POINTERS IN BRAKE MAINTENANCE.

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

Important Advice and Useful Hints and Tips for the Engineer and Repairer When Overhauling Brakes and Brake Mechanism.

AYING regard to the interest recently shown in the subject of brake maintenance, a few practical notes on the subject may be welcomed by those who wish to keep their brakes as perfect as the present designs. of this component will permit.

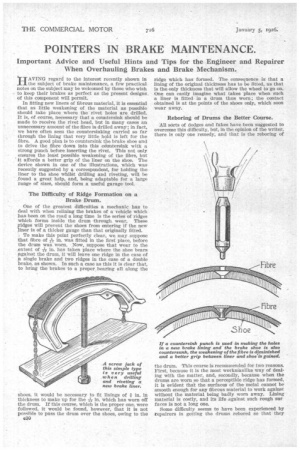

In fitting new liners of fibrous material, it is essential that as little weakening of the material as possible should take place where the rivet holes are drilled. It is, of course, necessary that a countersink should be made to receive the rivet head, but in many cases an unnecessary amount of the fibre is drilled away; in fact, we have often seen the countersinking carried so far through the lining that very little bold is left for the fibre. A good plan is to countersink tie brake shoe and to drive the fibre down into this countersink with a strong punch before inserting the rivet. This not only ensures the least possible weakening of the fibre, but It affords a better grip of the liner on the shoe. The device shown in one of the illustrations, which was recently suggested by a correspondent, for holding the liner to the shoe whilst drilling and riveting, will be found a great help, and, being adaptable for a large range of sizes, should form a useful garage tool.

The Difficulty of Ridge Formation on a Brake Drum.

One of the greatest difficulties a mechanic has to deal with when relining the brakes of a vehicle which has been on the road a long time is the series of ridges which forms inside the drum through wear. These ridges will prevent the shoes from entering if the new liner is of a thicker gauge than that originally fitted.

= To make this point perfectly clear, we may suppose that fibre of•a=, in. was fitted in the first place, before the drum was worn. Now, suppose that wear to the ,extent of 1.1-c in. has taken place where the shoe bears against the drum, it will leave one ridge in the case of n single brake and two ridges in the case of a double brake, as shown. In such a case as this it is clear that, to bring the brakes to a proper bearing all along the

shoes, it would be necessary to fit linings of in. in thickness to make up for the -Ain. which has worn off the drum. If this course, which is the proper one were followed, it would be found, however, that it is not possible to pass the drum over the shoes, owing to the 4g34)

ridge which has formed. The consequence is that a lining of the original thickness has to be fitted, as that is the only thickness that will allow the wheel to go on. One can easily imagine what takes place when such a liner is fitted in a drum thus worn; the contact obtained is at the points of the shoes only, which soon wear away.

Reboring of Drums the Better Course.

All sorts of dodges and fakes have been suggested to overcome this difficulty, but, in the opinion of the writer, there is only one remedy, and that is the reboring of

the drum. This course is recommended for two reasons. First, because it is the most workmanlike way of dealing with the matter, and, secondly, because when the drums are worn 80 that a perceptible ridge has formed, it is evident that the surfaces of the metal cannot be smooth enough for any fibrous material to work against without the material being badly worn away. Lining material is costly, and its life against such rough sur faces is not a long one.

Some difficulty seems to have been experienced by repairers in getting the drums rebored so that they

are given a smooth surface. This is probably due to their having had the job done in some small engineer's shop which is not properly equipped for such a job and that a lathe which was not rigid enough has been used to bore the drums. No more difficulty should be experienced in reboring a drum than in boring it in the first place. A good tip for those who are reboring such drums is to have a piece of shafting between the centres whilst the boring goes on, as this steadies a lathe and prevents chattering.

An example of the poor attention that is given to brake maintenance by some owners is shown in a photograph, reproduced in this page, of a section cut from the drum of a two-ton American lorry, which, as Gan be seen, measures exactly 1,-32 in. in thickness. This drum had an expanding brake inside it and a band brake acting on the outer side.

Towards the end of the period of service of this drum it was found that neither of the brakes would net if applied singly, as in that case it only distorted the drum, but when both brakes were applied together they were more or less effective, although a great risk was being run.

Making Allowance for Bearing Wear wnen Adjusting the Brakes.

In those cases where a plain bearing and floating bush are used, it is essential, when adjusting brakes, that great care should be taken to give full consideration to the matter of allowance for the wear in the bearing. If the bearing is in good order and there is no undue wear or play between the wheel and the axle sleeve, the adjustment of a brake is a simple matter ; but should there be perceptible play, extra care should be taken in the adjustment of the brakes. It is obvious, if there is appreciable wear at this part, that the weight of the vehicle, resting, as it does, on its axle, will bring the axle to the lowest part of the bore of the hub. In other words, the axle will be eccentric with the wheel and drum. Now, the flange on which the brakes are mounted was designed for a drum that was originally concentric with the axle; consequently, when new linings are fitted to such a vehicle and adjusted to what appears to be the correct degree, the liners will only be bearing on the drum at the lowest part, owing to the eccentricity caused by wear. When such brakes are • applied with full force, they will often be found to lift the chassis bodily in their effort to centralize themselves.

The Error of Jacking-up when Adjusting Brakes.

The only real method of dealing with such a case is to have a new bush fitted to the wheel. Such dodges as jacking up the axle whilst adjusting the brakes cannot be too strongly condemned.

When overhauling or examining brakes, it is as well to look to certain parts, for the fact that any of them failed might be just as dangerous as if the brakes themselves failed. The nuts which secure the wheel from coming off the axle tube should be carefully examined to see that the fine thread which is usually cut upon them is in good condition. If any sign is detected of such threads stripping on either the sleeve or the nut, matters should be put right immediately. Should these nuts give way, it may cause a very serious accident. Another point to examine is-the means for preventing oil from escaping into the brake drum from the axle bearing. Whatever arrangement is provided by tile maker should be carefully inspected, and, if found in any way defective, it should be seen to at once, as a leakage of oil at this place may cause a brake failure.

It does not seem that sufficient margin is allowed in many designs of brake for the expansion of the drums through heat, where internal shoes are used. It does not seem to be generally known that experiments have proved that, if a brake is applied and the vehicle is run with it on for several miles, the drum will expand to an extent that will render the brake useless, yet with the brake notched up, it has returned to its full efficiency when a hose was played on the drums to cool them and bring them back to their original diameter.

The lesson gained from this experiment is that a larger margin than is generally recognized is needed to allow the brake shoes to follow the expansion of a drum when in use on a long and steep hill with a heavy load on the vehicle.