HOW UNDERTYPE STEAM ONS COULD BE IMPROVED.

Page 16

Page 17

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

FOLLOWING the article dealing with overtype steam wagons, published in the issue • of The

Commercial Motor for April 10th, 1923, the object of the present article is to criticise present designs of undertype steam wagons and to offer suggestions for possible improvements. The undertype wagon was originally produced in France, and was manufactured by,many makers in this country, notably Messrs. Leyland, Thornycroft, Straker, Coillthard, Mann, Yorkshire, and Sentinel. Until recent years the only undertype wagons still being produced were the Sentinel and the Leyland ; all Ole other makers had either abandoned the manufarture of steam wagons or had transferred their attentions to the overtype design, a notable exelep tion being t h e makers of t h o Yorkshire-a vehicle of a singuiarly distinctive type.

Many m 0 r 0 makers are no-0 producing undertype wagons; some are new firms entering the lists, and a few P.s.oi ler a r e previous makers of -over

type wagons. hi

the meantime, the Sentinel and Leyland wagons have been considerably improved.

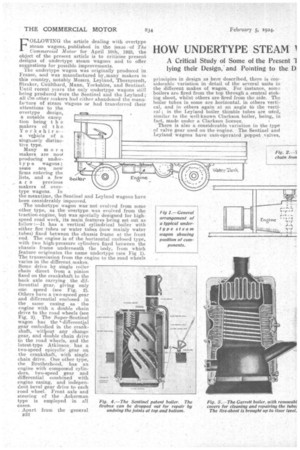

The undertype wagon wasnot evolved from some other type, as the overtype was evolved from the traction-engine, but was specially designedfor highspeed road work, its main features being set out as follow :—It has a vertical cylindrical boiler with either fire tubes or water tubes (now mainly water tubes) fixed between the chassis frame at. the front end. The engine is of the horizontal enclosed type, with two high-pressure cylinders fixed between the chassis frame underneath the body, from which feature originates the name undertype (see Fig 1). The transmission from the engine to the road wheels varies in the different makes. Some drive by single roller Chain direct from a pinion fixed on the crankshaft to the back axle carrying the differential gear, giving only one speed (see Fig. 2). Others have a two-speed gear and differential enclosed in the same casing as • the engine with a double chain drive to the road wheels (see Fig. 3). The Super-Sentinel wagon has the "-differential gear embodied in the crankshaft, • wittou.t, any change gear, and double chain drive to the road. wheels, and the latest-type Atkinson: has a two-speed epicyclic -gear on the crankshaft, with single chain drive. One other type, the Brotherhood, has an engine with compound cylinders, two-speed gear and differential combined with engine casing, and independent bevel gear drive to each road wheel. Front axle and steering of the Ackerman type: is employed in all cases.

. Apart from the general )332

principles in design as heredescribed, there is considerable variation in detail of the several units in the different makes of wagon. For instance, some boilers are fired from the top through a central stoking shoot, whilst others are fired from the side. The boiler tubes in some are horizontal, in others vertical, and in others again at an angle tb the vertical ; in the Leyland boiler thimble tubes are used similar to the well-known Clarkson boiler, being, in fact, made under a. Clarkson licence.

There is also a considerable variation in the type of valve gear used on the engine. The Sentinel and Leyland wagons have cam-operated poppet_ .valves,

similar to a petrol engine, whilst the Atkinson wagon employs the unifiow design with cam-operated 'ball valves for the admission of steam, the exhaust being controlled by the pistons uncovering ports in the middle of the cylinder bodies. In the Garrett and Clayton wagons piston valves are used on the engine, the former being operated by Joy valve gear and the latter by a single eccentric reversing gear mounted on a layshaft.

Only one type, the Brotherhood, uses a compound cylinder engine, although practically all the original undertype wagons used this type of engine. In the designs which have a direct drive from the engine crankshaft to the back axle it would be practically impossible to have compound cylinders, because of the large size which would be required due to-the engine rotating at such a comparatively slow speed.

It will be noted that both the live, or rotating, type of back axle and the fixed, or non-rotating, type are used. As in the case of petrol lorry practice, there is cons iderable diver gene e ef

n opinion as to the

merits of these two, types.

