The Automatic Choice

Page 64

Page 65

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

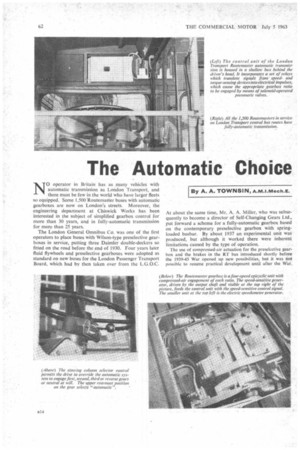

By A. A. TOWNSIN, N. 0 operator in Britain has as many vehicles with automatic transmission as London Transport, and there must be few in the world who have larger fleets so equipped. Some 1,500 Routemaster buses with automatic gearboxes are now on London's streets. Moreover, the engineering department at Chiswick Works has been interested in the subject of simplified gearbox control for more than 30 years, and in fully-automatic transmission for more than 25 years.

The London General Omnibus Co. was one of the first operators to place buses with Wilson-type preselective gearboxes in service, putting three Daimler double-deckers so fitted on the road before the end of 1930. Four years later fluid flywheels and preselective gearboxes were adopted as standard on new buses for the London Passenger Transport Board, which had by then taken over from the L.G.O.C. At about the same time, Mr. A. A. Miller, who was subsequently to become a director of Self-Changing Gears Ltd., put forward a scheme for a fully-automatic gearbox based on the contemporary preselective gearbox with springloaded busbar. By about 1937 an experimental unit was produced, but although it worked there were inherent limitations caused by the type of operation.

The use of compressed-air actuation for the preselective gearbox and the brakes in the RT bus introduced shortly before the 1939-45 War opened up new possibilities, but it was not possible to resume practical development until after the War. At this time, L.T. was iTterested in hydraulic operation for the brakes and gearbox mid experimental installations of this kind were made with RT type buses, the last being put into service in 1951. The geatboxe,s were of the direct-selection type employing individua internal operating cylinders for each gear, in a like manne to that applying to direct-selection gearboxes using compresse air.

The use of individual op rating cylinders for the gears which can provide continuous-tra tion gear-changes lent itself to the application of automatic c ntrol. The hydraulically-operated gearbox was found to pe it finer and more consistent control of the take-up of the driv during gear changes, an important merit in an automatic gear ox when the driver cannot "help " the process by timing his actions to avoid any tendency to jerkiness. However, in c njunction with the manufacturers, it was decided to standar ize on the air-operated version as this was widely accepted bv other operators and more readily available. Although the first four prototype Routemasters originally had hydraulically-operated gearboxes, of which all but the first were of the fully-automatic type, the production models have air-operated gearboxes. Except for a batch of vehicles which are equipped as coaches for operation on Green Line routes, all are fully automatic.

The decision to adopt automatic gearboxes for the production Routemasters came during the period when the prototype vehicles were in experimental service. Results with the latter had been encouraging and the ease of driving had an added attraction because more than 1,000 Routemasters were to be used on lrolleybus replacement duties. Drivers are trained to drive on RT buses with preselective gearboxes, but those who are to handle .Routemasters for the first time, whether new or already driving older buses, go through an additional brief training programme.

Development of the automatic gearbox continued during the period when the process of preparing the Routemaster for production was in hand. The automatic control system, developed jointly by London Transport with C.A.V. Ltd. and Self-Changing Gears Ltd. is electro-pneumatic, with a speedsensitive generator driven by the gearbox output shaft, and a torque-sensitive switch jointly determining the ratio engaged. The torque-sensitive switch is incorporated in the accelerator linkage and gives three gear-change ranges, the choice of which is determined by accelerator-pedal position. The output of the speed-sensitive generator is arranged to make the system engage higher gears as the road speed rises, whereas increasing pressure on the accelerator tends to delay upward changes. The combined effect decides the actual ratio engaged at any instant.

Determining the settings for the speeds at which gear-changes occul. was carried out by a process of discussion, estimate, practical test and, where necessary, further adjustment. Factors

influencing the choice of these speeds included the effect on performance and fuel consumption as well as the effect on noise-level and any tendency to " fussiness " in running.

