Patents Completed.

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

A Two-stroke

Motor. Simplifying Silencing. Wrought and Welded Wheels.

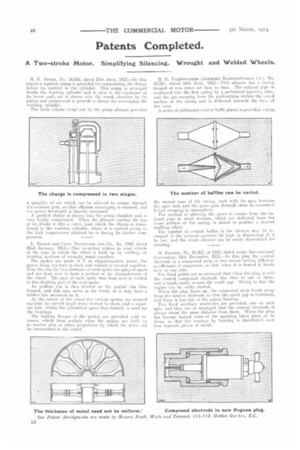

H. E. BEYER, No. 14,980, dated 30th June, 1913.—In this engine a separate pump is provided for compressing the charge before its ignition in the cylinder. This pump is arranged beside the working cylinder and is open to the crankcase at its lower end; air is drawn into the crank chamber by its piston and compressed to provide a charge for scavenging the working cylinder.

The extra volume swept out by the pump plunger provides a quantity of air which can be allowed to escape through the exhaust port, so that efficient scavenging is ensured, and the power developed is thereby increased. A gasified charge is drawn into the rump chamber and is very highly compressed. When the plunger reaches the top of its stroke it lifts a valve, past which the charge is transferred to the working cylinder, where it is ignited owing to the high temperature attained by it during its further COMpression.

L. BROWN and CHAS. MACINTOSH AND CO., No. 1760, dated 22nd January, 1913.—This invention relates to road wheels of the type in which the wheel is built up by welding, or riveting, sections of wrought metal together. The spokes are made of T or channel-section metal, the pieces being set back to back and welded or riveted together. Near the rim the two elements of each spoke are splayed apart and are bent over to form a portion of the circumference of the wheel. The part of each spoke thus bent over is welded to the abutting part of the next spoke. An endless rim is then riveted on the partial rim thus formed, and this may serve as the tread, or it may have a rubber tire mounted on it, At the centre of the wheel the various spokes are secured together by curved angle irons riveted to them, and P. separate hub, within the cylindrical space thus formed, is used for the bearings.

The butting flanges of the spokes are provided with recesses, which form sockets when the spokes are built up to receive pins or other projections by which the drive can be transmitted to the wheel.

H. G. FAIRWF.ATHER (AERmonE MANUFACTURII.s:G CO.; N'O. 13,931, dated 16th June, 1913.—This silencer has a casing formed of two cones set base to base. The exhaust pipe is continued into the first casing by a perforated tapering tube, and the gas escaping from the perforations strikes the coned surface of the casing and is .defiected towards the ba::e of the cone.

A series of perforated conical baffle plates is provided within the second cone of the casing, each with its apex towarns the open end, and the gases pass through these in succession lac fore escaping to atmosphere. The method of allowing the gases to escape from the exhaust pipe in small streams, which are deflected from the inner surface of the casing, is stated to produce a desired muffling effect. The number of conical baffles in the silencer may be increased if the exhaust pressure be high or diminished if it be low, and the whole silencer can be easily dismantled for cleaning.

Al, PoGsrom, No. 28,267, of 1913, dated under International Convention, 31st December, 1912.—In this plug the central electrode is a compound strip of two metals having different co-effirients of expansion, so that when it is heated it bends over to one side. The fixed points are so arranged that when the plug is coil the central compound electrode lies close to one of them, and a spark easily crosses the small gap. Owing to this the engine can be easily started. When the plug heats up, the compound strip 'bends away from the nearest electrode so that the spark gap is increased, and there is less risk of the points burning. Two fixed auxiliary electrodes are provided, one on each side, and they are so arranged that the central electrode is always aboutthe same distance from them. When the plug has become heated some of the sparking takes place on to these, so that the wastage by burning is distributed over four separate pieces of metal.