HINTS ABOUT ROAD SPRINGS.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

Some Valuable Tips from Our Driver and Mechanic Readers.

ONE. of our driver readers, " H.T.O.," of Rochford, found himself in a bit of a difficulty the other day_ He had one or two heavy rear springs to repair, fitting each of them with new leaves—a familiar job. He managed to get the springs apart easily enough, and, to locate the new leaves, each in proper relation to the rest, but

came to a full stop when he was ready to put the springs together again. •He had no tools by which this operation' could easily be carried out, and, for the moment, was at a loss to know how to tackle the job. Eventually, however, he managed to complete the task, and in rather an ingenious manner. For his description of it, and the accompanying sketches, we are awarding him the 15s. prize this week.

He rested the spring, right way up, on a couple of boxes; looaely binding the leaves with string so that the short ones would not fall to the ground. On the top he placed a couple of wooden blocks, spaced about 15 ins. apart, and on these again rested another fairly substantial baulk of timber, laying it longitudinally in line with the spring itself. This last served as a support for a serew-_ jack, as shown. Round the lot—spring, blocks of wood, and jack—be wound a cycle chain, joining its ends in the orthodox manner. Then, by manipulating the jack he was able to close the spring up and fit the central bolt.

Another way of doing the same job would have been, as he says, to mount jack; blocks, and spring in a doorway as shown in the second sketch. The mode of operation in this cabs is obvious.

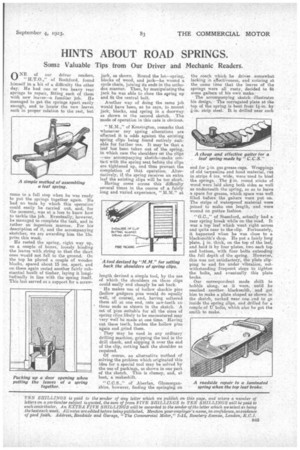

"MM.," of Kensington, remarks that whenever any spring alterations are effected it is odds against the existing spring clips being found entirely Suitable for further use. It may be that a leaf Kai been taken out of the spring, in which case the shoulders on the clips .-see accompanying sketch—make conta,et with the spring seat before the clips are tightened up, and thus prevent the completion of that operation. Alternatively, if the spring receives an extra leaf the existing clips will be too short. Having come across this difficulty several times in the course of a fairly long and varied experience, " M.M." at length devised a simple tool, by the use of which the shoulders on these clips could easily and cheaply be set back.

He makes use of hollow shackle pins (hollow gudgeon pins would do equally Well, of course), and, having stiffened them all at one end, cuts saw-teeth cn those ends as shOwn in the sketch. A set of pins suitable for all the sizes of spring dins likely to be encountered may very well be made at one time. Having cut these teeth, harden the hollow pins again and grind them. , • They may be used in any ordinary drilling machine, gripping the tool in the drill chuck, and slipping it over the end of the clip, cutting hack the shoulder as required.

Of course, an alternative method of solving the problem which originated this idea for a special tool may be solved by the use of packings, as shown in one part of the sketch. This is clumsy, and, at best, a makeshift.

"I" of Aberfan, Glamorgan the coach which he drives somewhat lacking -in effectiveness and noticing at the same time that die leaves of the springs were all rusty, decided to fit some gaiters of his own make.

The accompanying sketch illustrates his design. The corrugated plate at the top of the spring is bent from 14-in. by 4-in. strip steel. It is drilled near each

end for g-.1.11. gas grease caps. Wrappings of old tarpaulins and hood material, cut in strips 4 ins, wide, were used to bind the springs. The kin. round sticks of wood were laid along both sides as well as underneath the spring, so as to leave a space for grease, which space was well filled before the gaiters were put on. The strips of waterproof material were joined to make one length, and were

wound on puttee fashion.

"GO.," of Stamford, actually had a rear spring break while on the road. It was a top" leaf which went right across and quite near to the clip. Fortunately, it happened when he was close to a blacksmith's shop. He put a fairly long plate. Is in. thick, on the top of the leaf, and held it by four plates, two each top and bottom, with four bolts extending the full depth of the spring. However, this was not satisfactory, the plate slipping to and fro under vibration, notwithstanding frequent slops to tighten the bolts, and eventually this plate broke.

Our correspondent made shift to hobble along, as it were, until he reached another blacksmith, and got him to make a plate shaped as shown in the sketch, necked near one end to go inside the spring clips, and drilled for a couple of U bolts, which also he got the smith to make.