A New Brake System for Trolleybuses

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

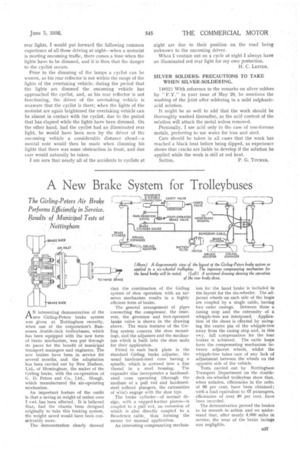

The Girling-Peters Air Brake Performs Efficiently in Service. Results of Mailkipal Tests at Nottingham

AN interesting demonstration of the new Girling-Peters brake system was given at Nottingham recently, when one of the corporation's Ransomes double-deck trolleybuses, which has been equipped with the new form of brake mechanism, was put through its paces for the benefit of municipal transport managers and engineers. The new brakes have been in service for several months, and the adaptation has been carried out by New Hudson, Ltd., of Birmingham, the maker of the Girling brake, with the co-operation of G, D. Peters and Co., Ltd., Slough, which manufactured the air-operating mechanism.

An important feature of the outfit is that a saving in weight of rather over 1 cwt. has been effected, It is believed that, had the chassis been designed originally to take this braking system, the weight saved would have been considerably more.

The . demonstration clearly showed

that the combination of the Girling system of shoe operation with an airservo mechanism results in a highly efficient form of brake.

The general arrangement of pipes connecting the compressor, the reservoir, the governor and foot-operated brake valve is shown in the drawing above. The main features of the Girling system concern the shoe mountings, and the adjusters and the mechanism which is built into the shoe units for their application, Fitted to each back plate is the standard Girling brake adjuster, the usual hardened-steel cone having a spindle, which is screwed into a fine thread in a steel housing. The expander also incorporates a hardenedsteel cone operating •(through the medium of a pull rod and hardenedsteel rollers) plungers, the extremities of which engage with the shoe tips.

The brake cylinder—of normal design, with a cupped-leather piston—is coupled to a pull rod, an extension of -which is also directly coupled to a Bowdenex cable, thus forming the means for manual application.

An interesting compensating mechan lain for the hand brake is included in the layout for the six-wheeler. The adjacent wheels on each side of the bogie are coupled by a single cable, having two outer casings. Between these a casing stop and the extremity of a whipple-tree are interposed. .Application of the shoes' is effected by swinging the centre pin of the whipple-tree away from the casing stop and, in this voLy, full compensation for the four brakes is achieved. The cable loops form the compensating mechanism between adjacent wheels, whilst the whipple-tree takes care of any lack of adjustment between the wheels on the opposite side of the vehicle.

Tests carried out by Nottingham Transport Department on the doubledeck six-wheeled trolleybus show that, when unladen, efficiencies in the circle:: of 60 per cent, have been obtained ; with a load equivalent to 67 passengers, efficiencies of over 40 per cent. have been recorded,

The demonstration.proved the brakes to be smooth in action and we understand that, after nearly 4,000 miles in service, the wear of the brake facings was negligible.