A superheater is fitted to the ifgrential boiler of all the Gear undertype wagons D<.ed Back Ai p now made, being in every case fitted in the top part. of the fur nace. This is a very necessary adjunct, because the engine cylinders of under type. wagons are not jacketed w i,t.h boiler steam like the overtype ; consequently, there is greater lose due to initial condensation of the steam when entering the cylinders. One of the chief merits of the undertype wagon is that, owing to the better layout of the units on the chassis, it is possible to obtain a short wheelbase ;• also a good distribution of the weight on the axles. The platform is long in proportion to the overall length of the wagon, and maximum loads can be carried voithout exceeding the axle weights laid down by the Heavy Motor Car Order. In all these feature,s the undertype wagon compares very favour

'ably with the petrol lorry, except for the greater weight carried on the front axle, due principally to the weight of the boiler. The total weight of the undertype is also low, because of the short chassis and close proximity of the power unit to the driving axle.

The open footplate and cab give a very comfortable position forthe driver, and, consequently, allow a larger mileage-to be accomplished with .less fatigue. The driver is well protected from the weather, but has plenty of ventilation, and is no subjected to extreme ,heat from the boiler, as this unit is well lagged, nor is oil likely to splash him.

All the controls are within

LEVEL WtTH easy reach, and one man can

FOOTPLATE

comfortably handle this type of wagon. The fuel bunker is conveniently situated, and the driver has a good view of the road to within a few yards of the front of the wagon without getting up off his seat. The engine being totally enclosed and running in an oil bath, with the dust effectively excluded from all the working parts, will run for long periods without adjustment or repair. As the lubrication is, practically speaking, automatic, there is no necessity for the driver to handle an oil feeder when running.

The Mechanical Efficiency of the Undertype.

Owing to the absence of gearing on most undertype wagons, and with the driving chain being of short length, the mechanical efficiency is very high. Even with wagons fitted with two-speed gear, all the gears are enclosed and run in oil, which redueee the mechanical efficiency by only a small amount. AR these features result in another great advantage— absence of noise. It is a well-known axiom that noise is the outward sign of wasted energy ; consequently, the quieter a wagon runs the greater is its mechanical efficiency.

The chassis of an undertype wagon is probably the simplest made, and the strongest ; Ackerman steering is easily accommodated, whilst the front end of • the wagon can be well sprung. The use to which ,motor wagons are put does not call for three-point suspension. Where the ground is too rough for fourspring suspension, it is much better to employ a separate tractor and trailers. The most important features of front-axle design are quick steering and. a large locking angle ; the former is necessitated by the higher speeds now allowed, and the latter by the greater congestion of traffi in the towns.

One of the greatest disadvantages of the undertype wagon is the inaccessibility of the engine, and also of the transmission gear where two speeds are used. When it becomes necessary to carry out any repairs to the engine, it is usually found more convenient to remove it bodily from the chassis. In order to do this the body must be removed before the unit can be slung out. Reference to the articles on overhauling steam wagons, published in The Commercial Motor in 1921, will illustrate this point clearly.

Tfie Boiler Awkward to Repair.

