Castor Trailer in a New Producergas-plant Range A A NEW range

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

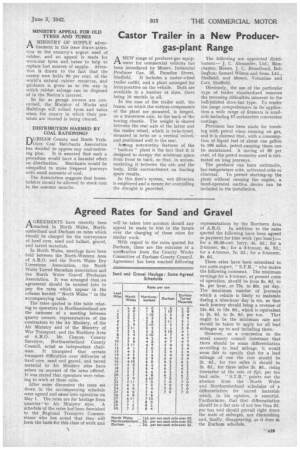

of producer-gas equipment for commercial vehicles has been introduced by Messrs. Industrial Producer Gas, 35, Paradise Street,

Sheffield, It includes a castor-wheel trailer outfit, and a plant arranged for Mom poration on the vehicle. Both are available in a number of sizes, there being 10 models in all.

In the case of the trailer unit, the frame, on which the various components of the plant are mounted, is hinged, on a transverse axis, to the back of the towing chassis, The weight is shared between the rear axle of the latter and the trailer wheel, which is twin-tyred, mounted in forks on a vertical swivel,and positioned well to the rear.

AtvOong noteworthy features of the "builtin " plant is the fact that it is designed to occupy the minimum space from front to back, so that, in accommodating it between the cab and the body, little encroachment on loading space results.

In this firm's system, wet filtration is employed and a means for controlling the draught is provided.

The following are appointed distributors:J. C. Alexander, Ltd.; Manchester; Messrs. J. C. Broadhead, Bollington; Samuel Wilson and Sons, Ltd.,_ Sheffield; and Messrs. Valantine and Carr, Sheffield.

Obviously, the use of the particular type of trailer standardized removes the reversing difficulties inherent to the ball-jointed draw-bar type. To render the range comprehensive in its' application a wide range of fitments is available including 57 carburetter conversion castings.

Provision has been made for boosting With petrol when running on gas, and it is claimed that, with a consumption of liquid fuel of about one gallon to 100 miles, petrol-running times can be maintained. A saving of 90 per cent. of the petrol economy used is estimated on long journeys.

The producer can burn anthracite, low-temperature coke, activated coke or

charcoal, To permit starting-up the plant without running the engine, a hand-operated suction device can be included in the installation.