A NEW ENGINE FOR COACHES AND BUSES.

Page 13

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

Details of a Most Interesting Daimler Power Unit Designed To Give Longer Life and Greater Power. It Embodies a Special System of Lubrication Which Has Been Most Carefully Considered.

FOR the past three years the Daimler Co., Ltd., of Coventry, has been an active participant in the affairs of the Associated Daimler Co., Ltd. Now, however, there has been a reversion to its original status as manufacturer of complete vehicles for commercial purposes. The company also has its own selling organization, which is in the capable hands of Mr„..Y. G. Couch, who has long been in the service of his present employer.

The first modification which the newly organized managerial staff has deemed necessary is the introduction of a more powerful and robust engine. When it is realized that that well-known automobile engineer—Mr. L. H. Pomeroy—who, by the way, has recently spent several years in the U.S.A. upon technical investigations, has been actively connected with the development of the new nnit, it can be taken for granted that the inclusion of any special feature has been fully justified by experience.

As everyone connected with the coach or bus industry knows, speed, or, at least, the demand of operators for faster and faster vehicles, has greatly increased lately and the standard of performance has, in consequence, risen considerably, even during the past year. With careful forethought, the Daimler Co. has realized this, and in order to be right up to date—a requirement that appears to be well to the fore in the minds of the designers—is introducing a new power unit to replace the engine that has been uSed during the present year.

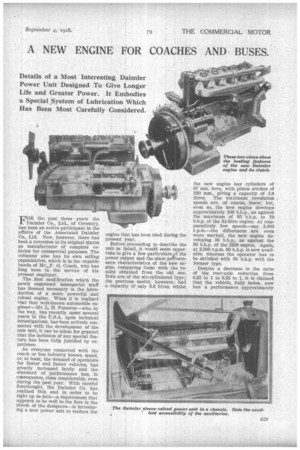

Before proceeding to describe the unit in detail, it would seem opportune to give a 'few particularssf the power output and the niain performance characteristics of the new engine, comparing these with the results obtained from the old one. Both are of the six-cylindered typo; the previous model, however, had a capacity of only 3.6 litres, whilst

the new engine has cylinders of 97 ram. bore, with piston strokes of 130 mm., giving a capacity of 5.6 litres. The maximum revolution speeds are, of course, lower, but, even so, the new engine develops approximately 100 b.h.p., as against the maximum of 65 b.h.p. to 70 b.h.p. of the 3i-litre engine. At comparatively low speeds—say 1,000 r.p.m.—the differences are even more marked, the new engine developing 50 b.h.p., as against the 30 b.h.p. of the 1928 engine. Again, at 2,000 r.p.m. 90 b.h.p. is now available, whereas the operator has to be satisfied with 60 b.h.p. with the former type.

. Despite a decrease in the ratio of the rear-axle reduction from 825 to 1 to 6.25 to 1, it is claimed that the vehicle, fully laden, now has a performance approximately 30 per cent, better than its prototype, whilst, of course, the maximum speed and the ideal cruising speed are also much higher.

Looking at the engine from either side, one is immediately struck by the extraordinary clean lines of the layout, yet all vulnerable parts are _ readily accessible. The oil filler is quite handy and the oil filter, which incidentally, is of the Zenith disc petrol-fitter type (only, of course, much larger), is also conveniently placed, whilst the dynamo, starter, motor and carburetter are all fitted in such positions that, in the event of an adjustment or repair being necessary, only the components themselves have to be dismantled in order to obtain access to the vulnerable parts.

One other item .might be mentioned. If it be desired at any time to remove a piston--often a difficult job on a sleeve-valved engine— it is only necessary to follow the normal procedure of dropping the sump, removing the connecting-rod` bolts and pushing the piston, complete with the connecting rod, up through the cylinder, bore. The cylinder head must, of course, be first removed.

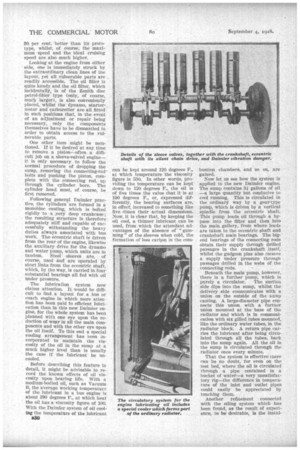

Following general Daimler practice, the cylinders are formed in a monobloc casting, which is bolted rigidly to a .yery deep crankcase; the resulting structure is therefore adequately stiff and capable of successfully withstanding the heavy duties always associated with bus work. The eccentric shaft is driven from the rear of the engine, likewise the auxiliary drive for the dynamo and water pump, which units are in tandem. Steel sleeves are, of course, used and are operated by short links from the eccentric shaft, which, by the way, is carried in four substantial bearings all fed with oil under pressure.

The lubrication system now claims attention. It would be difficult to find a layout for a bus or coach engine in which more atten. tion has been paid to efficient lubrication than in this new Daimler engine, for the whole system has been planned with one eye upon the reduction of wear in all the main components and with the other eye upon the oil itself. To this end a special cooling arrangement has been incorporated to maintain the viscosity of the oil in the stomp at a much higher level than is usually the Case if the lubricant be nncooled.

