KEEPING A PETROL-ELECT JS FLEET ON THE ROAD.

Page 16

Page 17

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

Details of the Efficient System of Overh; Ltd., for the Maintenance of their Large F which They Employ for Go

has been Developed by Thomas Tilling, ol-electric Vehicles and the Other Chassis .t and Private Hire Work.

(ANE OF the Most successful types of bus operat ing on the streets of London is the TillingStevens petrol-electric, which bas won the favour of the public, owing to its smooth starting, freedom from vibration and silent running. Apart from these points, it has proved highly efficient, has a long wearing life and is remarkably free from breakdowns ; in fact, we cannot remember ever having seen one of the Tilling-Stevens buses stopped involuntarily through mechanical or elecWeal defect,

Naturally, this has only been attained by paying the closest attention to maintenance, and during a recent visit to the overhauling works at Bull Yard, Peckham, S.E., we were afforded many proofs of the high quality of the workmanship and of the microscopic attention to detail by which the safety of the travelling public' is promoted. In order to meet the police requirements every bus is overhauled once a year, and every engine each six months, this also applying to the magneto. Each vehicle travels about 48,000 miles per year. The number of buses overhauled is about 30 per month, apartlfrom the other chassisto which we have already referred. In the overhauling use is made of the spare-unit system, and so rapidly can the work be carried out by this means that a chassis which we saw being stripped in the morning was alinost ready to leave the works in the evening, much of this efficiency being due to the untiring efforts and perspicacity of Mr. H. A. Ford, the works manager, who gave us every assistance.

We will now follow through the sequence of operations by which such remarkable results can be obtained. Immediately a chassiS arrives lathe body works, the water is drained from the radiator. It then enters the shops, and two men commence stripping, one from each end, and work towards the centre. First the seat is removed, c32

then the dashboard, after which the leads to the dynamo and motor are disconnected, the electrical boxes removed, the radiator, exhaust pipe and silencer unbolted, the dynamo and motor lifted out and the engine and axles removed for cleaning. The -main frame is then burnt over with a gas torch, which removes oil, etc., and allows the corners to.be examined for cracks and the tightness of all bolts to be tested. Close to the stripping shops are two chambers, In which the engines and axles are cleaned. These chambers are of an unusual type. Within them, on all sides, are water pipes equipped with spray nozzles, and through these hot water is passed at a fairly high pressure. In the case of the chamber for engines a little washing-soda and silicate are dissolved in the water, but in that used for the -axles the washing solution it hot caustic soda, as in this ease there is no fear of pitting any aluminium. There is a difference in the sprays, that for the engine being in large jets, whilst for re-moving mud from chassis parts the solution is in

• fine jets. Leading into and out of each chamber are rails, on which run two trollies ; by this means one trolley can be loaded while the other is within the chamber with its engine or axle, as the • case may be, undergoing cleaning, a process which takes about five minutes.

It is interesting to note that the old engine oil Is used for softening the dirt on engines and also for cleaning internal parts which, incidentally, are also run into the spray chamber. • Throughout the works are overhead runways equipped with lifting tackle • man-handling is thus reduced to a minimum, only small parts being carried by hand.

Cleanliness receives the utmosi-, consideration, and no dirt whatever is visible, except at the actual point where stripping takes place. Everywhere else neither dirt nor oil is to be seen, and tables, stools, trays, etc., are provided so that no part ,rests on the floor.

We have already pointed out that the frame, having received attention, passes direct to the erecting shop, and here the finished units are built into it, the original units proceeding via the runways for distribution to the various shops which deal with them, the order of reassembly being: Front axle, back axle, dynamo, motor, engine, radiator. The front aXles and rear axles are run Into position as units complete with springs, the frame being lifted by tackle for the purpose. In the case of the rear axle, this is complete with the rear springs, shackle brackets and crossbar, and the axle is rolled into position, the front spring pins inserted and the frame dropped on to the shackle brackets, which are 'then bolted into Position. • At this point we may mention that the motors

and dynamos are not overhauled at Peckham; but go to the Tilling-Sthvens works at Maidstone ; but the control and resistance boxes are dealt with at Peckham. Wheels and gearboxes, where the latter are used, go through the same process of cleaning as the axles, and then pass to their respective shops. All the bearings are re-white-metalled hi a special die-casting machine called a Monometer. This is a gas-heated cupola, in the pot of which is a plunger which forces the metal down and up into the bearing moulds. Incidentally, every type of bearing has its own mould. By this system

heating of the manta is uanecessary and a perfect cast is obtained.

