m Drivers &Mechanics

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY is paid for the best communication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

Light Up Your Lamps At

8.41 on Thursday ; 8.39 on Friday; 8.38 on Saturday; 8.35 on Monday ; 8.33 on Tuesday; 8.31 on Wednesday.

Casting a Piston with an Improvised Corebox.

The sender of the following communication has been awarded the 10s. prize this week.

[1655] "H.M." (West Bromwich) writes :—" When overhauling an old engine recently it was found necessary to rebore one of the cylinders. As is usual with such jobs, the machine was wanted to be put back

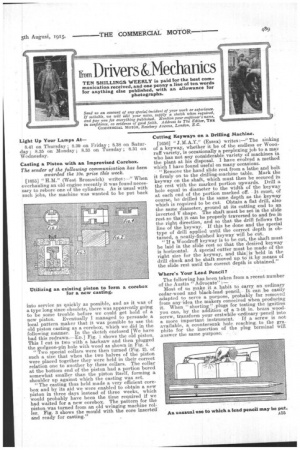

into service as quickly as possible, and as it was of a type long since obsolete, there was apparently going to be some trouble before we could get hold of a new piston. Eventually I managed to persuade a local pattern maker that it was possible to use the old piston casting as a corebox, which we did in the following manner. In the sketch enclosed [We have had this redrawn.—En.] Fig. 1 shows the old piston. This I cut in two with a hacksaw and then plugged the gudgeon-pin hole with wood as shown in Fig. 4.

"Two special collars were then turned (Fig. 2), of such a size that when the two halves of the piston were placed together they were held in their correct relation one to another by these collars. The collar at the bottom end of the piston had a portion bored somewhat smaller than the piston itself, forming a shoulder up against which the casting was set. "The casting thus held made a very efficient corebox and by its aid we were enabled to obtain a new piston in three days instead of three weeks, which would probably have been the time required if we had waited for a new corebox. The pattern for the piston was turned from an old wringing machine roller. Fig. 3 shows the mould with the core inserted and ready for casting." Cutting Keyways on a Drilling Machine.

[1656] " J.3.I.A.Y." (Essex) writes:—" The sinking of a keyway, whether it be of the endless or Woociruff variety, is occasionally a perplexing job to a maa. who has not any considerable variety of machines in the plant at his disposal. I have evolved a method which I have found useful on many occasions.

"Remove the hand slide rest from a lathe and bolt it firmly on to the drilling-machine table. Mark the keyway on the shaft, which must then be secured in the rest with the marked portion upwards. Drill a hole equal in diameter to the width of the keyway at each end of the portion marked off. It must, of course, be drilled to the same depth as the keyway which is required to be cut. Obtain a flat drill, also the same diameter, ground at its cutting end to an inverted V shape. The shaft must be set in the slide rest so that it can be properly traversed to and from the right direction, and so that the drill follows the line of the keyway. If this be done and the special type of drill applied until the correct depth is obtained, a neatly-finished keyway will be cut.

"If a Woodruff keyway is to be cut, the shaft must be laid in the slide rest so that the desired keyway is horizontal. A special cutter must be made of the right size for the keyway, and this..-is 'held in the drill chuck and he shaft moved up to it by means of the slide rest until the correct depth is obtained."

Where's Your Lead Pencil ?

The following has been taken from a recent number of the Austin " Advocate" :—

Most of us make it a habit to carry an ordinary cedar-wood and black-lead pencil. It can be easily adapted to serve a purpose, probably far removed from any 'idea the makers c,onceived when producing it. When "shorting " plugs for testing the ignition you can, by the addition of a-3-16 in. brass woodscrew, transform your erstwhile 'ordinary -pencil into a more important instrument. If a screw is not available, a countereunk hole reaching., to the graphite for the insertion of the plug terminal will answer the same purpose.