A similar procedure was adopted with the setting of the gearbox to obtain smooth gear changes. The London Transport engineers consider that continuous traction during gear changes is vital to an automatic gearbox. On the Routemaster application, as on others of similar basic design, this is achieved by arranging for the drive through the " new" ratio to be engaged gradually, the process commencing before the " old " ratio is completely dropped. As each ratio is engaged by a brake band or, in the case of top gear, a friction plate clutch, in a Wilsontype gearbox, this feature is achieved by restrictors or air jets in the air-supply circuits which have the effect of slowing the take-up process. The sizes of restrietors, coupled with the setting ofthe brake bands themselves, have a marked effect on the smoothness of change, quite small alterations being sufficient to make an appreciable difference to the performance.

Although work is still proceeding on the optimum settings. standardized settings are used in production. The gearboxes, manufactured together with the remainder of the vehicles' running gear by A.E.C. Ltd., are inspected and tested before delivery, their performance being checked by means of instruments. In general, no departure from the standardized settings is made, the aim being to preserve complete unit interchangeability.

A noteworthy adjunct to this is that it has been found necessary to ensure that the relationship between acceleratorpedal position and injection-pump output is consistent between vehicles and that calibration of the injection pumps themselves is uniform. This is because the torque-sensitive signal to the automatic-gearbox control mechanism is derived from the position of the accelerator linkage, which is roughly proportional to the torque developed. Variations in linkages between chassis that would be quite acceptable on vehicles having nonautomatic transmission, and probably barely perceptible to the driver, can appreciably upset the automatic-gearbox response.

The first production Routemasters were placed in service during 1959 and routine gearbox overhaul work is now just commencing. No noticeable departure from the high standards of durability obtained from epieyelic gearboxes of the preselettive variety has been noted. Apart from a few random failures of a similar kind to those normally anticipated in large production runs, no gearbox defects of a serious nature have become evident. In particular, no evidence of excessive wear or damage owing to the effects of automatic operation has materialized.

Comparisons of fuel consumption are slightly influenced by the fact that the standard Routemaster is 5 cwt. lighter than a standard RT. although the increased seating capacity, 64 against 56, probably makes the average running weight very similar. I understand that the fuel consumption figures are almost identical and that the automatic transmission has shown no tendency to worsen them.

My own observations of vehicles in service indicate that drivers generally allow the automatic system to operate continuously. The control lever on the steering column allows manual selection of first, second or third gears, as well as reverse, the "automatic" position taking the place of fourth gear. The intention is that the non-automatic positions should be used only when conditions make them necessary, notably for restarting on or descending a fairly steep hill. When the automatic circuits are in use, starting from rest takes place in second gear, this also being recommended London Transport practice for buses with preseIective transmission.

A small number of drivers evidently prefer to select their own gears even in normal driving, but in my experience the results are usually inferior to those using !` automatic" so • far as smoothness of ride for the passengers is concerned, Individual buseS vary slightly, but my impression is that the standard of gear-changing is a little better than that of an average driver with a preselective-gearbox bus, very much better than that of a clumsy driver, but not usually yet quite equal to that of a skilled driver taking care with his. gearchanging.

A marked improvement has been noticeable during the past year or -so since the automatic mechanism has been modified to have second gear engaged when the vehicle is at rest with the selector lever in the "automatic " position. Previously it had been arranged to select neutral as the vehicle rolled to rest, engagement -of second gear for moving off-not occurring until the accelerator was pressed. In some cases this, gave satisfactory results, but sometimes the engine speed had begun to rise before the gear engaged, with the effect that the take'-up' of drive was occurring by slipping the gearbox brake bands rather than by using the fluid flywheel. The resulting take-off was generally not as imooth as would normally be associated with a fluid flywheel. Starting from test is now completely smooth, although the previous system's advantage of idling in neutral and the slight fuel saving this gave have been lost unless the driver deliberately selects neutral. The upward change from second to third gear varies slightly in "quality ", some buses giving a slightly jerky change, whilst others are quite satisfactory The change into top gear, which involves the engagement of a multi-disc clutch rather than the use of a toggle-action brake-hand mechanism, is in my experience invariably smooth.

To sum up, London Transport's experience of automatic transmission has been encouraging and fully justifies the decision to adopt it. I am Indebted for assistance in compiling, this article to Mr. A. A. M. Durrant, Chief Mechanical Engineer (Road Services) of London Transport.