• THE LATEST FRENCH GAS-PRODUCER.

Page 11

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

' Details of the New Machine Produced by Panhard and Levassor, Together with the Most Important of the Test Results,

MITE 'USE of charcoal gas for indus1, trial motor vehicles continues to make solid progress in France. One after another the great French, motormanufacturing firms are . taking the matter up in response to the growing overseas demand for suitable gas instnilations. Even in France itself the commercial vehicle user in country distriets is beginning to show an interest in the new fuel.

The latest gas-producer to he placed on the market emanates from the famous firm of Panhard and Levassor. Most of these machines have a &dein family resemblance on account of the principle employed. Each, however, has its particular features, and in the Panhard appliance the pnint aimed at has been simplicity and a great reduction in the number of parts.

The Panhard apparatus comprises three main portions only. There ie the usual combined furnace and fuel hopper, located on one side of the lorry and the gas purifier, or scrubber, on the other side, the two being joined by a series of pipes which forms the gas cooler.

These pipes are ten in number, and are placed horizontally in two layers of five. They are completely exposed; and get the benefit of the air passing underneath the lorry.

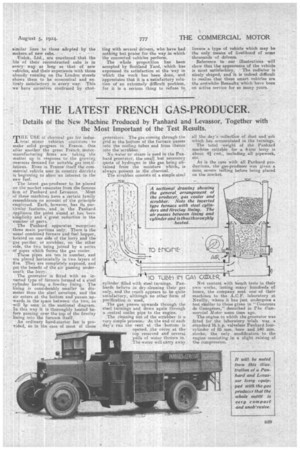

The generator is fitted with an inverted type of furnace formed of a steel cylinder having a fireclay lining. The i

lining is considerably smaller n diameter than the steel envelope, and the air enters at the bottom and passes upwards in the space between the two, aswill he seen in the sectional diagram. In this way it is thoroughly heated before passing over the eop of the fireclay lining into the furnace itself.

An ordinary hand-starter fan is provided, as in the case of most of these generators. The gas coming through the grid at the bottom of the furnace passes into the cooling tubes and from thence into the scrubber. • • • No water or steam is used in the Panhard generator, the small but necessary quota of hydrogen in the gas being ehtaMed from the 'moisture "which, is always present in the charcoal The scrubber consists of a simple steel

• cylinder filled with steel turnings. Panherds believe in dry-cleaning their gas only, and the result appears to be quite satisfactory, although no other form of purification is used.

The gas, passes upwards through the steel turnings and down again through a central outlet pipe to the engine.

The cleaning out of the scrubber is a very simple process, At the end of each day's run the vent at the bottom is opened, the cover at the top removed and several pails of water thrown in. The writer will carry away all the day's collection of dust and ash which has accumulated in the turnings.

The total weight of the Panhard machine suitable for a 4-ton lorry is about 4,4 cwt., including all pipework, etc.

As is the case with all Panhard productions, the gas-producer was given a most severe testing before being placed on the market.

Not content with bench tests in their own works, lasting many hundreds of hours, the company sent one of their machines to the A.C.F. laboratory at Neuilly, where it has just undergone a test similar to those given in " Concours de Gazogenes," described in The Commercial Motor some time ago.

The engine to which the generator was fitted for the laboratory trials was a standard 16 h.p. valveless Panhard fourcylinder of 85 mm. bore and 140 .mm. stroke, the only modification to the engine consisting in a slight raising of the compression. The fuel consumption during these trials was found to be 430 grammes of charcoal per h.p.-bour, and the average power obtained during six hours was 23.33 b.h.p. The engine speed was about 1,180 r.p as. The total fuel consumption in six hours' running was 60.2 kg. of charcoal.

-The composition of the gas was found to be ;—

CO/ ... 3 Oxygen ... 0.5 In percentage of Carbon monoxide 27 volume. Hydrogen The calorific value of the gas, measured by a Junker's calorimeter, proved to be 1.075 calories, Apart from bench tests, it is worthy of note that a Panhard lorry fitted with the gas-producer has now been in constant service for three months, running between the Panhard-Levassor works at Ivry, in Paris, and the branch establishment at Rheims.

• The vehicle in question is a standard 4-ton Panhard lorry ("4 tonnes Francaises useful load "). The total weight of the lorry with iis load is about 7 tons. The run is 130 miles or more over a fair give-and-take road with plenty of hills. On this regular trip the lorry averages 43 kilos of charcoal to the 100 or about 1.4 lb. to the mile. The average speed maintained on the trip is about 12L m.p.h. This sounds a fairly high average speed for a 4-ton lorry, but. it may be noted that the vehicle runs on pneumatic tyres.

The usual double-connection arrangement for starting up on petrol is made to the engine on this lorry.