THE NEW RELIANT Three

Page 38

Page 39

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

vheeler

PUT THROUGH [TS PACES

INTRODUCED some two months ago, the Reliant three-wheeled van has been built to provide efficient and economical transport of loads up to 7 cwt. To this end, simplicity of design and ease of maintenance are features which have received special attention, and for these reasons a single-cylindered power unit is used.

That the J.A.P. single-Cylindered air-cooled engine is well equal to the work imposed upon it was evidenced during the course of our recent road test of the machine in the Midlands, when, despite extremely sultry weather, no signs of overheating or distress were apparent.

Rated at 4.5 the power unit has a capacity of 600 cc., and develops a maximum of 15 b.h.p. at 3,500 r.p.m. The cylinder head is detachable, and the side valves are fully enclosed, an easily removable cover providing for tappet adjustment. Dry-sump lubrication is employed, the oil tank, which has a capacity of gallon, being mounted in an accessible position on the near side of the frame. Ignition is by the coiland-battery System, and the dynamo is mounted transversely behind the engine, being driven by a belt therefrom.

Substantial Frame Bracing.

The driver sits astride the engine, which is enclosed by a light metal cover, the channel member supporting this cowling forming a strong bracing between the centre, tubular cross-member of the frame and the steering head.

A point worthy of cornmelf is the sturdy construction of the frame, the two deep-side members being up

swept at the front and attached to a large-diameter tubular member, on which the steering head is mounted. Both at the forward and rear ends of the main frame, channel crossmembers are used to ensure rigidity, the forward member providing the front engine mounting.

There is little doubt that this careful attention to frame stiffness is largely responsible for the good roadholding characteristics that we noted during our test-"--over a distance of some 10 miles.

Transmission is by single-roller chain to a Burman three-speed-and reverse gearbox, the chain being enclosed and provided with a means for lubrication. A shock-absorbing device is incorporated in the multiplate clutch, which is pedal operated,

and the final dnve is by means of a heavy twin-roller chain.

The rear chain returns over a jockey , sprocket mounted on ball bearings, the triangular cradle bearing the sprocket, being carried on a bracket attached to the central tubular cross-member. A rod, attached to the topmost point of the cradle, is proj( cted forward to a point beneath the bonnet, and movement of the cradle by means of a wing-nut provides for adjustment of the rear driving chain.

Of the semi-floating type, the rear axle incorporates a bevel-type differential and a shock-absorbing device for the final drive. The shafts are of large diameter and run on roller bearings.

Steering is effected by a centrally mounted wheel, the steering box at the base of the short column being connected to the steering head by a drag link.

The single front wheel is mounted in a motorcycle type front fork, suspension being effected by a helical spring with a friction damper.

Interconnected Brakes.

Internal expanding brakes are provided on all three wheels, the front shoes being operated by cable, and the rear brakes by rods. Both pedal and hand lever are interconnected, and a simple wing-nut adjustment is used for the foot and hand brakes. In addition, separate adjustment is provided for each pair of shoes, A separate steel sub-frame forms the basis of the body. This frame is dropped forward of the rear axle, and at its front end has vertical pillars so that at this point the body is carried on two large bearings mounted at the top of each chassis side member.

At the rear the body is carried directly on the friction-type shock absorbers which are incorporated in the shackles of the quarter-elliptic springs. These springs are of the progressive type. •

On taking over the machine for our test, we noted that the engine started easily on depression of the kick-starter, which is located in a convenient position behind the driver's footboard on the off side and within the body. In order to ensure easy starting in cold weather a mixture control is provided and is operated by a knurled nut which projects through the engine cover.

We proceeded to try out the vehicle on a steep gradient, and for this purpose sought Boot Hill, in the village of Grendon. This climb is f-mile in length and has a maximum gradient in the order of I in 8.

Good Getaway on a Gradient.

On our first ascent the machine was badly baulked by a lorry on one of -the bends, this necessitating a stop and giving us an opportunity to test the getaway of the machine on the gradient. The powerful hand brake held the laden van with ease, whilst we found the lever conveniently placed to enable a clean restart to be made. The clutch took up the drive quite smoothly. A second ascent of the hill proved that there was ample power

available,. and on the. steepest section the minimum speed registered was 9 m.p.h. in second gear. On the descent of the hill both hand and foot brakes were found capable of holding the machine on the 'steepest part of the decline.

Proceeding to the Tamworth-Lichfield road for our acceleration and braking tests, an ascent was made of Spon Lane, Polesworth. This acclivity is quite short, but near the top has a gradient in the nature of

in 61. The machine successfully negotiated this climb in second gear, the minimum speed for a few yards being 8 m.p.h.

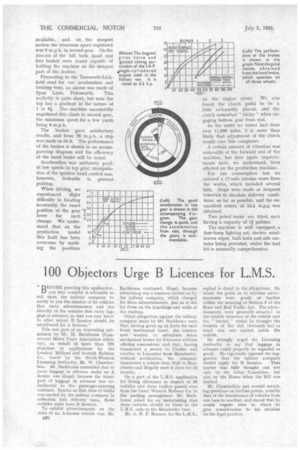

The brakes gave satisfactory results, and from 20 m.p.h. a stop was made in 28 ft. The performance of the brakes is shown in an accompanying diagram and the efficiency of the hand brake will be noted.

Acceleration was uniformly good: at low speeds in top gear, manipulation of the ignition hand control was, however, desirable to prevent pinking.

When driving, we experienced . slight difficulty in locating accurately the exact position of the gear lever for each change. We understand that on the production model this fault has been overcome by marking the positions

(Left) The performance of the brakes is shown in the graph. Note the good results obtained from the hand brake, which operates on.

all three wheels.

on the engine cover. We also found the clutch pedal to be a little awkwardly placed, and the clutch somewhat " sticky " when engaging bottom gear from rest.

As the outfit we tested had done over 11,000 miles, it is more than. likely that adjustment of the clutch would cure this complaint.

A certain amount of vibration was noticeable at the forward end of the machine, but here again improve ments" have, we understand, been effected on the production machine.

For our consumption test we covered a 17-mile circular route from the works, which included several hills. Stops were made at frequent intervals to simulate delivery conditions, so far as possible, and the exexcellent return of 54.4 m.p.g. was obtained.

Two petrol tanks are fitted, each having a capacity of l gallons.

The machine is well equipped, a four-lamp lighting set, electric windscreen wiper, bulb horn and side curtains being provided, whilst the tool kit is unusually comprehensive.