins. The price naturally depends upon the quantity ordered, but is certain to be competitive.

Trials in commercial chassis are now. being conducted and a little later we hope to publish a report of our own road test, undertaken independently.

We understand from F. Perkins, Ltd., that the American manufacturing rights of this engine for industrial purposes are already provisionally taken up, and applications have been received from several European countries.