GAS ATTACK

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

Forget the exhaust pipe; the Alfdex system is tackling crankcase gases by putting them to better use. Brian 1/1/eatherley reports.

Diesel exhaust emissions aren't the only noxious gases produced by a truck.A significant proportion of combustion gases don't even make it through the exhaust valve but end up in the crankcase having been blown back past the piston rings. In the past these blow-by gases were simply vented into the air; nowadays engine makers are reluctant to see them pass unhindered.

Diesels in CVs up to 3.5 tonnes GVW must incorporate a "closed" crankcase ventilation system, but there are no rules governing HGV diesels. However, most manufacturers are ahead of the legislators. 'Even though the Heavy Diesel Emission Directive as far as Euro-5 doesn't require us to consume crankcase gases, all Iveco engines do just as a good environmental practice," says Iveco's UK technical director Ken Moore.

Ray Cattley, Volvo Truck's UK manager for legislation and the environment, has not heard of any moves from Brussels to add crankcase gases to heavy truck emission regs, but he warns: "That's not to say it's not being discussed."

Not every truck manufacturer builds in a closed system.Although Scania's Vconfiguration diesels are all closed units, its in-line sixes are 'open', although they do fit a filter which separates the oil from the gases, dropping it back into the crankcase. Similarly, Volvo's "labyrinth" breathing system stops oil getting out while still allowing the crankcase to breathe.

With the growing use of EGR on diesel engines, especially in the US, the amount of 'dirty' gases being blown back into the crankcase is potentially increased, creating bigger problems for operators. With this in mind, truck component supplier Haldex and separation equipment specialist Alfa Laval have developed the Alfdex separation unit which removes the pollutants from diesel engine crankcase gases before returning them to the sump.

It is due to enter full production in 2005 with annual volumes of some 300,000 units expected by late 2008. Meanwhile, 300 Alfdex units are undergo ing field trials.

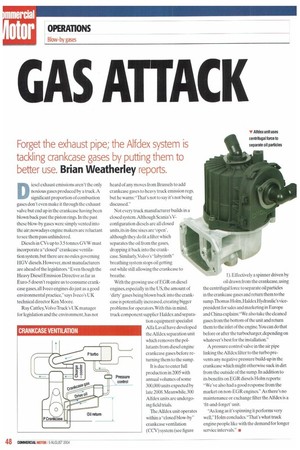

The Alfdex unit operates within a "closed blow-by" crankcase ventilation (CCV) system (see figure 1). Effectively a spinner driven by oil drawn from the crankcase, using the centrifugal force to separate oil particles in the crankcase gases and return them to the sump.Thomas Holm, Haldex Hydraulic's vicepresident for sales and marketing in Europe and China explains:"We also take the cleaned gases from the bottom of the unit and return them to the inlet of the engine. You can do that before or after the turbocharger, depending on whatever's best for the installation."

A pressure control valve in the air pipe linking the Alfdex filter to the turbo prevents any negative pressure build-up in the crankcase which might otherwise suck in dirt from the outside of the sump. In addition to its benefits on EGR diesels Holm reports: "We've also had a good response from the market on non-EGR engines." As there's no maintenance or exchange filter the Alfdex is a 'fit-and-forget' unit.

"As long as it's spinning it performs very well," Holm concludes."That's what truck engine people like with the demand for longer service intervals." •