Tanker converted for bottom loading

Page 10

If you've noticed an error in this article please click here to report it so we can fix it.

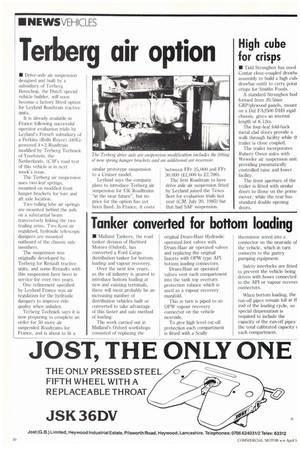

• Midland Tankers, the road tanker division of Hartford Motors (Oxford), has converted a Ford Cargo distribution tanker for bottom loading and vapour recovery.

Over the next few years, as the oil industry is geared to introduce bottom loading at new and existing terminals, there will most probably be an increasing number of distribution vehicles built or converted to take advantage of this faster and safe method of loading.

The work carried out in Midland's Oxford workshops consisted of replacing the original Drum-Haar Hydraulic operated foot valves with Drum-Haar air operated valves and replacing the original faucets with OPW type API bottom loading connectors.

Drum-Haar air operated valves vent each compartment into the tank top overturn protection valance which is used as a vapour recovery manifold.

This in turn is piped to an OPW vapour recovery connector on the vehicle nearside.

To give high level cut-off protection each compartment is fitted with a Scully thermistor wired into a connector on the nearside of the vehicle, which in turn connects to the gantry pumping equipment.

Safety interlocks are fitted to prevent the vehicle being driven with hoses connected to the API or vapour recovei connectors.

When bottom loading, the run-off pipes remain full at tlend of the loading cycle, so special dispensation is required to include the capacity of the run-off pipes the total calibrated capacity ( each compartment.