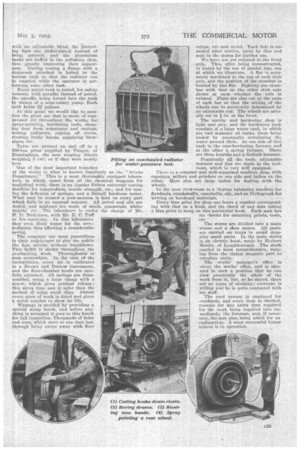

Very little time is wasted in bedding-in crankshafts ' and crankpins, the hearings being reamered to within a very small amount of the correct size, so that they require the minimum of scraping. For the main bearings an interesting conversion has been made of a Herbert turret lathe, the turret having been removed and replaced by a special rig for holding the crankcases and for supporting the bar carrying the reamers. By this means, all the main bearings are reamered out at the same time, and the bearings are kept in perfect alignment.

Crankshafts are reground when they are worn .002 in. to :OM in. oval or taper, this regrinding being standardized to .005 in. less than the previous standard, but this is required only after approximately 100,000 miles' running, i.e., about every two years. The bearings are then reamered out with reamers reduced to the same extent as the crankpins.

In the case of the cylinders, after these have worn to ,012 in. they are rebored to if in. above standard, and steel sleeves of 1-16 in. thickness pressed in to bring them back to the original size. These sleeves are made from heattreated steel tubes of 40-ton tensile strength, although castiron sleeves have been, used in some instances. This system of sleeve renewal has proved most advantageous, as it is found that aluminium pistons wear the cylinders much quicker than do these of cast-iron.

The gudgeon pins bear direct in the piston bosses, and in this case also it has been found that the gudgeon pins wear more rapidly than the pistons. There are two standards in'gudgeon pins, the piston bosses when worn being reamered 'out .91 in. larger, and, as an example, of economy, oversize gudgeon pins, when worn, are themselves . ground down' to the normal standard, for this purpose being carefully hardened in the first place to a depth of 1-16 in. Experiments are now being made with cast-aluminium One stub axle showing testing cylinders fitted with rig by which wheels are set and steel liners. These axle twist detected. are only half as

c.14 heavy as the normal pattern.

After reassembly the engines are started straight away under their own power, run for some hours light and well flooded with oil, and then tested against a Froude dynamometer. Every engine must produce 40 b.h.p. at 1,000 r.p.m. The test shop is remarkably quiet, and there is no smell of exhaust gases, these being taken through well-fitted tubes to pipes of 7 ins, diameter running along the floor and then up through the roof. Even with six or more engines running together there is practically no noise or vibration.

All magnetos are thoroughly overhauled and tested up to 1,500 r.p.m. and down to 60 r.p.m.

An interesting procedure is carried out in the case of thezear wheels. The brake drums of these, when worn, are bdred.out in a lathe, and spring-steel liners are riveted into posj.tion, these liners being cut to the exact length required and rolled into a circle, use being made of a pneumatic riveter, shielded to reduce noise, when the bands are in position. Where steel liners previously fitted have worn the rivets are cut out by a pneumatic chisel and a new band fitted. After riveting, the bands are skimmed out in a lathe.

Cracked wheels are arc-welded, as this localizes the heat and does not cause distortion.' All small weldi,ng jobs in aluminium are performed at the works, but heavier work is sent out.

The radiators are completely Stripped, a bracket secured to each tube block and the block lifted by tackle, carried along a runway and dropped into a hot

caustic-soda bath. It Is then washed in cold water and deposited on a stool above a grated drain: Here any defective tubes are replaced' and the header and bottom tanks are cleaned out and painted internally with a special preparation to prevent, corrosion and pitting. On reassembly; the whole radiator is filled with water and tested under 20 lb. pressure. Incidentally, ever y radiator is now fitted with an adjustable blind, the protecting bars are nickel-plated instead of beina' painted, and the aluminium tanks are buffed in the polishing shop, thus greatly improving their appearance. During testing a flange with a draincock attached is bolted to the bottom tank so that the radiator can he emptied while the operator is performing some other task.

