A FAST 3-TONNER

Page 32

Page 33

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

the Latest Fordson ON TRIAL

A 50-cwt. Lorry Guaranteed to Carry 4 tons. Attractive Features Include a Highly Efficient 81 b.h.p. V-eight Engine, Improved Brakes, Comfort for Driver and Low

First Cost

ARUN of 80 mil e-6 on one of the latest Fordson 3-tonners and a close examination of the chassis and equipment of this vehicle, have left us much impressed by the excellence of its general performance and by the many clever and practical features it incorporates.

All our standardized special tests were carried out during the trial, and none revealed any fault of consequence. The machine submitted to us had the shorter of the two wheelbases offered and the higher of the two optional axle ratios.

Readers will remember that the 3ton model was introduced at the Ford Exhibition in October last. It did not come into production, however, until this year. Although rated for 3-ton loads, it is covered by a guarantee up to a maximum of 4i tons. Even with the longer wheelbase, the unladen weight is only 2 tons 31 cwt., so the vehicle ranks among the leaders in the highcapacity, low-weight, 30-mph. class, How Weight is Saved.

In considering how weight has been saved, it must be remembered that the designers started with a big lead, because the V-type eightcylindered power unit, by reason of its layout and characteristics, is much lighter than a " four," " six " or " eight in line " of similar capacity. The two-bank one-piece cylinder casting economizes in weight, the crankshaft is short, and a large mass of metal is avoided on account of the lightness of the flywheel. Moreover, indirect weight saving results, in a number of ways, from the low overall length of the engine.

• It has always been Ford practice to employ materials of the first quality practicable. No exception to the rule has been made in the case of the vehicle under consideration. Welding is widely used in the construction of the chassis, whilst parts, which formerly would probably have been made of malleable iron, are now alloy-steel forgings or pressings. The well-known Ford triangulated radius-rod system is embodied on the 3-tonner, both front and rear axles being thus positively located. The two ball-ends of the four rods are socketed to a pair of sturdy crossmembers, one located behind the gearbox and the other about amid ships. These are respectively 12i ins. and 81 ins. deep.

The rear springs are 50 ins, long, and have, above them, built-in helper springs. They are shackled at both ends, being called upon to locate the axle only in respect of lateral tendencies.

At the front there is a new suspension feature, the transverse spring being mounted several inches forward of the axle, where it is shackled to extensions of the radius rods. The arrangement allows the engine to be positioned nearly 9 ins. farther forwards than in the earlier design. By this means, and without increasing the wheelbase, the body and cab have been lengthened.

Another new feature is a centrifugally assisted clutch. It is obvious that it is desirable to use, in a clutch, springs of the minimum strength. In this way the withdrawal mechanism is lightly stressed and the pedal pres sure required is moderate. They must, however, be strong enough to prevent slip at maximum torque, and this is .the limiting factor.

The Ford concern takes advantage of the fact that maximum torque is exerted at only fairly high revolutions, and uses bob-.weights, under the influence of centrifugal force, to amplify the spring pressure as engine speed rises.

To obtain a demonstration of the manner in which these weights function, we held the clutch out with the gear lever in the neutral position, the vehicle being stationary, and then speeded up the engine. The pedal at once came up against our foot pressure. Indeed, at high "revs.," the force it exerted was practically irresistible by the leg muscles.

This experiment we performed as an auxiliary to our stop-and-restart test, which we thought might reveal some unexpected drawback to the centrifugal device. However, our suspicions were groundless, for no fault was brought to light and a faultless restart, on a 1 in 6 gradient, was made in bottom gear with complete ease.

It will be observed, from the accompanying specification table, that second, third and top ratios are fairly close, whilst first is a big step " down." This enables full advantage to be taken of the capabilities of the engine over a wide variety of normal road conditions, yet provides a gear for exceptional circumstances. It would probably suffice for a start, up a 1-in-3 slope.

Starting in First Gear.

It has the additional advantage of discouraging drivers from attempting to start up hills in second gear, which we essayed to do, having succeeded so easily in first gear, and failed.

For a straight non-stop climb, we took the Fordson to Brockley Hill, near Edgware, on which we have timed numerous vehicles. This acclivity terminates with a i-mile of about 1 in 8, approached by a steady slope which precludes " rushing " the ascent. In this case the approach brought our speed down to 22 m.p.h. in third gear.

The steep portion eventually neces sitated second gear, but the speedometer needle never fell appreciably below 8 m.p.h. and began to mount the scale again before the summit was reached. The i-mile was covered in 46 secs., which is 4 secs. less time than we have yet taken for this climb with 3 tons of pay-load on board. Referring to our test, in November last, of the Fordson eightcylinder 2-tonner, we find the figure for this machine was 30 secs.

Knowing the liking the Ford engine has for " revs.," we were favourably surprised to observe the manner in which it " hung on " when negotiating Brockley Hill.

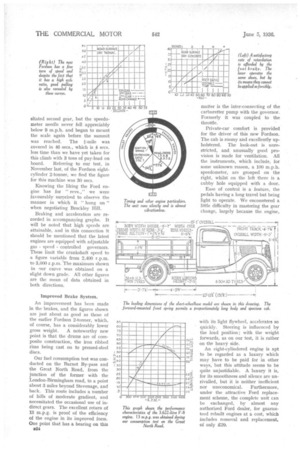

Braking and acceleration are recorded in accompanying graphs. It will be noted that high speeds are attainable, and in this connection it should be mentioned that the latest engines are equipped with adjustable gas speed controlled governors. These limit the crankshaft speed to a figure variable from 2,400 r.p.m. to 3,000 r.p.m..The maximum shown in our curve was obtained on a slight down grade. All other figures are the mean of data obtained in both directions.

Improved Brake System.

An improvement has been made in the brakes, and the figures shown are just about as good as those of the earlier Fordson 2-tonner, which, of course, has a considerably lower gross weight. A noteworthy new point is that the drums are of composite construction, the iron ribbed rims being cast on to pressed-steel discs.

Our fuel consumption test was conducted on the Barnet By-pass and the Great North Road, from the junction of the former with the London-Birmingham road, to a point about 3 miles beyond Stevenage, and back. This route includes a number of hills of moderate gradient, and necessitated the occasional use of indirect gears. The excellent return of 13 m.p.g. is proof of the efficiency of the engine in its improved form. One point that has a bearing on this B24 matter is the inter-connecting of the carburetter pump with the governor. Formerly it was coupled to the throttle.

Private-car comfort is provided for the driver of this new Fordson. The cab is roomy and excellently upholstered. The look-out is unrestricted, and unusually good provision is made for ventilation. All the instruments, which include, for some unknown reason, a 100 m.p.h. speedometer, are grouped on the right, whilst on the left there is a cubby hole equipped with a door.

Ease of control is a feature, the pedals having a long travel but being light to operate. We encountered a little difficulty in mastering the gear change, largely because the engine,

with its light flywheel, accelerates so quickly. Steering is influenced by the load position ; with the weight forwards, as on our test, it is rather on the heavy side.

An eight-cylindered engine is apt to be regarded as a luxury which may have to be paid for in other ways, but this attitude seems to be quite unjustifiable. A luxury it is, for its smoothness and silence are unrivalled, but it is neither inefficient nor uneconomical. Furthermore, under the attractive Ford replacement scheme, the complete unit can be exchanged, by almost any authorized Ford dealer, for guaranteed rebuilt engines at a cost, which includes removal and replacement, of only £20.