Before describing this feature in detail, it might be advisable to record the known effects of oil viscosity upon bearing life. With a medium-bodied oil, such as Vacuum B, the average working temperature of the lubricant in a bus engine is about 190 degrees F., at which heat

the oil has a viscosity figure of 100. With the Daimler system of oil cooling the temperature a the lubricant 530

can be kept around 120 degrees F., at which temperature the viscosity figure is 550. In other words, providing the temperature can be kept down to 120 degrees F., the oil is of five times the value that it is at 100 degrees F., or, expressed differently, the bearing surfaces are, in effect, increased to something like five -times their actual dimensions. Now, it is clear that, by keeping the oil cool, a thinner lubricant can be used, from which the attendant advantages of the absence of " gumming " of the sleeves when cold, the formation of less carbon in the corn bustion chambers, and so on, are gained. Now let us see how the system is applied to the new Daimler engine. The sump contains 3i gallons of oil —a large quantity but conducive to cool running. This is circulated in

the ordinary way by a gear-type pump, which is driven by a vertical spindle from the eccentric shaft. This pump leads oil through a bypass into the filter and then into the main gallery, from where leads are taken to the eccentric shaft and crankshaft main bearings. The bigend bearings of the connecting rods obtain their supply through drilled passages in the crankshaft iteelf, whilst the gudgeon pins also receive a supply under pressure through-1. passages drilled in the webs of the connecting rods.

Beneath the main pump, however, there is a further pump, which is purely a circulator. The suction side dips into the sump, whilst the delivery side communicates with a union on the outside of the sump casting. A large-diameter pipe connects this union with a further union mounted at the base of the radiator and which is in communication with six gilled tubes mounted, like the ordinary water tubes, in the radiator block. A return pipe carries the lubricant after being circulated through all the tubes, back into the sump again. All the oil in the sump is circulated through the radiator once every minute.

That the system is effective lucre can be no doubt, for even on the test bed, where the oil is circulated through a pipe contained in a bucket of water—a very unsatisfactory rig—the difference in temperature of the inlet and outlet pipes could easily be appreciated by touching them.

Another refinement connected with the oiling system which has been found, as the result of experience, to be desirable, is the instal lation of a special type of oil primer. The sleeve-valved engine is, of course, particularly prone to become starved of oil if a high-pressure lubrication system be used, because the sleeves have such a large area. When the engine is stone cold and the oil is, in consequence, very thick, there is practically ho escape from the big-end bearings to splash on to the cylinder and sleeve walls. The engine soon becomes warm, however, and the sleeves quickly obtain the necessary supply of oil to enable them to function sweetly. It is, however, during the first minute or so after the engine has been started up that damage may be done to either the sleeves or the pistons.

To circumvent all possible trouble from this cause, the new Daimler engine incorporates a practically foolproof oil-priming arrangement. Connected with the 'starter switch is a lever which operates a ball valve in the main oil-delivery line, thus by-passing a percentage of the circulating lubricant into a pipe communicating with. the base of each cylinder. Now, when the pistons are at top dead centre, oil is squirted into the cylinders and on to the connecting rods, whence, by centrifugal force, it is flung' up on to the sleeves and pistons, thereby ensuring a definite supply to these somewhat vulnerable points.

While at the Daimler works we had an opportunity of witnessing how efficient this priming action is, for with a stone-cold engine and absolutely dry components, the cylinders, and even the junk heads, were thoroughly lubricated after running the engine for only a minute. As soon as the engine has Warmed up sufficiently for proper circulation to be started, a trip lever fitted to the dash enables the prim lag to be stopped. The lever is fitted in an obtrusive position, so that it is unlikely that the driver will forget to turn it off.

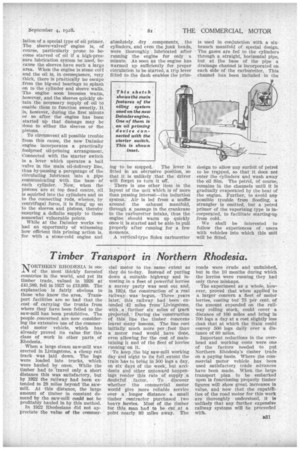

There is one other item in the layout of the unit which is of more than passing interest—the induction system. Air is led from a muffle around the exhaust manifold, through a passage in the crankcase to 'the carburetter intake, thus the engine should warm up quickly once it is started and be able to pull properly after running for a few moments.

A vertical-type Solex carburettec is used in conjunction with a sixbranch manifold of special design. The gases are fed to the cylinders through a straight, horizontal pipe, but at the base of the pipe a drainage channel is incorporated on each side of the carburetter. This channel has been included in the

design to allow any surfeit of petrol to be trapped, so that it does not enter the cylinders and wash away the oil film. The petrol, of course, remains in the channels until it is gradually evaporated by the heat of the engine. Further, to avoid any possible trouble from flooding, a strangler is omitted, but a petrol primer of the vaporizing type is Incorporated, to facilitate starting-up from cold.

We shall be interested to follow the experiences of users with vehicles into which this unit will be fitted.