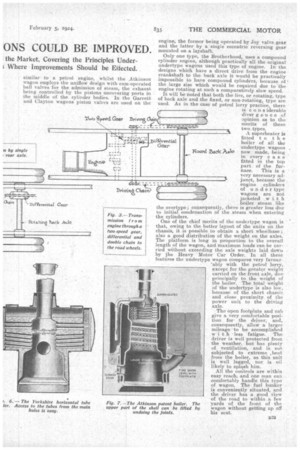

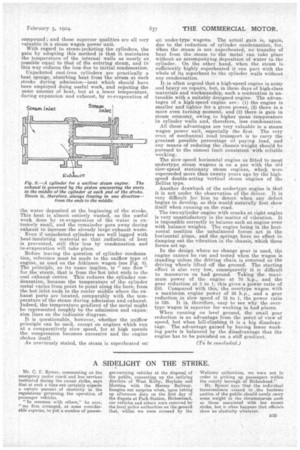

The boiler is also an awkward unit to repair, for, with the exception of the Garrett, it means either dropping the firebox right out, as with the Sentinel (see Fig. 4), or removing the top half of the shell, as with the Atkinson (see Fig. 7), before any repairs can be done to the tubes, which are the most vulnerable part of any boiler. Even the Garrett, with its front and back covers to remove, is a very awkward job compared with the loco-type boiler (see Fig. 5). One has to consider the number of nuts which have to be removed before breaking the joints whilst considerable care has to be exercised in replacing these parts in order to ensure that the joints shall be steam-tight. .

Apart from the question of accessibility, the vertical types of boilers used on undertype wagons are, in the writer's opinion, somewhat inferior in efficiency to the loco-type. This may seem a rather sweeping assertion to make, but a comparison of these units when ,climbing hills will bear out this statement.

The vertical boilers, because of their small combustion space, give best results as regards fuel consumption when using coke. The heating surface issin close proximity to the incandescent fuel, which is a necessary feature for coke, as all the heat is practically given off by radiation from the fire.

On the other hand, the loco.-type boiler•gives best results when burning coal, because of the larger combustion space and the long fire tubes, which can extract the heat from the hot volatile gases which this fuel gives off.

Coke requires either a much stronger draught or a larger grate area than coal. Roughly speaking, with B34

two boilers of equal grate area and using equal draught, twice the quantity of coal can be burned in a given time as compared with coke. Therefore, for a boiler burning coke to be of equal power to one burning coal, it must have either twice as much grate area or the draught must be -twice as strong. If the draught be increased, it means increased back pressure in the engine and less work done per lb. of fuel. Consequently, when ascending hills and pulling hard, the vertical boiler using coke is apt to be considerably overworked, which certainly reduces its efficiency.

When coal is used on the vertical boiler a large amount of heat is wasted up the funnel. The combustion of the gases is incomplete when they strike the water tubes, where they are quickly cooled, and much Of the heating value of the fuel passes away, unconsumed, in the shape of carbon monoxide.

The Need for Facilitating Stoking.

Another weak point with vertical boilers is the stoking. The driver cannot observe the state of the fire, as one, can with the loco-type, and, therefore, stoking is much more a matter of guess work, or, rather, is more dependent upon the skill of the driver.

One of the most convenient and efficient types of vertical boiler is the double-ended return-tube type first introduced on the Yorkshire wagon (see Fig. 6) and also used on the Brotherhood wagon. It is an easy boiler to repair, being even more accessible than the loco-type. Its chief drawback, as is the case with all other types of boilers, is its weight.

Boiler design is a very important factor in fuel economy, but, apart from the efficient generation of steam from the fuel, it is important that the steam should be economically used in the engine. ' The various methods which can be -adopted to give steam efficiency are as follow :— (1) Compounding the cylinders.

(2) Steam jacketing the cylinders.

(3) Superheating the steam. (4) Running the engine at high speed.

The proportion of useful work obtained per pound of steam depends upon working the steam expansively, so as to recover a portion of its internal energy, providing also that initial condensation and all other condensation can be reduced.

With the advent of high steam pressures (250 lb. per square inch in some cases), a large ratio of expansion is required in order to recover this internal energy in the steam. But there are three important objections to working steam at high pressure and large expansion in one cylinder, and these objections become more serious as the pressure and number of expansions . increase.

(1) The volume of the cylinder must be sufficient to provide for the required expansion of the steam, but it must also be sufficiently strong to carry the maximum pressures. Similarly, the working parts require to be large and strong to transmit the maximum stresees, and, since the maximum pressures and stresses are greatly in excess of the mean when the number of expansions is large, the engine becomes heavy compared with the power exerted.

(2) The loss by initial condensation increases rapidly as the number of expansions in one cylinder increases.

(3) The turning effort on the crankshaft becomes excessively variable with a large expansion ratio.

