HINTS ON MAINTENANCE.

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

419.—Repairing White-metal Bearing Liners.

When adjusling and rebedding the liners for the metal bearings of connecting reds and crankshafts, particular care should be taken that the oil-feed ho es in the liners correspond with those in their housings. Should the holes not correspond the trouble may be traced to the securing peg, which ma,y, through the continual drag of the revolving shaft, have elongated the holes in the liners and allowed them to turn slightly, so blacking the feed holes. To remedy the trouble in any particular case fill in the elongated holes with solder, using Baker's fluid as a flux. Now take an old i-in. twist drill, ground flat on its cutting edge, and use as an end mill to open out the peg hole (B), taking care not to go deeper than the original hole. Into the opening thus made, fit tightly a piece of brass rod, which should be soldered into position. Through the centre of this rod drill a hole the same diameter as the peg. It may be found preferable to bore the rod before it, is inserted in the hole. The bush thus formed should be trimmed with a file until it is flush with the external face of the liner.

420.—The Lubrication of the 30-45-cwt. Napier.

The oil in the Napier engine is delivered to the crankshaft bearings from a gear-type pump located in the sump and driven from the cqmshaft through skew gears. Oil is passed through a filter to the main bearings, and thence through the hollow crankshaft to the connecting rods. Baffle plates are provided and prevent an excess reaching the cylinders.

There is a valve for regulating the pressure of oil to the bearings, but this is carefully adjusted and will probably need no attention unless the vehicle has been used for a very Jong time. The pump and filter are constructed as a unit and can readily be removed for attention. The strainer in the circulating system should be cleaned regularly once a month.

If the pressure gauge on the dashboard at any time does not register any pressure, the engine should not be run for more than a few seconds at a time until the trouble has been rectified. If the trouble cannot 544 be traced, three gallons of oil should be put into the engine and the vehicle then run slowly home. This amount of oil permits of splash lubrication.

421.—Improving the Suspension of the Engine on the Sentinel Steam Wagon.

At the pump side of the engine on the Sentinel steam wagon is a special suspension plate with a lip bent over the chassis frame. The crankcase is held to the suspension plate by. tin. nuts screwed on to studs in the former and round the hole for the hand cover. Ti great care be not exercised in keeping these nuts tight, the engine soon begins to work loose in the holes drilled in the suspension plate. These holes are drilled clearance, and the studs may be somewhat loose in the holes, even when the plate is new. Therefore, to prevent wear, it is advisable to reamer the holes ism. diameter and to use five special studs for the crankcase, these being screwed in. for the last-named, and left with a 1-in. thread to pass through the plate.

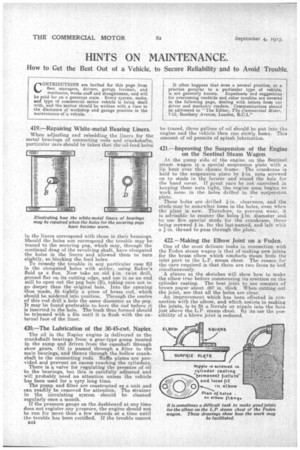

422.—Making the Elbow Joint on a -Foden.

One of the most delicate tasks in connection with the Foden steam wagon is that of making new joints for the brass elbow which conducts steam from the inlet port to the L.P. steam chest. The reason for the care required is that there are two faces to bed rim ultaneously.

A glance at the sketches will show how to make the elbow true before commencing its erection on the cylinder casting. The best joint to use consists of brown paper about .007 in. thick When cutting out the joint, see that all the holes are clear. An improvement which has been effected in connection with the elbow, and which assists in making the joints, is to fit a, ferrule or nipple into the hole just above the L.P. steam cheat. By its use the possibility of a blown joint is reduced.