A New Rotary Oil Pump

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

High Efficiency and Variable Discharge. Features. of Interesting Fluvario Device

A NEW type of oil-pump, capable IA. of developing high pressures and with an output which can be varied while the pump is in operation, is being, manufactured by the Fluvario Co., a concern of hydraulic engineers, Sedgley Road West, Tipton, Stalls. It is valveless and provide's far an almost straight-throughflow, so that the power loss due to turbulence is negligible. In addition, the frictional losses are exceptionally small and the efficiency of the pump is stated to be particularly high. This pump is, so to speak, a -by-product from the development of a variable-ratio hydraulic transmission, which we hope to describe shortly.

In a Fluvario pump of normal external dimensions, the maximum pressure developed is 300 lb. per sq. in., and it is understood that with slight modifications of design this can be increased to 1,000 lb. per sq. in., if such a pressure be required. The normal pump, however,operates best at pressures between zero and, say, 120 lb. per sq. in. At 1,900 r.p.m. its output is 4.3 g.p.m,, against a pressure of '2.5 lb. per sq. in. At 100 lb. per sq. in. the delivery is :3.85 g.p.in., whilst the device will suck from a depth of 30 ft. or more.

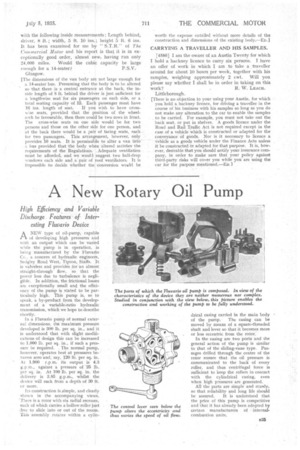

Its construction is simple, and clearly . 'shown in the accompanying views. ' There is a rotor with six radial recesses, each of which carries a hollow roller just ,free to slide into or out of the recess. This assembly rotates within a cylin drical casing carried in the main body of the pump.The casing can be moved by means of a square-threaded shaft and lever so that it becomes more or less eccentric from the rotor.

In the casing are two ports and the general action of the pump is similar to that of the sliding-vane type. Passages drilled through the centre of the rotor ensure that the oil pressure is communicated to the back of every roller, and thus centrifugal force is sufficient to keep the rollers in contact with the cylindrical casing, even when high pressures are generated.

All the parts are simple and sturdy, so that. reliability and long life should be assured. It is understood that the price of this pump is competitive and that it has already been adopted by certain manufacturers of internalcombustion units.