By using compound cylinders the range of stresses on the working parts, the loss by condensation, and the irregularity of turning effort are much reduced. Hence, for smoothness of working, with a wide range of pressures, and for economy of fuel, the compound engine is far superior to the non compound ; and these superior qualities are all very valuable in a steam wagon power unit. With regard to steam-jacketing the cylinders, the gain by adopting this method is that it maintains the temperature of the internal walls as nearly as possible equal to that of the entering steam, and in ' this way reduces the loss due to initial condensation, Unjacketed cast-iron cylinders are practically a heat sponge, absorbing beat from the steam at each stroke during admission—heat which should have been employed doing useful work, and rejecting the same amount of heat, but at a lower temperature, during expansion and exhaust, by re-evaporation of the water deposited at the beginning of the stroke.

• This heat is almost entirely wasted, as the useful work. done by re-evaporation of the water is extremely small, and the remainder goes away during exhaust to increase the already large exhaust waste.

• Even if unjacketed cylinders are well lagged with heat-insulating material so that radiation of heat is prevented, still this loss by condensation and re-evaporation will take place.

Before leaving the question of cylinder condense, tion, reference must be made to the uniflow type ot engine, as used on the Atkinson wagon (see Fig. 8). The principle, as its name implies, is "one flow" for the steam, that is from the -hot inlet ends to the cool exhaust centre. This reduces the cylinder condensation, because the temperature of the cylinder metal varies from point to point along the bore, from the hot inlet ends to the cooler middle where the exhaust ports are located, comparably with the temperature of the steam during admission and exhaust. Indeed, the temperature gradient of the metal might be represented roughly by the admission and expansion lines on the indicator diagram.

It is questionable, however, whether the uniflow principle can be used, except on engines which run at a comparatively slow speed, for at high speeds the compression becomes excessive and the engine chokes itself.

As previously stated, the steam is superheated one all under-type wagons. The actual gain is, again, due to the reduction of cylinder condensation for, when the steam is not superheated, no transfer of heat from the steam to the metal can take place without an accompanying deposition of water in the cylinder. On the other hand, when the steam is sufficiently highly superheated it•can part with the whole of its superheat to the cylinder walls without any condensation.

It is often argued that a high-speed engine is noisy and heavy on repairs, but., in these days of high-class materials and workmanship, such a contention is untenable with a suitably designed engine. The advantages of a high-speed engine arc: (1) the engine is smaller and lighter for a given power, (2) there is a more even turning moment, and (3) there is gain in steam economy, owing to higher mean temperature in cylinder walls arid, therefore, less condensation.

All these advantages are very valuable in a steam wagon power unit, especially the first. The very crux of mechanical road transport is to carry the greatest possible percentage of paying load, and any means of reducing the chassis weight should be pursued to the utmost limit consistent • with reliable working.

The slow-speed horizontal engine as fitted to most undertype steam wagons is on a par with the old slow-speed stationary steam engines, which were superseded more than twenty years ago by the highspeed double-acting vertical steam engines of the Bellies type.

Another drawback of the undertype engine is that it is not under the observation of the driver. It is very difficult for him to detect when any defect begins to develop, as this would naturally first show itself when running on.the road.

The two-cylinder engine with cranks at right angles is very unsatisfactory in the :matter of vibration. It is impossible correctly to balance such an engine even with balance weights. The engine being in the horizontal position the unbalanced forces act in the horizontal plane, and the springs have no effect in damping out the vibration in the chassis, which these forces set up.

In the deeign where no change gear is used, the engine cannot be run and tested when the wagon is standing unless the driving chain is removed or the driving wheels lifted off the ground. The starting i effort s also very low, consequently it is difficult to manceuvre on bad ground. Taking the maximum power of the engine at 70 h.p., and the gear reduction at 3 to 1, this gives a power ratio of 210. Compared with this, the overtype wagon with a maximum engine power of 35 h.p., and a gear reduction in slow speed of 15 to 1, the power ratio is 525. It is, therefore, easy to see why the overtype wagon is superior for working in bad places.

When running on level ground, the small gear reduction is an advantage from the point of view of speed, but when hill-climbing it is a big disadvan tage. The advantage gained by having fewer working parts is balanced by the disadvantage that the engine has to be punished on a stiff gradient.