MAKING TOOLS FROM SCRAP.

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

Handy Appliances Made by Our Driver and Mechanic Readers from Oddments.

IT is often easily possible to make useful additions to the equipment of a garage or workshop, thus considerably improving its efficiency if the foreman or the mechanic employed has sufficient ingenuity to enable him to devise and construct sundry small tools rand fittings from such oddments as arc, ,invariably to be found lying about in' any garage or workshop,

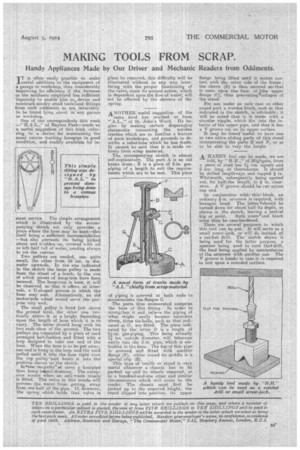

One of our correspondents this week —"H.A.L.," of Raynes Park—sends us a useful suggestion of this kind, referring to a device: for maintaining the Usual canvas washing hosepipe in good condition, and readily available for in stant service The simple arrangement which is illustrated by the accompanying sketch not only provides a place where the hose may be kept—this itself being a sufficient recommendation —but also prevents its being kicked about and trodden on, covered with oil or left half full of water, tending always to rot the canvas.

Two pulleys are needed, one quite small, the other from_ 18 ins, in diameter upwards. In the one indicated in the sketch the large pulley is made from the wheel of a truck, to the rim of which pieces of hoop-iron have been secured. The boon-iron is bent, it will be observed, so that it offers, at intervals, a U-shaped groove in .which the hose may rest. Alternatively,an old motorcycle wheel would serve the purpose very well.

The small pulley is fixed just above the ground level, the other one vertically above it at a height depending upon the length of hose which it is to carry. The latter should hang with its two ends clear of the ground. The two pulleys are connected by a piece of cord arranged belt-fashion and fitted with a loop designed to take one end of the hose. When the hose is to be put away, one end is hung in the loop and the cord pulled until it lifts the hose right ever the top pulley 'and hauls it into the position stiown on the sketch. •

In‘the 'majority's(' cases a hosepipe thus hung-iseaseif-draining. The camp-. eion occurs when an anti-waste nozzle is fitted. The valve in this nozzle will prevent the water from getting away from one-half of the pipe. If, however, the spring which holds that valve in

place be removed, this difficulty will be eliminated :without in any way interfering with the proper functioning of the valve, since its normal action, which is dependent upon the flow of water, will not be affected by the. absenee of the spring.

ANOTHER useful suggestion of the same kind has reached us from

" of St. John's Wood. He begins by making certain disparaging statements concerning the wooden trestles which are so familiar a feature of most workshops, and proceeds to describe a substitute which he has made. It cannot be said that it is made entirely from scrap material. The accompanying sketch is almost self-explanatory. The part A is an old brake drum.; B is a piece of 2-in, gaspiping of a length to suit the requirements which arc to be met. This piece of piping is screwed at both ends to accommodate the flanges C.

The parts thus enumerated comprise the base of this fitting. In order to strengthen it and relieve the piping of what might easily become • excessive stress, three tie-bolts, such as that indicated at. G, are fitted. The piece indicated by the letter D is a length of '14-in. gas-piping. . This being actually 11 ins, outside diameter, will telescope easily into the 2-in, pipe, which is embodied in the base. The top of this pipe is screwed and fitted with another flange (Fj, whilst round its middle is a special' clip (E).

This type of trestle or stand is very useful whenever a chassis has to be packed up and its wheels removed, or in a hundred-and-one other and similar eircurristances which will occur to the reader. The chassis must first be jacked up to the required height, the stand slipped into position, its upper

flange being lifted until it makes contact with the other side of the frame; the sleeve (E) is then secured sot that it rests upon the face of ;)the upper flange (C), thus preventing''collapse of the stand.

For use under an axle case or other round part a wooden block, such as that indicated in the sketch, is advisable; it will be noted that it is made with a circular nipple, which fits into the interior of the upper pipe, and that it has a V groove cut on its upper surface.

It may be fountruseful to have one or two extra sliding parts of this stand incorporating the parts E and F, so as to be able to vary the height A. HANDY tool can be made, we are told, by-' H-H.," of Highgate, from a piece of steel her 74 ins. square and 2 ins, long, or thereabouts. It should he drilled lengthways and tapped in, Whitworth, subsequently being opened out, for half..the length, to a in. clearance. A V groove should,be cut• across one end.

In conjunction withthis block, an ordinary fin. setscrew is required, with hexagon head. The latter should be turned down for about half its depth, as shown in the sketch, leaving a central hip or point. Both screw? and block must then be case-hardened.

There are several purposes to which this tool can be put. It will serve as a small screw-jack, or will do instead, of a ratchet drill. The' sketch shows it being used for the latter purpose, D spanner being used to turn thee drill, the feed being applied by manipulation of the setscrew with another one. The V groove is handy in case it is required to rest upon a rounded surface.