Every petrol tank is tested, for safety reasons, with paraffin iustead of petrol, the paraffin being forced into the tank by means of a semi-rotary pump. Each tank holds 32 gallon-s.

At this point we would like to mention the great use that is made of cornpressed air throughout the works, for spray-painting, hardening tools, cleaning dust from armatures and casings, testing radiators, cutting off rivets, riveting brake bands, supplying blowpipes, etc.

Tyres are pressed on and oft in a 100-ton press supplied by Tangye, of Birmingham, the men treating wheels weighing 3 cwt. as if they were merely toys.

One of the most important branches of the works is what is known familiarly as the " Stinks Department." This is a most thoroughly equipped laboratory, in which, apart from all the chemical • reagents for analytical work, there is •an,Amsler Freres universal testing Machine for conipregSion, tensile strength, etc., and for testing the deflexion of springs,' and a Brinell hardness tester. What may be termed a post-mortem is held on every part Which fails in an unusual manner. All petrol and oils are teSted,,--and analyses are made of Steels, gunmetals, whitemetals, etc. The laboratarv is snider the charge of Isir. H. I) Nickinson, with Mr. E. C. TUff . as his -assistant. Ta this laboratory they even distil water for the accemulatcsrs, thus effecting, a considerable saving.

The company are most Punctilious in their endeavourS to give the public the best service without breakdown. This 'Spirit iS shown 'throughout the overhauling. work. Thoroughness is keen everywhere. In the case of the earburetters, every jet is calibrated in a Brown and Barlow instrument, and the float-chamber levels are carefully adjusted. All springs are disassembled, using a large clamp with a screw, which gives gradual release ; this save a time and is safer than the method of using small clips. Almost every piece of work is dated. and given a serial nuniber to show' its life.

• Wastage is avoided bk providing a special scrap -bench, and before anything is scrapped it goes to this bench for full inspection. Thousands of bolts and nuts, which were at. one time lost through .being swept away with floor

refuse, are now saved. Each bolt is an Denied after service, recut by dies and sent to the stores for further use.

We-have not yet referred to the front axle. This, -after being reconstructed, is tested by the use of special jigs, one of which we illustrate. A flat is accurately machined at the top of each stub axle, and the position of the crossbar is located by this fliit. Sighting one crossbar with that on the other stub axle

showsat once whether the axle is

twisted. Flats are also cut at the ends of each bar so that the setting of the wheels can be accurately determined by an adjustable rod. The wheels are actually set in it in. at the front.

The smithy and hardening shop is light and airy, and the hardening tank consists of a large water tank, in which are tw6 separate oil tanks, these being cooled by constantly circulating the water around them. At one side of thi;l tank is the case-hardening furnace and at the other a spring furnace. There are three hearths and a Goliath hammer. Practically all the tool, adjustable reamers and jigs are made in the toolroom, which is very well equipped.

There is a compact and well-organized machine shop, with capstans, millers andgrinders on one side and lathes on the other. Here also are large lathes for dealing with the wheels.

In the neat view-roam is a Norton balancing machine for flywheels, crankshafts, camshafts, etc., and an Etchograph for writing an hardened materials.

Every blue print for shop use bears a number corresponding with that on a hook, and the check of any uffin taking a blue print is hung on this particular honk. Each man has six checks for obtaining prints, taols, etc.

The stares are divided into a main stares and a shop stores. All parts

are carried on trays to avoid drop

ping small parts. In the main stores is an electrie hoist, made' by Herbert Morris. of I,,oughborough. The stock carried is most comprehensive, ranging from the tiniest magneto part to complete units.

The works' manager's office is above the works' office, and is sitn ated in such a position that he can view practically the whole of the work from it, but, as he stated, there -are no signs of slacking; everyone is willing and he is quite contented with his staff.

The card system _is employed for overhauls, and every item is checked, reasons for any extra time .required for the work being inquired into immediately, the foreman, and, if necessary, the men also, being asked for an explanation. A most suc.cessful bonus system is in operation.